B. Specifications

Input Impedance

Min.

Typ.

Max.

Units

4

5

Input Signal Level

Gain: Continuously

Adjustable: Input 5

Input 4

Output

Output Current

20

Ω

load

Output current limits

Dither current adjustable

Output drift at max. gain

During warm-up (30 min.)

vs. temperature

vs. time (after 30 min.)

vs. supply voltage

4.95

49.5

–100

2

0.20

20

–20

3

Frequency Response

DC - 300 Hz max.

gain full load

Single ended with respect to common

5

50

0

200

5.05

50.5

+100

20

2

400

500

100

30

1

10

1

–3

K

Ω

K

Ω

V-peak

Amps/volt

Amps/volt

MA

MA

MAp-p

MA

MA/

_

F

MA/24 hrs.

MA

DB

Regulated Output

Supply into 500 Ohm load

Pin 7 to common

Pin 8 to common

Temperature Range

Operating

Storage

Power Supply Req’mnt

Voltage Range

+9

–9

–29

–40

+14

–14

+10

–10

+19

–19

+11

–11

+71

+85

+20

–20

Vdc

Vdc

_

C

_

C

Vdc

Vdc

Mechanical Specs

Module

Module Size

Module Weight

Controls

Special printed circuit card

5.0” x 3.5” x 1.0”

8 ox.

Screwdriver adjusted

Dither

Gain

Table 1. Electrical and Mechanical Specifications for the EM-A-10.

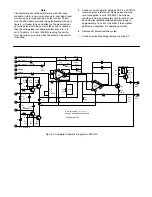

General

This manual is written primarily to establish a logical trouble-

shooting procedure for the solid state EM (electronic modular)

amplifier. Complete systems are beyond the scope of this manual

and will not be covered. Adequate information is presented for an

Electrical Technician to repair the EM-A-10 amplifier.

EM-A-10 (308118) Linear Servo Amplifier

A. Description

The EM-A-10 is a special purpose DC servo amplifier designed

specifically for a Vickers SE3 or SF4 flapper type servo valve.

The EM-A-10 consists of a high gain summing amplifier, a low

gain DC amplifier and a power output stage.

The amplifier module also contains a

10 volt regulated power

supply which may be used for development of input signals

through an external 5000 ohm potentiometer.

The complete amplifier and power supply are contained on a

plug-in module whose approximate dimensions are 3-1/2 x 5

inches. Refer to table 1 for electrical and mechanical

specifications.

C. Installation

The EM-A-10 servo amplifier is designed for mounting

on a power supply plate such as the EMP-A-11. Input

and output connections to the amplifier circuitry are

provided by printed circuit pin connections on the

module. These pin connections, when installed into a

plug-in receptacle, must be connected as shown in Table

2. TB2 wiring interconnections, located on the EMP-A-11

power supply plate, are shown for convenience.

Portions of the EM–A-10 servo amplifier are of the

incapsulated construction and must be replaced as

complete assemblies. Amplifier A1 and A2 shown on the

schematic diagram Figure 1 are examples of this type of

construction. Replacement of A1 and A2 require factory

adjustments to be performed to the resistance values

designated by an asterisk (*). Therefore, should

replacement of either amplifier be required, it is

recommended that the installation be accomplished by

Vickers. Replacement EM-A-10 amplifiers are available.

EMP-A-11

TB2

(J)A

(J)B

(J)C

Plug-in

receptacle

pin

conn’tions

Plug-in

module

pin

conn’tions

Signal

–

–

–

4

5

6

7

8

–

–

1

2

–

–

3

a

b

c

d

e

f

h

j

k

l

m

n

p

r

s

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

Dither (13 Vac)

N.C

–19 Vdc input

Input #1

Input #2

Summing Junction

RegDC output

Regulated –DC output

N.C.

N.C.

Negative output to coil

Positive output to coil

+19 Vdc input

Slotted for polarizing

key

Common

Table 2. The EM-A-10 Plug-in Receptacle and

Terminal Board Interconnecting Wiring

D. Circuit Description

Amplifier Section - The EM-A-10 is a DC amplifier,

consisting of a high gain summing pre-amplifier feeding a

unity gain buffer amplifier which drives a power output

stage.

The output stage is statically adjusted to produce 200

Milliamperes (MA) of current through the 20

Ω

servo

valve coil. (Vickers type SE3/SF4 servo valve) and varies

from this 200 MA value with variations in input signal.

An explanation of the circuitry follows: Refer to the

pictorial diagram, Figure 1, the simplified schematic

diagram Figure 2, and the complete schematic diagram

schematic diagram Figure 3.