22

23

INM MTL9373-FB3 Rev 1

INM MTL9373-FB3 Rev 1

1) Disconnect the red (+), black (–) and yellow/green wires of the TP-32 module. The

+ and – will either be on the Fieldbus Barrier or on the DIN rail terminals,

depending upon the enclosure type. The yellow/green wire will be connected via a

ring terminal to the M6 grounding stud.

2) The bracket is held in place with two nuts on M6 studs. Loosen and remove these

nuts to detach the bracket from the enclosure.

3) Loosen and remove the retaining nut to free the TP-32 from its mounting bracket.

Fitting a replacement TP-32 is the reverse of the removal procedure. Torque the M6 nuts

to 4.5Nm (3.3lbft).

Connect the TP-32 wires in the same manner as before its removal – refer to Figures 5.4

and 5.7 and the table below for additional details.

TP-32 wires

TRUNK OUT

connector

Trunk In DIN rail

connector

Red

+

+

Black

-

-

The yellow and green stripe wire on the TP-32 should be connected to the protective

grounding stud located beside it. DO NOT connect this wire to the ‘S’ terminal of the

trunk connector.

Before refitting the Trunk wiring protective cover:

• Check all wiring connections

• Confirm that the Grounding link is in accordance with the Option required

• Check that the Terminator link is in the correct position

Replace the transparent protective cover over the terminal block and ensure that there is

positive engagement of the retaining clip.

6.6 Regular Maintenance checks

Check the general condition of the installation occasionally to ensure that no

deterioration has occurred. At least every two years (and more frequently for harsh,

dusty or dirty environments) check:

• Clean only with a moist cloth and detergent.

• the condition of all wire connections/terminations/screens

• that all of the fixing and cover screws and blanking plugs are secure and the

enclosure breather/drain is clear

• that there are no signs of damage or corrosion

• that the level of any accumulated dust on the barrier enclosure does not

exceed 5mm

In addition, take advantage of plant maintenance shutdown periods or whenever the

area is known to be non-hazardous, to check wiring quality by ensuring that the dc

voltage on the fieldbus trunk, when measured at the enclosure, is >16V. This can be

performed using a multimeter or an FBT-6 fieldbus tester.

7

TROUBLESHOOTING

Each Fieldbus Barrier module is fitted with LED indicators to assist the user with

fault identification.

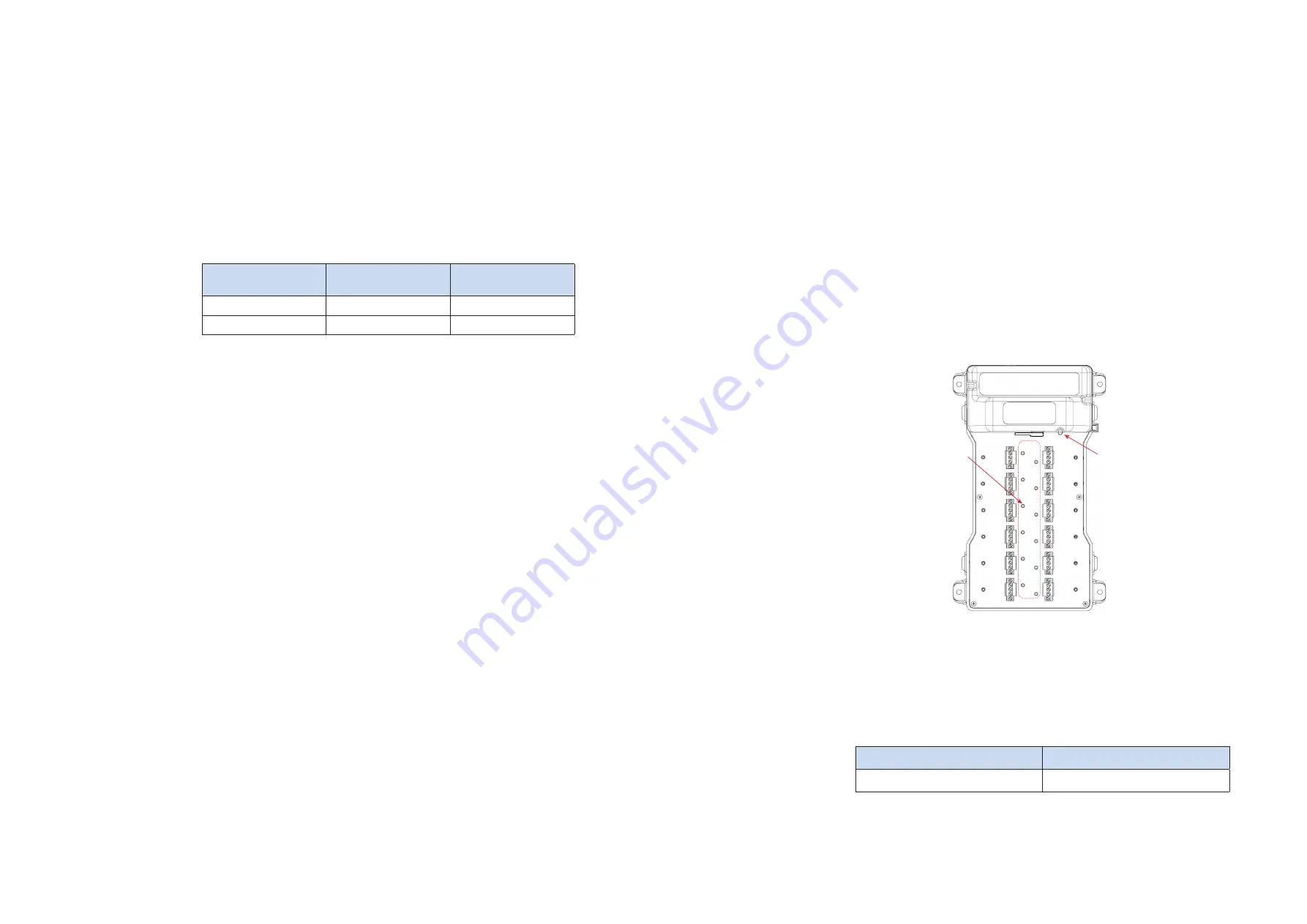

Figure 7.1

–Barrier LED locations

Consult the following tables to understand the meaning of the LED states.

Power LED (Green)

ON

OFF

Trunk power applied

Insufficient or no trunk power

Power LED

Spur LEDs