IOM 570 06/2011

REV A.

Page 2 of 8

E

aton Hydraulics LLC, Filtration Division, 44 Apple Street, Tinton Falls, NJ 07724, www.eaton.com/filtration, Phone 732-212-4700

Installation, Operation & Maintenance Manual

Model 570 Duplex Basket Strainer

RECEIVING,

HANDLING

AND

INSPECTION

1. After unpacking, inspect strainer for damage incurred

during transit. Report any damage to the carrier

immediately. If the strainer is not to be installed

immediately, store indoors in a clean, dry environment.

Replace protective wrap, flange protectors, etc. which may

have been removed during receiving, handling and

inspection.

2. Remove preservative with solvent-dampened cloth.

Exercise care when using solvent and follow solvent

manufacturer’s instructions.

3. Check to be sure the rated pressure and temperature on

the strainer nameplate is not less than the maximum

pressure and temperature of the installation. The rated

pressure shown on the nameplate is the maximum

pressure, including shock, at which the strainer may be

operated.

4. Remove body covers. Check for and remove any foreign or

loose materials that could be carried downstream when

fluid is introduced into the strainer.

5. Be sure shorter baskets are toward the inlet side of the

strainer. Replace strainer cover. Tighten fasteners

uniformly. Baskets are held in place by the pressure of the

cover on the basket handles. If the baskets are loose,

spring the handles to a higher position to insure greater

compression when the cover is seated.

INSTALLATION

CAUTION:

Lift strainer with slings under the

inlet and outlet connections. DO NOT lift the

strainer by the lift eye located on the strainer

cover. The lift eye is used to lift ONLY

the cover.

1.

Position the strainer in the line so that the fluid enters the

connection marked inlet and be sure sufficient headroom

is provided for easy removal of cover and baskets.

2.

Support the strainer in the line as follows. Using the bosses

on the bottom of the strainer, place the unit on concrete

or steel pads. DO NOT support the strainer, or the piping

coming to and from the strainer, by the strainer flanges

and flange bolting.

3.

Connect the strainer to the line. Use the same type flange

faces. For example, DO NOT bolt raised face flanges to iron

INSTALLATION

(

CONTINUED

)

flat face flanges. Iron flanges must be flat face with full-

face gaskets.

4. Cast strainers are subject to face-to-face variations due to

shrinkage and machining tolerances. Prefabricated piping

systems must allow for adjustments to compensate. Be sure

flange gaskets are in place and fasteners are tight.

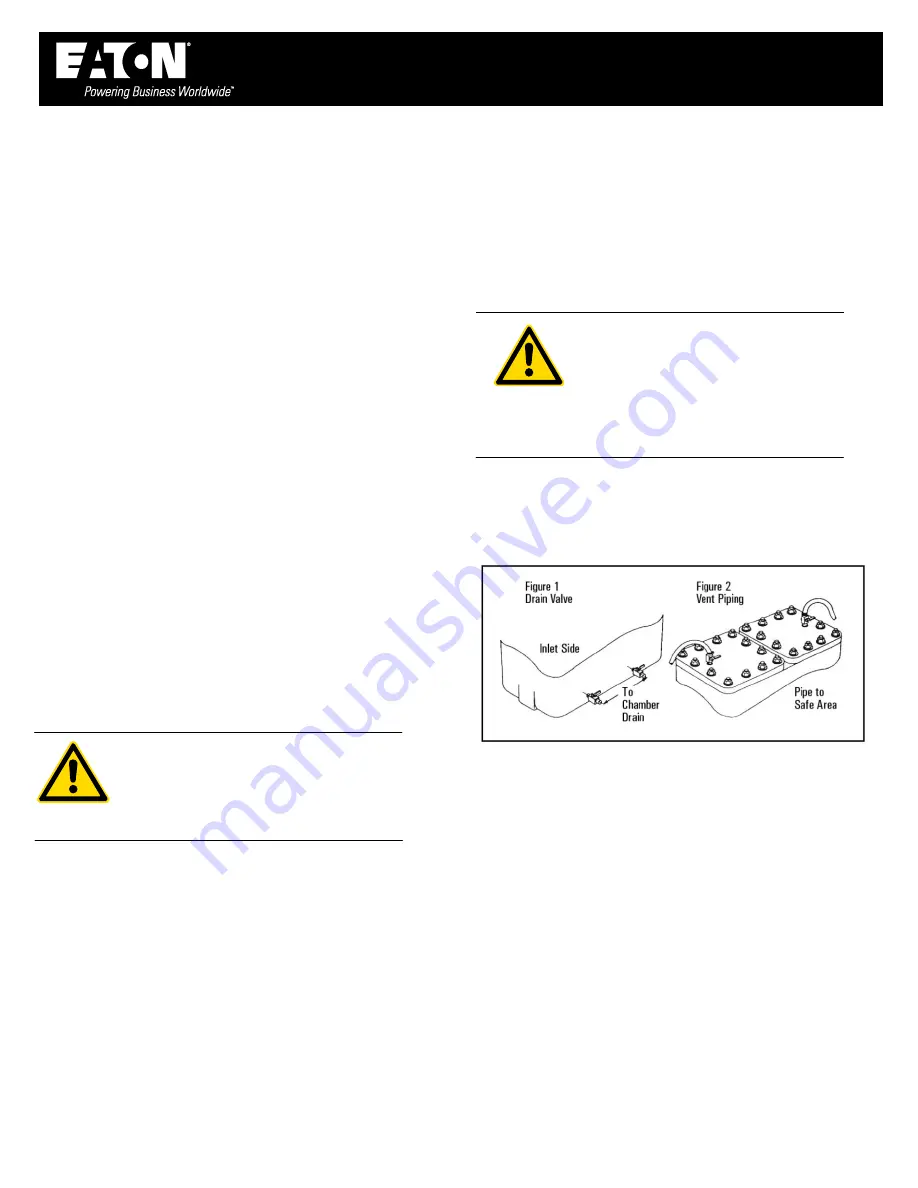

CAUTION:

When strainer handles fluids other

than water and with temperatures in excess

of 120°F, the vent cock must be removed and

the vent piped to a safe discharge point to

protect the operator (see Figure 2). Wear protective clothing

that includes gloves, vests and goggles when handling

dangerous fluids.

5. An external “equalizer line” is provided between the two

basket chambers. Eaton furnishes the ball valve and piping

components. However, on “suction” applications DO NOT

use this arrangement.

RECOMMENDATIONS

1.

Eaton recommends the removal of the drain plugs on the

outlet side of the body and installation of drain valves as

shown in Figure 1.

2.

Pressure gauges, connected a minimum of four pipeline

diameters from the strainer inlet and outlet, are

recommended.

3.

Cleaning frequency can be determined by the pressure drop

across the strainer. Clean the baskets when there is a 5 PSI

increase in pressure loss across the strainer.