To order parts and supplies: 800.345.1178 >> eastwood.com

7

MAINTENANCE

• Add several drops of air tool oil before each use by dropping directly into the air inlet.

• If tool is to be unused for an extended period, add 10 drops of air tool oil directly to the air

inlet, rotate the tool motor by hand several times to distribute the oil throughout the motor and

gearbox then store the tool, handle up.

• Periodically, with the air supply disconnected, check belt condition and Angle Adjusting Screw

tightness.

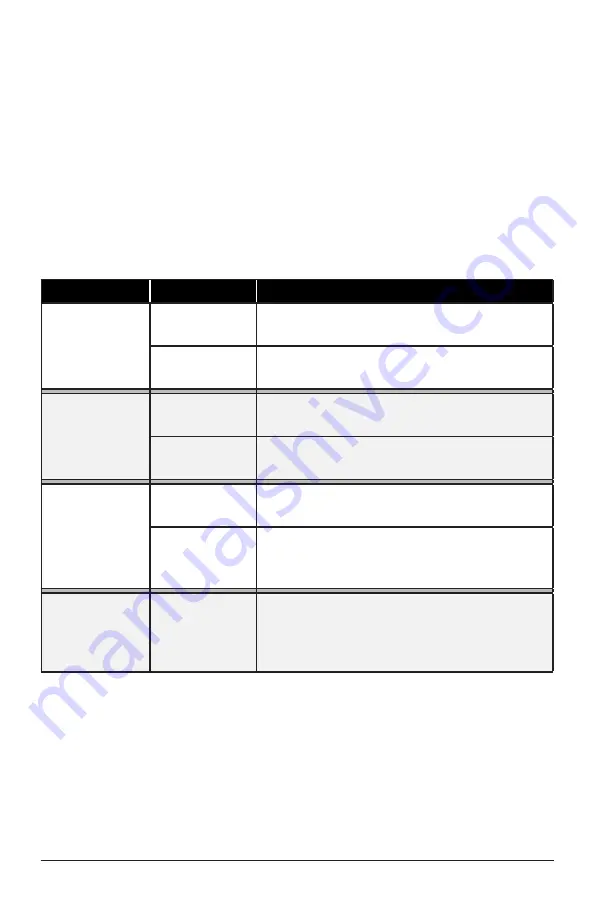

TROUBLESHOOTING

PROBLEM

CAUSE

CORRECTION

Tool Doesn’t

Respond

to Trigger

Depression

Insufficient

Air Supply

Verify sufficient air supply.

Should be 7.1 cfm or more.

Moisture in

Air Line

Check for moisture in air line and tool inlet.

Tool

Performance

is Slow or

Sluggish

Insufficient

Air Supply

Verify sufficient air supply.

Should be 7.1 cfm or more.

Moisture in

Air Line

Check for moisture in air line and tool inlet.

Tool Vibrates

Excessively

During Use

Split or

Torn Belt

STOP USE IMMEDIATELY!

Replace Belt.

Loose Angle

Adjustment

Screw

STOP USE IMMEDIATELY!

Tighten Angle Adjustment Screw

Tool Emits

Excessive

Noise During

Use

Tool Lacks

Lubrication

STOP USE IMMEDIATELY!

Add air tool oil directly to air inlet.