EASTMAN

6

Discard used sharp knives with care.

Whenever servicing machine; check tight-

ness of Plate Bolt Nut before resuming

cutting operation.

ALL SPECIAL TOOLS FOR SHARPENER ADJUSTMENT CAN

BE OBTAINED BY ORDERING TOOL KIT #820C2.

BEVEL-BLOC

Sharpener Shoes

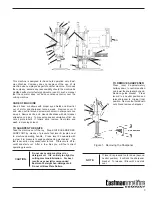

TO CHANGE THE KNIFE

Make sure sharpener is in locked position. Raise pressure foot

to top position by means of pressure foot lever B, located next

to machine operating handle. Lay machine on table as shown.

Press in turning knob A and turn knife to bottom position. Insert

T-handle knife bolt wrench V as shown and loosen knife lockbolt .

Remove knife through bottom of standard W. After removing knife,

clean knife slot in standard with slot cleaner. Insert new knife

in knife slot. Be sure to set knife tightly up against knife lockbolt

and at the same time hold the bottom of the knife against the

back of the slot in the standard when tightening knife lockbolt.

After tightening knife lockbolt, check to see if knife runs freely

in standard by rotating turning knob. Install new sharpener belts

and operate sharpener three or four times before starting to cut.

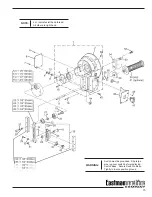

TO ADJUST BEVEL BLOC SHOES

Eastman’s exclusive patented adjustable Bevel-Bloc sharpener

shoes make it possible to grind any desired bevel on the knife

edge. The knife edge bevel on your new machine is factory set

to handle all normal fabrics and should not be changed. Normally

an acceptable bevel is 1/16" wide. If necessary to adjust the

bevel on the knife edge to a different length proceed as follows:

WARNING:

CAUTION:

®

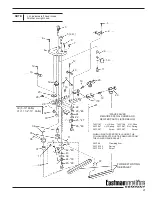

CHANGING THE KNIFE

1. Make sure the sharpener is in the locked position.

2. Raise the pressure foot (X) to the top position using

the pressure foot lever (R), which is located next to the

machine operating handle.

3. Lay the machine on a table, as shown.

4. Press in the turning knob (H on page 4) and turn the

knife to the bottom position.

5. Insert the T-handle knife bolt wrench (Y) and loosen

the knife lockbolt (1).

6. Remove the knife through the bottom of the standard

(Z).

1 knife lockbolt

R pressure foot lever

2 slot cleaner

X pressure foot

E lever

Y T-handle knife bolt wrench

Z standard

7. After removing the knife, clean the knife slot in the

standard with the slot cleaner (2).

8. Insert a new knife in the knife slot. Be sure to set the

knife tightly against the knife lockbolt. Hold the bottom

of the knife against the back of the slot in the standard

and tighten the knife lockbolt.

R

E

Y

1

X

Z

2

Содержание BRUTE 627VS

Страница 11: ...11 ...

Страница 24: ...EASTMAN 24 ...

Страница 25: ...25 ...

Страница 26: ...EASTMAN 26 Notes ...

Страница 27: ...27 Service Record Machine Serial No Machine Voltage Date of Purchase Date Type of Service Performed ...