Page F-16

FRONT SUSPENSION AND STEERING

Repair and Service Manual

Read all of Section B and this section before attempting any procedure. Pay particular attention to all Notices, Cautions, Dangers and Warnings.

ahead position, align the steering wheel on the steering

shaft and slide wheel on shaft. Tighten the steering

wheel nut (6) to 15 - 20 ft. lbs. (20 - 27 Nm) torque.

Inspect the four retaining tabs on the clipboard (5) for

white stress lines (Ref. Fig. 20 on Page F-15). If stress

lines are present, replace clipboard. Install by carefully

pressing, first the top two, then the bottom two retaining

tabs into the matching slots in steering wheel.

Steering Shaft and Column Replacement

Tool List

Qty. Required

Ratchet, 1/2" drive ....................................................... 1

Socket, 3/4", 1/2" drive ................................................ 1

Socket, 13 mm, 3/8" drive ........................................... 1

Ratchet, 3/8" drive ....................................................... 1

Socket, 9/16", 1/2" drive .............................................. 1

Snap ring pliers............................................................ 1

Bearing separator ........................................................ 1

Gear puller................................................................... 1

Arbor press .................................................................. 1

Bearing driver set ........................................................ 1

Torque wrench, 1/2" drive, ft. lbs. ................................ 1

Torque wrench, 3/8" drive, in. lbs. ............................... 1

Wheel bearing grease .............................................. AR

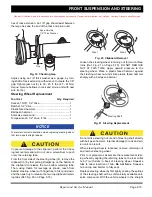

To remove steering shaft (4) (Ref. Fig. 22 on Page F-

16), remove the steering wheel. “Steering Wheel

Replacement” on Page F-15.

Loosen front wheels. Lift and support front of vehicle per

SAFETY section and remove front wheels.

Remove the bolt (1) and washer (2) that secures the

intermediate shaft (3) to the steering shaft (4).

Fig. 22 Steering Shaft and Column

Remove the four bolts (5) and washers (6) that secure

the steering column (7) to the chassis and remove the

column.

Remove large retaining ring (8) on bottom end of column

and pull shaft and bearing (9) out as an assembly. Slide

wave washer (10) out bottom end of steering column

and keep for reuse.

Remove small retaining ring (11) and press bearing from

steering shaft.

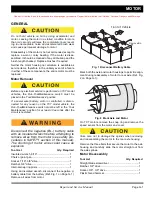

To assemble steering shaft, first press new bearing onto

shaft until it stops against shoulder. Then, with small

retaining ring oriented with arch up, slide ring onto shaft

as far as possible using snap ring pliers (Ref. Fig. 23 on

Page F-16). Use fingers to push retaining ring fully into

groove.

Fig. 23 Small Retaining Ring Orientation

Slide wave washer into base of steering column.

To install steering shaft and bearing assembly, apply

wheel bearing grease to lip of seal in bushing (12) at top

of column and press steering shaft and bearing assem-

bly into column base. Secure with large retaining ring

making sure it is fully seated in groove of column.

Place steering column on vehicle and tighten column

bolts (5) to 29 ft. lbs. (39 Nm) torque.

Tighten bolt (1) securing intermediate shaft to steering

shaft to 156 - 216 in. lbs. (180 - 250 kg cm) torque.

Install front wheel(s) per WHEELS AND TIRES section

and lower vehicle per SAFETY section

Install steering wheel. “Steering Wheel Replacement” on

Page F-15.

4

5

6

12

7

10

9

11

3

8

1

2

Install with arch

up as shown

Small

Retaining

Ring

Groove

Bearing

Steering

Shaft