ELECTRONIC SPEED CONTROL (36V)

Page F-13

Repair and Service Manual

Read all of Section B and this section before attempting any procedure. Pay particular attention to all Notes, Cautions and Warnings

INDUCTIVE THROTTLE SENSOR (ITS)

TESTING AND REPLACEMENT

Tool List

Qty. Required

Phillips screwdriver ..................................................... 1

Wrench, 7/16" ............................................................. 1

Nut driver, 7/16" .......................................................... 1

Drill bit, 17/64"............................................................. 1

DVOM ......................................................................... 1

Raise the rear wheels of the vehicle and support the

vehicle on jack stands (Refer to Lifting Procedure in Sec-

tion ‘B’ Safety). Test the vehicle stability before proceed-

ing.

Remove the driver’s side rocker panel insert and pull the

floormat forward to expose the metal cover to the pedal

box (Ref Fig. 15 on page F-13).

Remove the cover and remove the four screws securing

the plastic cover to the pedal box (Ref Fig. 16 on page F-

13).

Set the parking ‘PARK’ brake. With the DVOM set to

volts, probe the white wire at the ITS with the positive

probe and attach the negative probe to the B- at battery.

Place the direction selector in ‘F’ and turn the key switch

to ‘ON’. Depress the accelerator pedal. As the solenoid

clicks the meter should read between 0.4 - 0.6 volts. The

meter should read 1.5 - 1.7 volts at full pedal (Ref Fig. 18

on page F-15). If the reading is out of specification, the

ITS sensor must be replaced.

The ‘ITS’ attaches to the plastic pedal

box using two plastic studs and two

speed nuts. Use care not to overtighten the nuts which could

strip the plastic studs while tightening the nuts enough to pre-

vent movement of the ‘ITS’.

Carefully remove the two wires that attach to the ITS and

carefully remove the nuts securing the ITS to the plastic

pedal box studs.

Install a new ITS being careful to align the ITS and not to

overtighten the retaining nuts. Attach the wiring.

With the accelerator pedal in the full up position, insert a

17/64" drill bit between the plunger and the face of the

ITS. The drill bit should be used to verify and adjust the

distance between the face of the ITS and the face of the

plunger (Ref Fig. 17 on page F-14). If the plunger

needs adjustment, loosen the lock nut and rotate the

plunger until the desired dimension is achieved. Firmly

tighten the jam nut.

Replace the plastic cover and press it firmly into place

before tightening the cover screws.

Replace the metal cover, floormat and rocker panel

insert.

Fig. 15 Access to Pedal Box

Rocker Panel

Floor Mat

Access Cover

Pedal Box

PAR

K

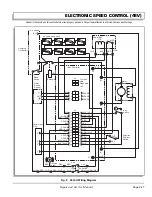

Fig. 16 ITS and Plunger

Micro Switch

'ITS'

Connector

Plunger

Micro Switch

Adjusting Cam

Lock Nut

Содержание MPT 800

Страница 6: ...Page iv Repair and Service Manual TABLE OF CONTENTS Notes...

Страница 10: ...Repair and Service Manual SAFETY INFORMATION Page viii Notes...

Страница 12: ...GENERAL INFORMATION ROUTINE MAINTENANCE Page A ii Repair and Service Manual Notes...

Страница 20: ...SAFETY Page B ii Repair and Service Manual Notes...

Страница 32: ...BODY Page C ii Repair and Service Manual Notes...

Страница 42: ...WHEELS AND TIRES Page D ii Repair and Service Manual Notes...

Страница 46: ...FRONT SUSPENSION AND STEERING Page E ii Repair and Service Manual Notes...

Страница 104: ...MOTOR Page G ii Repair and Service Manual Notes...

Страница 112: ...BATTERIES AND CHARGING Page H ii Repair and Service Manual Notes...

Страница 122: ...ELECTRICAL SYSTEM Page J ii Repair and Service Manual Notes...

Страница 158: ...BATTERY CHARGER Page L ii Repair and Service Manual Notes...

Страница 166: ...REAR SUSPENSION Page M ii Repair and Service Manual Notes...

Страница 170: ...REAR AXLE Page N ii Repair and Service Manual Notes...

Страница 176: ...WEATHER PROTECTION Page P ii Repair and Service Manual Notes...

Страница 182: ...PAINT Page Q ii Repair and Service Manual Notes...

Страница 186: ...TROUBLESHOOTING Page R ii Repair and Service Manual Notes...

Страница 192: ...LIGHTNING PROTECTION AND GROUNDING Page S ii Repair and Service Manual Notes...

Страница 198: ...GENERAL SPECIFICATIONS Page T ii Repair and Service Manual Notes...

Страница 210: ...Page T 12 Repair and Service Manual GENERAL SPECIFICATIONS...