MAGNET COIL REPLACEMENT

(See Figures 1, 3 & 4)

Remove magnet assembly as outlined under FRICTION DISC

REPLACEMENT.

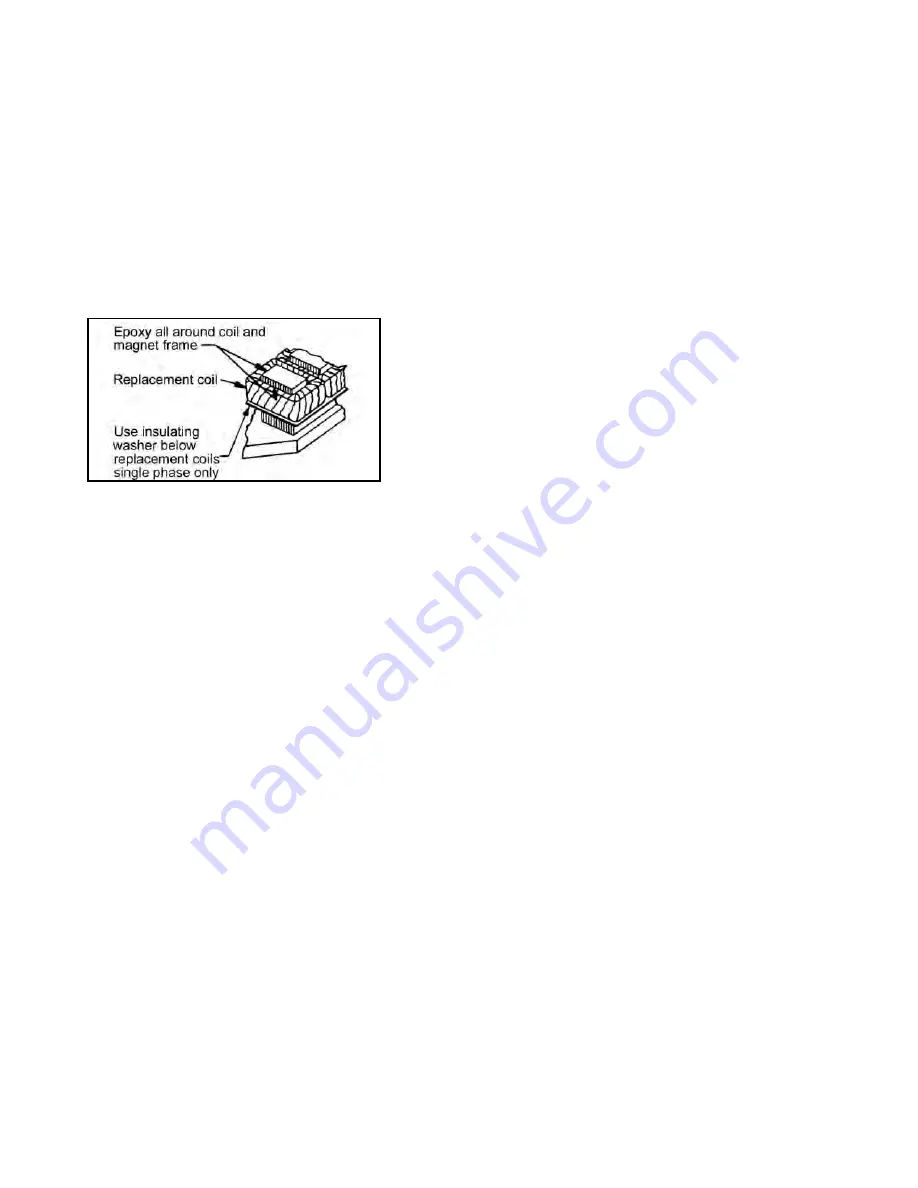

Coils (6b) are held in place with epoxy cement. Force coil off

magnet mounting plate and remove excess epoxy from all surfaces.

Replacement coils should be held in place with new epoxy cement.

The epoxy cement should be heat resistant and shock resistant.

Place an insulating washer (6c) below the coils. Order insulating wash-

ers when ordering coils. An insulating washer can be cut to

suit when replacing only one coil on a multiple coil assembly.

When installing coils, it is very important to follow EXACTLY the

sequence of black and light colored leads as shown in wiring

diagram (Figure 1). The brake will not operate properly unless coils

are all in the correct position.

Reassemble all parts in reverse order.

TROUBLE SHOOTING

A. IF BRAKE DOES NOT RELEASE:

1.

Check brake visually for broken or damaged parts.

2.

Check for broken leadwire or bad electrical connection.

3.

Check for correct voltage. Line voltage must correspond to

the voltage for which the brake coils are connected. If the

line voltage is more than 10% below the voltage for which

the brake coils are connected, the magnet will not pull in,

causing the coils to burn out within minutes. If the line voltage

is more than 10% above the voltage for which the brake coils

are connected, the coils will overheat and burn out.

4.

Check for burned-out coils (coils may be charred or burned).

5.

Check for excessive magnet gap. (See WEAR ADJUST

MENT.)

6.

Check for failure or power supply to brake.

B. IF BRAKE DOES NOT STOP:

1.

Check brake visually for broken or damaged parts.

2.

Make certain hub has not shifted position on the motor shaft

and that all rotating discs are fully engaged on the hub.

3.

Check that the manual release is in the normal position.

4.

Check disc wear. (See WEAR ADJUSTMENT.)

C. IF BRAKE CHATTERS OR HUMS:

1.

See that magnet faces are clean. To remove dirt, insert a

clean sheet of paper between magnet faces and energize

brake. Move paper around between faces to dislodge dirt,

then remove paper.

2.

Check for low voltage. Magnet will not pull in, and coils will

burn out if line voltage is beyond 10% below the voltage the

brake coils are connected for.

3.

See that magnet faces are parallel within tolerance.

Readjust magnet gap to “D” min.

(See WEAR ADJUSTMENT.)

4.

Check if shading coil (6d) is cracked, broken or out of

position (single phase only).

D. IF MANUAL RELEASE DOES NOT WORK:

1.

Check for broken or damaged parts.

2.

Check return spring (13). Brake will not reset automatically if

this spring is broken.

3.

Check quantity of shim washers (15) under release stop

screws. (See Manual Release Assembly under

“FRICTION DISC REPACEMENT”.)

Figure 3. Fastening of Replacement Magnet Coils

SPECIFICATIONS

MOTOR FRAMES -

182TC, 184TC, 213TC, 215TC, 254TC, 256TC.

ENCLOSURES

- NEMA 2

(material: aluminum and cast iron)

DUTY

- Rated for continuous duty.

VOLTAGES

- All standard NEMA voltages and frequencies available.

Other voltages and frequencies are optional.

MOUNTING

- Direct to NEMA “C” face, with one additional “C” face for

mounting of equipemnt to brake. Some standard motor shafts may

need modification, see Table 1.

Horizontal or vertical mounting with modifications.

ORDERING INFORMATION

The following data should be furnished with your order for:

REPLACEMENT PARTS

Brake Model Number

Part Number from Tables

Part Description from Tables

Hub Bore & Keyway. Shaft Extension Diameter & Keyway.

For electrical parts specify voltage, phase, and frequency.

REPLACEMENT BRAKE

Model Number

Voltage, Phase & Frequency

Hub Bore & Keyway Dimensions. Shaft Extension Diameter & Keyway.

Mounting - Horizontal or Vertical. (If vertical, specify whether above or

below motor.

3