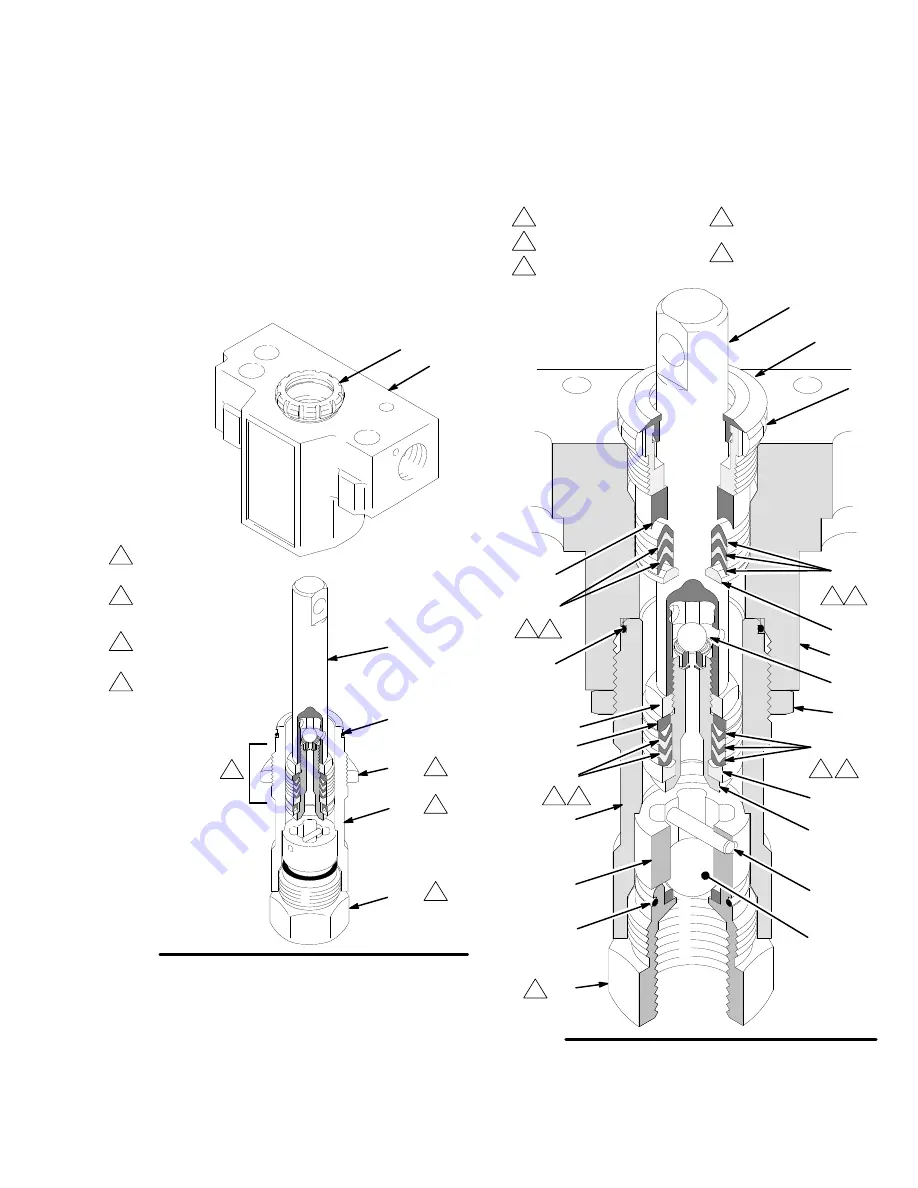

Displacement Pump Repair

11. Place a new o-ring (116*) firmly in the cylinder

groove. See Fig. 22.

12. Coat the piston rod and packings with oil. Carefully

slide the assembly into the top of the cylinder

(115). See Fig. 22.

13. Put the manifold upside down in a vise. Fully

thread the jam nut (117) onto the cylinder (115).

Guide the rod/cylinder assembly down through the

manifold (101). Screw the cylinder (115) into the

manifold. See Fig. 22.

Fig. 22

1

3

2

01072A

102

101

116*

117

115

118

107

Torque jam nut (117)

to 73 ft–lb (98 N.m)

Torque cylinder (115)

into manifold (101) to

53 ft–lb (71 N.m)

Torque intake valve (116)

into cylinder (115) to

53 ft–lb (71 N.m)

1

2

3

4

Piston assembly

4

14. Place the ball guide (120), stop pin (122) and ball

(121*) in the cylinder (115). Screw the intake valve

into the cylinder and torque to 53 ft-lb

(71 N.m). This will also properly torque the cylinder

into the manifold. See Fig. 23.

15. Torque the cylinder jam nut (117) to 73 ft-lb

(98 N.m). See Fig. 22.

16. Install the pump. See page 22.

Fig. 23

1

3

4

2

01073

107

123

102

104*

106*

101

117

112*

114*

108*

122*

121*

109*

*103

*105

*116

111

*113

115

120

*119

118

Leather packings

Poly packings

Lips of V–packings

must face down

Lips of V–packings

must face up

5

Torque to 53 ft–lb

(71 N.m)

1

3

2

3

2

4

1

4

5

110