- 21 -

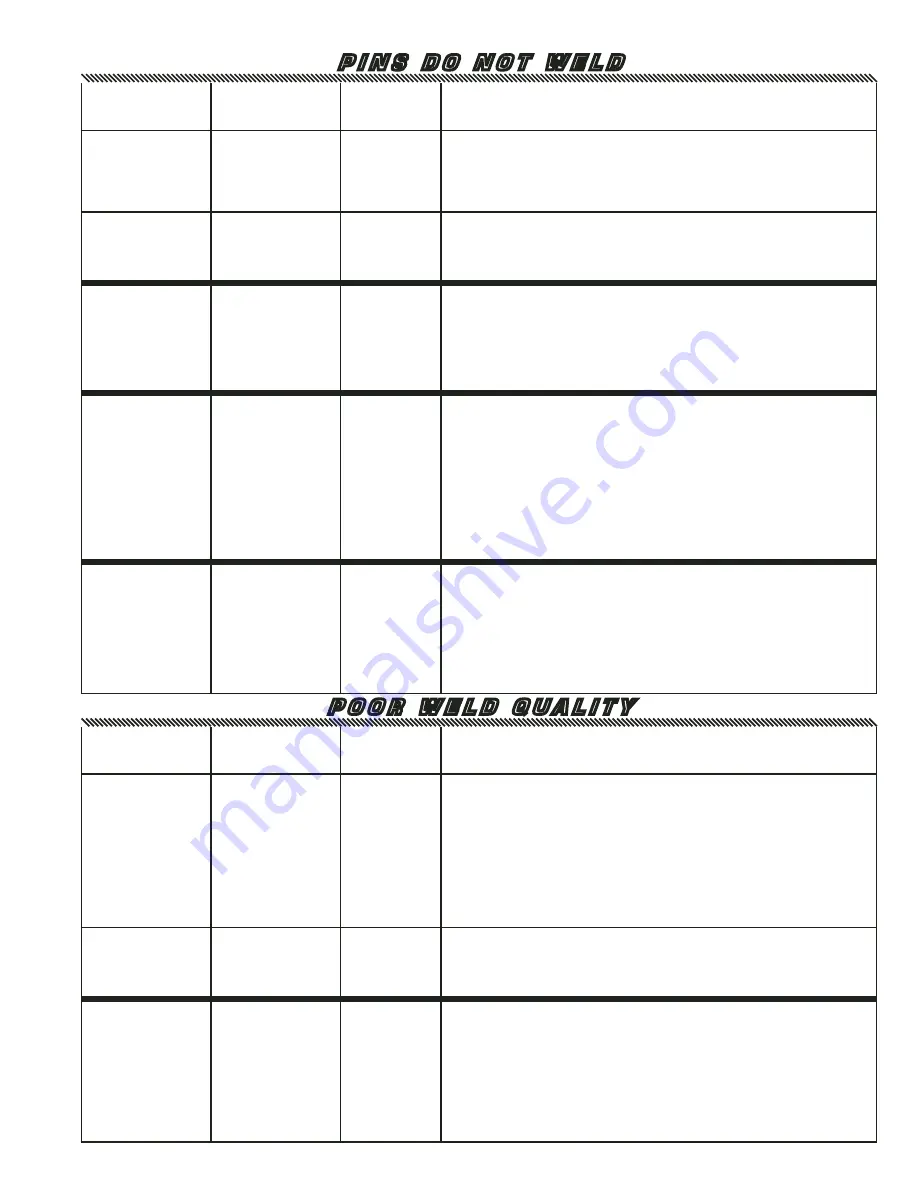

P I N S D O N O T W E L D

P O O R W E L D Q U A L I T Y

SYMPTOM

CORRECT

FUNCTION

INDICATOR

POSSIBLE

PROBLEM

ACTION

All indicators are

functioning

except

Weld signal, Weld

#1 and Weld #2

Weld signal indica-

tor goes on and

off with every

cycle

(A) Short cycle

relay.

(A) The Short cycle relay controls the voltage that turns on the Solid-

state relays that turn on the Weld transformer. To test this Short

cycle relay circuit check the voltage (24VAC+/-) at terminals #18 and

#21. Terminals #18 and #21 should go from 0 to 24VAC and back

to 0 on every cycle. If this voltage reading is incorrect replace Short

cycle relay.

(B) Pressure

switch.

(Mach Two

models

only)

(B) To test the pressure switch place a jumper between terminals #37

and #38. If the machine welds with jumper in place replace Pressure

switch.

All i

ndicators are

functioning except

Weld #1 and

Weld #2

Weld relay #1 or

Weld relay #2

indicator should

correspond with

Weld signal

indicator.

Goes on and off

with every cycle

Head test

switch.

The head test switch is single-pole, double-throw and center off switch.

This switch delegates which Solid State Relay controls the Weld

transformer.

To test this switch check for continuity at the switch.

All indicators are

Functioning.

Welding indicator

on the frame is

not functioning.

This indicator

shows when

there is voltage

(/-)

present at

the Primary

of the Weld

transformer.

All lights flash in

sequence

Solid State

Relay

The Solid State Relay controls the voltage to the Primary of the Weld

transformer. To check these Solid State Relays test for voltage

(24VAC+/_) at terminals A1 and A2 on the relay. Terminals A1 and

A2 should go from 0 to 24VAC and back to 0 on every cycle. If this

voltage reading does not correspond check the switch position. If this

voltage reading is correct now test the voltage (208-230 VAC+/-) at

the terminals L1 and T1. Terminals L1 and T1 should go from (208-230

VAC+/-) to 0 and back to (208-230 VAC+/-) with every cycle. If this

voltage is incorrect replace Solid State Relay.

All indicators are

functioning in-

cluding the Weld

indicator on the

frame

All lights flash in

sequence

Weld trans-

former.

To test the Primary of the transformer check the voltage at the terminals

L1 and T1 on the Solid State Relays. They should go from (208-230

VAC+/-) to 0 and back to (208-230 VAC+/-) every time the machine

cycles. Now test the secondary output voltage. Place meter leads on

copper bars coming out of the transformer(s) and test the voltage

every time the machine is cycled. The Mach 1 Transformers should

read approximately 5VAC. (2.5 VAC x 2 =5VAC) The Mach 2 should read

approximately 10VAC. (maybe 5VAC if on center tap) If the secondary

voltage reading is incorrect replace the transformer. (Turn the Weld

time to the highest setting when performing this test.)

SYMPTOM

CORRECT

FUNCTION

INDICATOR

POSSIBLE

PROBLEM

ACTION

Dwell delay

indicator is not

functioning

Dwell delay indicator

comes on when

the Weld timer

indicator goes off

and then goes off

when the Dwell

solenoid indicator

goes off.

(A) Short cycle

relay or

First pulse

relay

(A) The Dwell delay timer keeps the Dwell circuit on 150ms longer than

the Weld timer circuit. To check the Dwell delay timer test for voltage

(24VAC+/-) at terminal #11 and #12. The voltage on terminals #11

and #12 should go from 24VAC to 0 and back to 24VAC with every

machine cycle. If this voltage reading is correct proceed to step (B).

If this voltage reading is incorrect check the Short cycle relay at the

terminals TB4 (NC) and #11. This voltage reading should go from 24VAC

to 0 and back to 24VAC on every machine cycle. If this voltage reading

is incorrect replace the Short cycle relay. If this voltage reading is

correct and the voltage reading at terminals #11 and #12 are still

incorrect replace the First pulse relay

.

(B) Dwell delay

timer

(B) If procedures (A) test correctly now check the voltage (24VAC+/-) at

the terminals #9 and #12. The voltage at the terminals #9 and #12

should go from 0 to 24VAC and back to 0 on every machine cycle. If this

voltage reading is incorrect replace the Dwell delay timer.

All indicators are

functioning

All lights flash in

sequence

(A) Weld cable.

(B) Upper and

Lower

welding tips.

(C) Upper tip

retainer.

(D) Weld cable

retainer.

(F) Power

supply bar

Any connection from the Secondary of the Transformer to the Weld tips

can contribute to a poor weld quality. All the connections should be

Clean, Bright and Tight.

The Weld cable from use can also start

breaking down. Always inspect the Weld cable, transformer secondary

connections and Weld tips for they are the most common causes for

a poor weld quality.