Installation, operation and maintenance instructions - DualSun XXXM

–

60

–

3BBP

V1.2

–

March 2020

Page

20

sur

41

b.

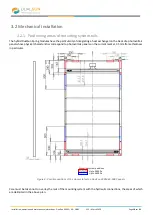

Checking the roof layout

The positioning of the first module depends on the corrugation crest routing detailed above. Then check that each

DualSun fitting is correctly positioned in the corrugation recess, according to the width of the inter-panel clamps,

respecting the minimum distances for the routing of the hydraulic links through the corrugation crests.

Portrait layout

Figure 16 : Portrait layout

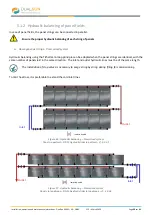

Landscape layout

Figure 17 : Landscape layout

Sheet metal roof with 333 mm corrugation length : Select an inter-panel distance of 16.67 mm if possible

and place the end of the module 325 mm from the centre of the corrugation crest. The position of the

modules will thus be identical in relation to the corrugation crests over the entire layout.

c.

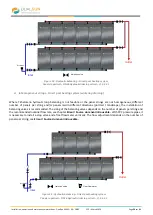

Checking the routing of the hydraulic links

Routing perpendicular to the corrugations

–

Configurations 3.2.3.1 and 3.2.3.3

The previous points allow to check the routing of the hoses perpendicular to the corrugations according to the

characteristics of the DN15 or DN26 hoses, to the height of elevation of the modules and to the positioning of the

hydraulic links in relation to the corrugations.

Routing parallel to the corrugations

–

Configurations 3.2.3.2 and 3.2.3.4

Routing through rails may occur according to the mounting system. In this case it is possible to run the hydraulic links

beneath or from the side of the rails.

It is necessary to ensure that :

-

The height between the rails and the roof surface is greater than the external diameter of the flexible hoses,

see table 1 above.

-

The bending radius of the flexible hose is greater than the minimum bending radius to avoid the rails, see

table 1 above.

-

The rails are at a sufficient distance from the hydraulic fittings to comply with the minimum bending radii of

the flexible hoses within the permissible fixing areas, see 3.2.1.