Access XL 220 Volt Instructions by Draper

page 3 of 5

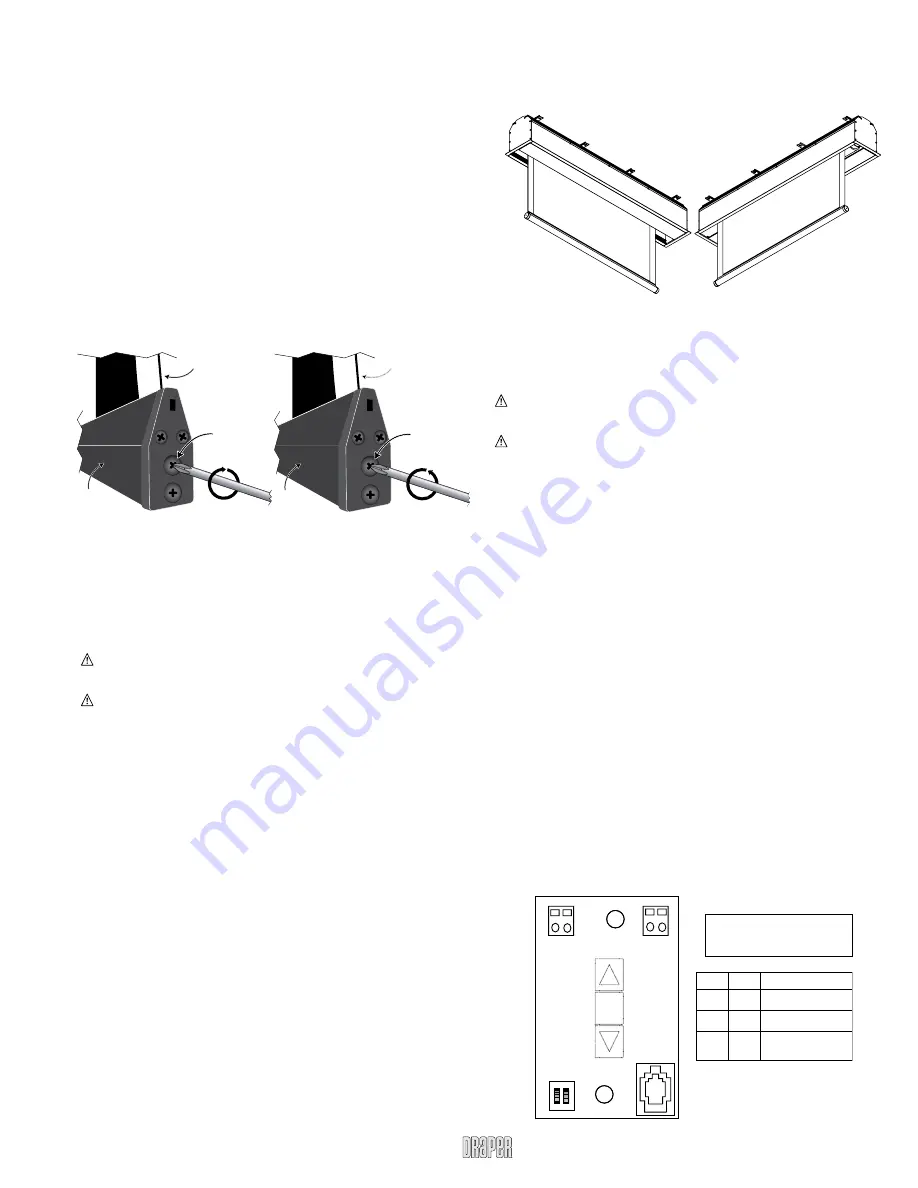

Limit Adjustments (Standard Motor)

Please Note: Screen limits are factory set for optimum performance of

the screen. A procedure is outlined below for minor tweaks, but any

adjustment of these limits may negatively affect the flatness of the

screen surface and could also void the warranty. Please check with

Draper prior to resetting screen limits.

CAUTION: Always be prepared to shut screen off manually when new

adjustment is being tested. Screen may be severely damaged if viewing

surface is allowed to run too far up or too far down.

CAUTION: Be sure all switches are in “off” position before adjusting

limit switches.

The motor limit screws are normally located on the audience left of screen

roller.

**Please Note: If the Access XL is “Right Hand Motor”, WHITE/DOWN and

YELLOW/UP limit screws are reversed. See graphic below.

"Down" Limit Adjustment

To Reduce Screen Drop

1

Raise screen surface about 30cm above desired setting and turn off.

2

Turn the WHITE/DOWN limit screw clockwise (three screw turns = ½ roller

revolution).

3

Test by running screen down and repeat steps 1 and 2 until desired position

is reached.

To Increase Screen Drop

1

Run screen to the down limit.

2

With the down switch on, turn WHITE/DOWN limit screw counterclockwise

(3 turns of screw equals ½ roller revolution) to increase drop. Screen will

drop automatically for each turn.

3

Test by running screen up about 30cm and back down to new down limit.

4

Repeat steps 2 and 3 until desired position is reached.

"Up" Limit Adjustment

Screen is Running Too Far Up

1

Lower screen surface about 1' below desired setting and turn off.

2

Turn YELLOW/UP limit screw clockwise (3 screw turns = ½ roller revolution).

3

Test by running screen up.

4

Repeat steps 1 through 3 until desired position is reached.

Screen Needs to Run Up More

1

Run screen down about 30cm and turn off.

2

With the up switch on, turn the YELLOW/UP limit screw counterclockwise (3

turns of screw equals ½ roller revolution). Screen will drop automatically for

each turn.

www.draperinc.com

(765) 987-7999

available with an override switch (VIC–OS), permitting independent operation.

VIC–OS not available with factory installed VIC220 & VIC12.

KEY OPERATED SWITCHING

—(Not CE Approved) Two kinds of key-

operated switches are optionally available with this unit.

1

The key-operated

power supply switch controls power to the screen and switches. When it is

“off”, the switches will not operate screen. Key may be removed from the

switch in either “on” or “off” position.

2

A three-position key switch permits the

screen to be operated directly by key. In this case, the screen’s operator must

always have a key.

RS232/ETHERNET—

Serial communication and network communication

optionally available with wall switches, RF or IR remote.

Limit Adjustments (Built-in Low Voltage Motors)

Please Note: Screen limits are factory set for optimum performance of

the screen. A procedure is outlined below for minor tweaks, but any

adjustment of these limits may negatively affect the flatness of the

screen surface and could also void the warranty. Please check with

Draper prior to resetting screen limits.

CAUTION: Always be prepared to shut screen off manually when new

adjustment is being tested. Screen may be severely damaged if viewing

surface is allowed to run too far up or too far down.

CAUTION: Be sure all switches are in “off” position before adjusting

limit switches.

Please note: When ordering a motor with built-in Low Voltage Control-

ler, if the case ships separate from the "guts," the case includes the 25'

cable and special low voltage switch.

1

Connect the ILT switch to the motor via the terminal blocks, or via the

modular port using four conductor modular cable. When using modular

cable, the cable connectors MUST NOT be crimped in reverse, as with

standard telephone cable. (For Dry Contacts Wiring Diagram, see page 4.)

2

Set the slide switch to the lower position. Press and hold the DOWN button

on the switch to move the viewing surface to the desired lower limit. If the

screen moves in the opposite direction, release the DOWN button and

press and hold down the STOP button for four seconds. This will reverse

the operation of the UP and DOWN switches.

3

Move slider switch into center position. Wait a couple of seconds.

Please Note: If you move the slider switch from down to up in one mo-

tion it sets the two limits in the same position.

4

Set the slide switch to the higher position. Move the viewing surface to the

desired upper limit by pressing and holding the UP button on the wall

switch.

5

Return the slide switch to the center position to return to normal operation.

6

To set the viewing surface to an alternate format position, move the viewing

surface to the desired position and press the STOP button. Press and hold

the STOP button for at least three seconds to record the position.

Please Note:

Pressing and releasing the UP button on the switch will move

the screen to its upper limit. Pressing and releasing the DOWN button will

move the screen to its lower limit.

While the motor is in motion, pressing the STOP button for less than two

seconds will stop the viewing surface at its present position.

Once the motor is stopped, pressing the STOP button will move the view-

ing surface to its alternate format position.

Pressing and holding the STOP button, when the motor is at rest or in mo-

tion, for at least three seconds will record a new alternate format position.

S

S

T

T

O

O

P

P

To

Motor

Back View

SW1

SW2

FUNCTION

ON

ON

OFF

OFF

OFF

OFF

Set LOWER limit

Set UPPER limit

Record Position/

Normal Operation

OFF

1 2

U

p

D

o

w

n

G

r

o

u

n

d

+

5V

S

S

T

T

O

O

P

P

To

Motor

Back View

SW1

SW2

FUNCTION

ON

ON

OFF

OFF

OFF

OFF

Set LOWER limit

Set UPPER limit

Record Position/

Normal Operation

OFF

1 2

U

p

D

o

w

n

G

r

o

u

n

d

+

5V

Left Hand

Motor Location

Right Hand

Motor Location

(Fabric from

back of roller)

(Fabric over

front of roller)

Audience

Side

Audience

Side

Please Note: 5V DC must be

connected to be able to set

limits using the wall switch.

Tab-Tension Adjustment Procedure for AccessXL

Draper’s Tab-Tensioning System is factory-set, and under normal circumstances

will not require field adjustment. If, however, you notice wrinkles, waves or other

indications that the tensioning cables need to be adjusted, follow the procedure below.

1

Determine which side requires adjustment.

2

Secure dowel with one hand.

3

Using Phillips-head screwdriver, depress spring-loaded adjustment screw

and slowly turn

CLOCKWISE TO INCREASE

tension, or

COUNTER-CLOCKWISE TO RELEASE

tension. The screw adjusts in

60° turn increments. Adjust only

one increment

(60° turn) at a time

.

4

If problem is not corrected, leave screen in position for 24 hours to allow

surface material to stretch into position.

5

If problem still is not corrected, repeat steps 2 and 3.

ADJUSTMENT

SCREW

TENSIONING

CABLE

DOWEL

TO

RE

LEASE TEN

SIO

N

T

U

R

N

C

OU

NTER-CLO

CK

W

IS

E

CLOCKW

IS

E

ADJUSTMENT

SCREW

TENSIONING

CABLE

DOWEL

TO

IN

CREASE TEN

SIO

N

T

U

R

N

3

Repeat steps 1 and 2 until desired position is reached.

CAUTION: Do NOT allow the dowel to wrap up over the roller when the

screen is running up! This could damage the screen.