TL 1128 (TOP HOLES)

Issued August 2016

Revision No: 006

Printed in U.S.A.

Copyright 2016, Bayne Premium Lift Systems

Diverter Valve Information

14

OPERATION AND INSTALLATION INFORMATION

WI-0026

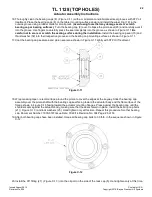

The Bayne diverter valve establishes priority flow to the lifter circuit “P1” and “P2” ports and bypasses oil to the “OUT” port,

which typically supplies flow to the remainder of the truck’s hydraulic circuit. This bypass occurs only after the lifter circuit is

satisfied. The priority flow is controlled by the flow regulator cartridge (FR1) (and FR2 in dual applications) in combination

with the differential pressure sensing valve (DPS). This allows the valve to maintain constant flow regardless of changes in

load pressure or volume flow rate. Since both the lifter circuit and bypass flow can be utilized in the operation of the truck

regardless of which pressure is greater, a single pump can be used to supply two circuits or operations.

The lifter circuit flow is regulated and maintained by the flow regulator cartridge (FR1) (and FR2 in dual applications). The

differential pressure sensing valve (DPS), rated for 75 gpm of flow and 3000 psi of pressure, is operated by an internal

spring and dampening orifice (OR) which establishes a pressure drop across the block sufficient to ensure the correct

operation of the flow regulator (FR1). For a dual diverter valve, a second flow regulator cartridge (FR2) is installed in the

“FR2” cavity and a shuttle valve (DSV) is installed in place of the SAE plug in the “DSV” cavity. Once the pressure drop is

established, a precision metered flow is provided to the tipper circuit(s) with additional flow being bypassed to the “OUT”

port.

The operation of the diverter valve does not require the use of a tank line to be run to the “T” port. However, the efficiency

of the block will be significantly increased if a tank line is installed. The logic circuit of the block will manage the flow of oil

returning from the tipper circuit to ensure optimum performance. This is primarily controlled with the sequence valve (PSV)

which is factory set and should not be adjusted. All oil returning from the tipper circuit will normally be regenerated into the

outgoing flow to ensure that the downstream functions are not slowed in any way. When the downstream backpressure

rises to a predetermined pressure, the block will redirect the flow to the “T” port to increase the overall efficiency of the

block and reduce the pressure drop through the block. If the “T” port is connected to a tank line, the oil will be dumped

through the block at a lower pressure. This allows downstream functions to operate at the highest possible pressure when

pressure is being required. If the “T” port is blocked, the oil will be redirected back into the outgoing flow through the check

valve (CV).

A relief circuit for the tipper function is controlled by a relief valve (RV), which is preset to 2300 psi. This can be adjusted to

limit pressure to the tipper(s). This relief valve is more efficient than the relief in the hand valve and will operate with less

noise. It is recommended that it be adjusted to relieve before the hand valve relief. It may also be used to limit the weight

the lifter can dump. This may be beneficial in avoiding damage to cans resulting from overloading. This should be the only

adjustment that the block may require. Any other adjustments should only be made after close consultation with Bayne’s

Engineering Department to ensure proper operation.

Содержание Environmental Solutions BAYNE TL 1128

Страница 4: ...INTENTIONALLY LEFT BLANK TL 1128 TOP HOLES ...

Страница 54: ...INTENTIONALLY LEFT BLANK 50 TL 1128 TOP HOLES ...