rev:12.07.17

3.5.

Summer mode

During unit's work heat recovery is only needed to temperature of around 18

°

C

. Cold recovery is neecessary

in ventilated rooms if temperature is above 26

°

C

.

When outter temperature is between 15-26

°

C

it is required to use by-pass, which results in ommision of warming the air. For this purpose Optimal 400 by-

pass/600 b-pass ar equipped with automatic by-pass.

The moment when by-pass is opened hear exchange does not take place. By-pass is used for cooling

ventilated rooms with the use of cool air for example from GWC.

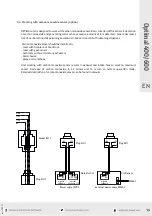

Switch, presented on the picture below in position By-Pass Manual means opening the actuator.

It closes when outter temperature falls below 10

℃

. Switching to By-Pass Auto means automated work

of actuator.

Optimal 400/600

9.

By-pass location

10.

1- Bypass Auto

2 - Bypass Manual

3 -

Actuator

4 -

Carbon monoxide sensor

Bypass

EN