Operation & Maintenance Manual

Starting

Do not use ether or any other starting fluid. Starting fluids can cause

An explosion, fire, and severe engine damage. The engine is equipped

with an electric heater starting aid.

1. Press the main power button.

2. When the wait to start message disappears, press and release green start button.

3. Engine will crank until engine starts or engine starting time limit is reached. The first

light on the start button will illuminate.

4. If engine fails to start, press main power button to remove power from engine. Repeat

steps 1-3.

5. When engine starts, the first two lights on the start button will illuminate.

6.

Wait for engine temperature to reach 150° F (65° C). Press service air button. The

third light on the start button will illuminate.

To ensure an adequate flow of oil to the Airend, never allow the discharge

pressure to fall below 50 psi.

Normal Operation

The operator may observe and monitor operating parameters using the Mini-Port and

gauges. In the event the compressor controller detects a parameter outside normal operating

limits, the compressor will alert and/or shutdown, and display a diagnostic code.

In the event the compressor controller detects a parameter at a dangerously high or low level,

the compressor will be automatically shut down with the cause of the shutdown shown on

the Mini-Port.

Two Pressure Modes of Operation

The Compressor is capable of operating at Two Pressure Modes:

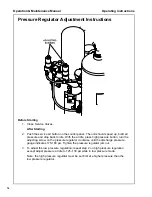

1. The Low Pressure Mode is activated by pressing the Lo Pressure Button. In this

mode, the compressor will regulate according to the air demand, between 0 and 250

cfm at 100 psi regulated set pressure. The regulated set pressure of this mode can

be changed (see Pressure Regulating Adjusting Instructions) from 80-100 psi.

2. The High Pressure Mode is activated by pressing the Hi Pressure Button. In High

Pressure Mode, the compressor will regulate according to air demand, between 0 and

52

Содержание Infracore HP210WDO-T4F

Страница 2: ......

Страница 3: ...iii...

Страница 4: ......

Страница 8: ...8...

Страница 9: ...Foreword 9...

Страница 12: ...12...

Страница 13: ...Drawbar Instructions 13...

Страница 16: ...16...

Страница 17: ...Safety 17...

Страница 25: ...Safety Operation Maintenance Manual 25...

Страница 26: ...26...

Страница 27: ...Noise Emission 27...

Страница 32: ...32...

Страница 33: ...General Data 33...

Страница 36: ...36...

Страница 37: ...Operating Instructions 37...

Страница 55: ...Engine Operation 55...

Страница 86: ...86...

Страница 87: ...Lubrication 87...

Страница 90: ...90...

Страница 91: ...Maintenance 91...

Страница 99: ...99...

Страница 100: ...Operation Maintenance Manual Maintenance Preventive Maintenance Schedule Preventive Maintenance Schedule Front 100...

Страница 101: ...Maintenance Operation Maintenance Manual Preventive Maintenance Schedule Back 101...

Страница 102: ...102...

Страница 103: ...Troubleshooting 103...

Страница 114: ...114...

Страница 115: ...Appendix A 115...

Страница 116: ...Operation Maintenance Manual Appendix A Warranty 116...

Страница 117: ...Appendix A Operation Maintenance Manual 117...

Страница 118: ...Operation Maintenance Manual Appendix A 118...

Страница 120: ......

Страница 121: ......