4-85

Inspection, Maintenance and Adjustment

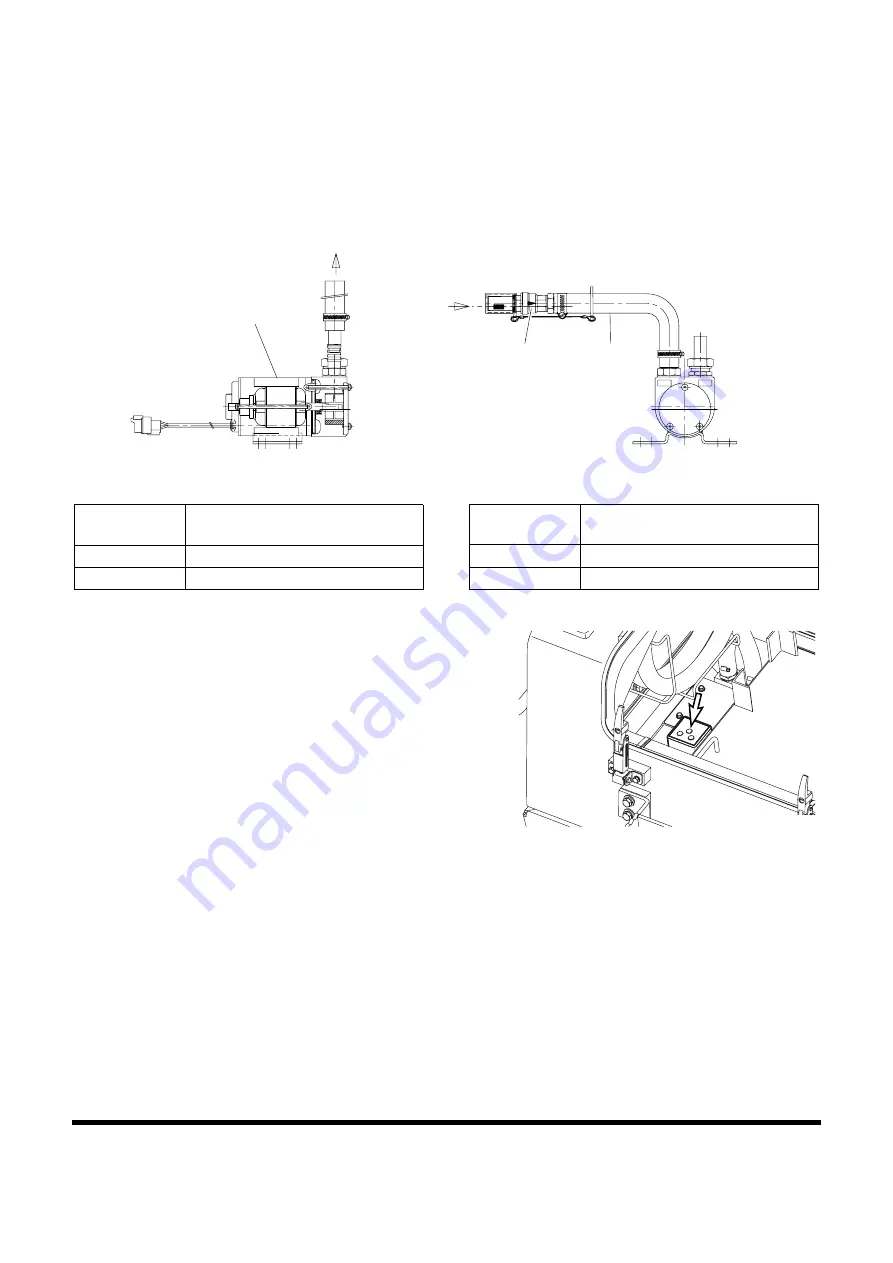

The transfer pump is used to transfer fuel from a refueling

source to the fuel tank. A check valve is installed in the inlet

hose to prevent fuel from flowing back from fuel tank to source.

A strainer is installed in inlet hose to prevent any foreign material

from being introduced into transfer pump or fuel tank.

A thermal limiter, built into the motor, will automatically shut off

power if motor is overheating to protect it from being damaged.

1.

Insert inlet hose (3, Figure 149) into refueling tank.

2.

Turn fuel pump "ON" press (Figure 150) inside of battery

box on front side.

NOTE:

Transfer pump rate of flow is approximately 100

liters/minute (26.4 U.S. gpm). Use extra care

not to overfill fuel tank so that fuel does not over

flow.

3.

Once fuel transfer is completed automatically "OFF"

position to stop pump.

4.

Lift inlet hose (3, Figure 149) from fueling source and turn

switch to "I" (ON) position for two - three seconds to drain

remaining fuel from hose to fuel tank.

5.

Inlet strainer and return hose (3) to storage position.

Fuel

Fuel Tank

IN

IN

OUT

OUT

1

2

3

FG016185

Figure 149

Reference

Number

Description

1

Body

2

Check Valve

3

Inlet Hose

Reference

Number

Description

FG

0

15806

Figure 150

Содержание DX700LC

Страница 2: ......

Страница 72: ...OP001120 Safety 1 66 ...

Страница 142: ...OP001121 Operating Controls 2 70 ...

Страница 188: ...OP001122 Operation 3 46 ...

Страница 197: ...OP001123 4 9 Inspection Maintenance and Adjustment ...

Страница 282: ...OP001123 Inspection Maintenance and Adjustment 4 94 ...

Страница 298: ...OP000030 Troubleshooting 6 6 ...

Страница 301: ...OP001125 7 3 Specification ...

Страница 304: ...OP001125 Specification 7 6 Working Range FG015858 D C F E 8 A B J L I H d G M K Ground Figure 3 ...

Страница 308: ...OP001125 Specification 7 10 ...

Страница 314: ...950106 00012E Index 8 6 ...