5.7. Turbocharger (for D1146T/PU086T, P086TI)

5.7.1. Maintenance

(by authorized specialist personnel)

The turbochargers do not call for any specific maintenance.

The only points to be observed are the oil pipes which should be checked at every oilchange

for leakage and restrictions.

The air cleaners should be carefully serviced.

Furthermore, a regular check should be kept on charge air exhaust gas pipes. Any leakages

should be attended to at once because they are liable to cause overheating of the engine.

When operating in highly dust or oil-laden atmospheres, cleaning of the air impeller may be

necessary from time to time. To this end, remove compressor casing

(Caution , Do not skew

it!)

and clean in a non-acid solvent, if necessary using a plastic scraper.

If the air compressor should be badly fouled, it is recommended that the wheel be allowed to

soak in a vessel with solvent and to clean it then with a stiff brush. In doing so, take care to see

that only the compressor wheel is immersed and that the turbocharger is supported on the

bearing casing and not on the wheel.

5.7.2. Special hints

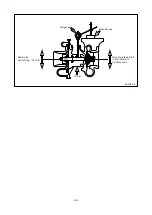

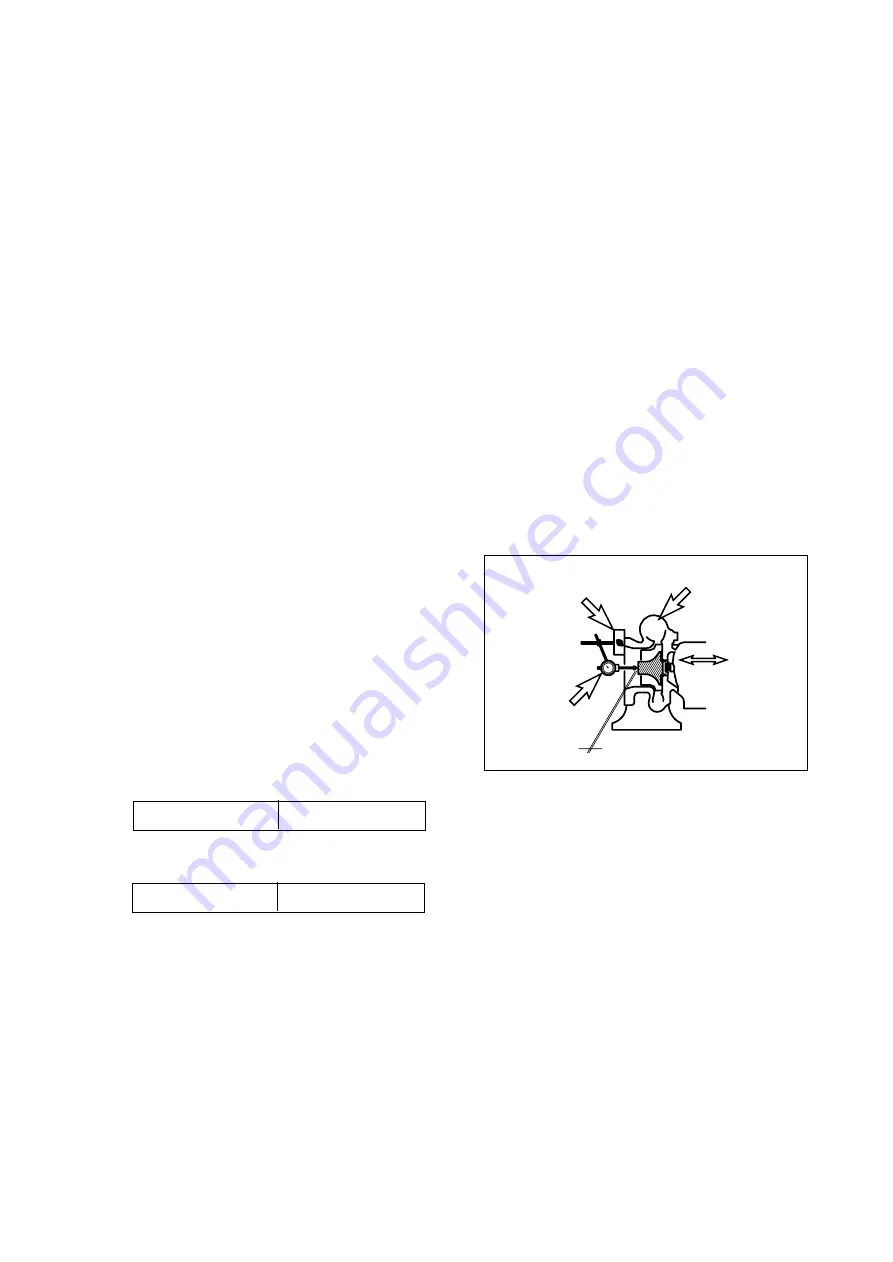

It is recommended that the radial and

axial clearances of the rotor be checked

after every 3,000 hours operation.

This precaution will enable any wear of

the Measuring of axial clearance bear-

ings to be detected in good time before

serious damage is caused to the rotor

and bearings.

•

Measuring rotor axial clearance

•

Measuring radial clearance

- 44 -

EA4M2017

Magnetic vise

Dial gauge

Turbine wheel chamber

Move the turbine

shaft to axial

direction

Wear limit : 0.20mm

Radial clearance

0.65 mm

Axial clearance

0.2 mm

Содержание D1146

Страница 1: ......

Страница 57: ...7 2 Trouble Shooting 53 ...

Страница 58: ... 54 ...

Страница 59: ... 55 ...

Страница 60: ... 56 ...

Страница 61: ... 57 ...

Страница 62: ... 58 ...

Страница 63: ... 59 ...

Страница 134: ... 7 Governor adjustment D1146 130 EA9M4002 0 Injection Pump Speed rpm Rack Position mm 2 4 6 8 10 12 14 C D B A ...

Страница 136: ... 7 Governor adjustment D1146T 132 EA9M4002 0 Injection Pump Speed rpm Rack Position mm 2 4 6 8 10 12 14 C D B A ...