OPERATING INSTRUCTIONS

15

7/53

PRIOR TO STARTING

1. Place the unit in a position that is as level as possible. The design

of the unit permits a 10 degree lengthways and sideways limit on

out of level operation. It is the engine, not the compressor, that is

the limiting factor.

When the unit has to be operated out of level, it is important to keep the

engine oil level near the high level mark (with the unit level).

2. Check the engine lubrication oil in accordance with the operating

instructions in the

Engine Operator’s Manual.

3. Check the compressor oil level in the sight glass located on the

separator tank.

4. Check the diesel fuel level. A good rule is to top up at the end of

each working day. This prevents condensation from occurring in the

tank.

5. Drain the fuel filter water separator of water, ensuring that any

released fuel is safely contained.

6. Open the service valve(s) to ensure that all pressure is relieved

from the system. Close the service valve(s).

8. Check the radiator coolant level (with the unit level).

AIR HOSE RESTRAINT INSTALLATION

Check the air restriction indicator(s). Refer to the

MAINTENANCE

section of this manual.

When starting or operating the machine in temperatures below or

approaching 0°C, ensure that the operation of the regulation system,

the unloader valve, the safety valve, and the engine are not impaired

by ice or snow, and that all inlet and outlet pipes and ducts are clear of

ice and snow.

Safety devices such as hose restraints (whipchecks)must be used to

prevent hose whipping if a connection fails. Whipchecks are to be

constructed of woven stainless steel, galvanized steel wire rope or

chain with aminimum strength adequate for the supplied pressure and

hose diameter. Whipchecks must be fastened to suitable mounting

points or shackles.

The mounts and/or shackles are to be of the same or greater strength

as the whipchecks. An engineer should be consulted about suitability

of whipchecks, mounts, mounting points, shackles and fittings as well

as strength rating of materials. Whipchecks must be used at the hose

origination, termination and each hose to hose connection.

Hoses can fail in areas other than at connecting points and require

daily inspection of the hoses for:

•

Cuts, cracks or kinks

•

Weakened clamps due to rust and corrosion

•

Damaged connections

•

Deformity

•

Incorrect or incompatible components or fittings

•

Any visual damage

Hoses must be selected that are rated for the application as to the

maximum pressure and temperature to be encountered as well as

compatible with the materials being conveyed inside the hose. Hoses

must be compatible with the compressor oil.

CAUTION:

Do not overfill either the engine or the compressor with

oil.

CAUTION:

Use only specified diesel fuels (see engine section for

details)

CAUTION:

When refueling:-

•

switch off the engine.

•

do not smoke.

•

extinguish all naked lights.

•

do not allow the fuel to come into contact with hot surfaces.

•

wear personal protective equipment.

7.

CAUTION:

Do not operate the machine with the canopy/doors in

the open position as this may cause overheating and operators to

be exposed to high noise levels.

Содержание 7/53

Страница 2: ......

Страница 4: ......

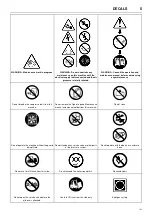

Страница 11: ...DECALS 7 7 53 Engine oil drain...

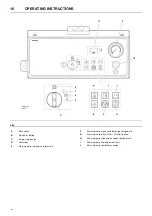

Страница 15: ...GENERAL INFORMATION 11 7 53 7 53 FIXED HEIGHT RUNNING GEAR 7 53 VARIABLE HEIGHT RUNNING GEAR...

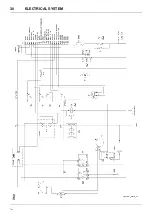

Страница 34: ...30 ELECTRICAL SYSTEM 7 53 7 53...

Страница 36: ...32 ELECTRICAL SYSTEM 7 53 7 53...

Страница 44: ...40 OPTIONS 7 53 WATER SEPARATOR MAINTENANCE FIGURE 4 FIGURE 5 FIGURE 1 FIGURE 2 FIGURE 3...

Страница 58: ......

Страница 59: ......

Страница 60: ......