Dodge Industrial, Inc.

1061 Holland Road

Simpsonville, SC 29681

+1 864 297 4800

All Rights Reserved. Printed in USA.

MN16007 07/22

*16007-0722*

© DODGE INDUSTRIAL, INC.

AN RBC BEARINGS COMPANY

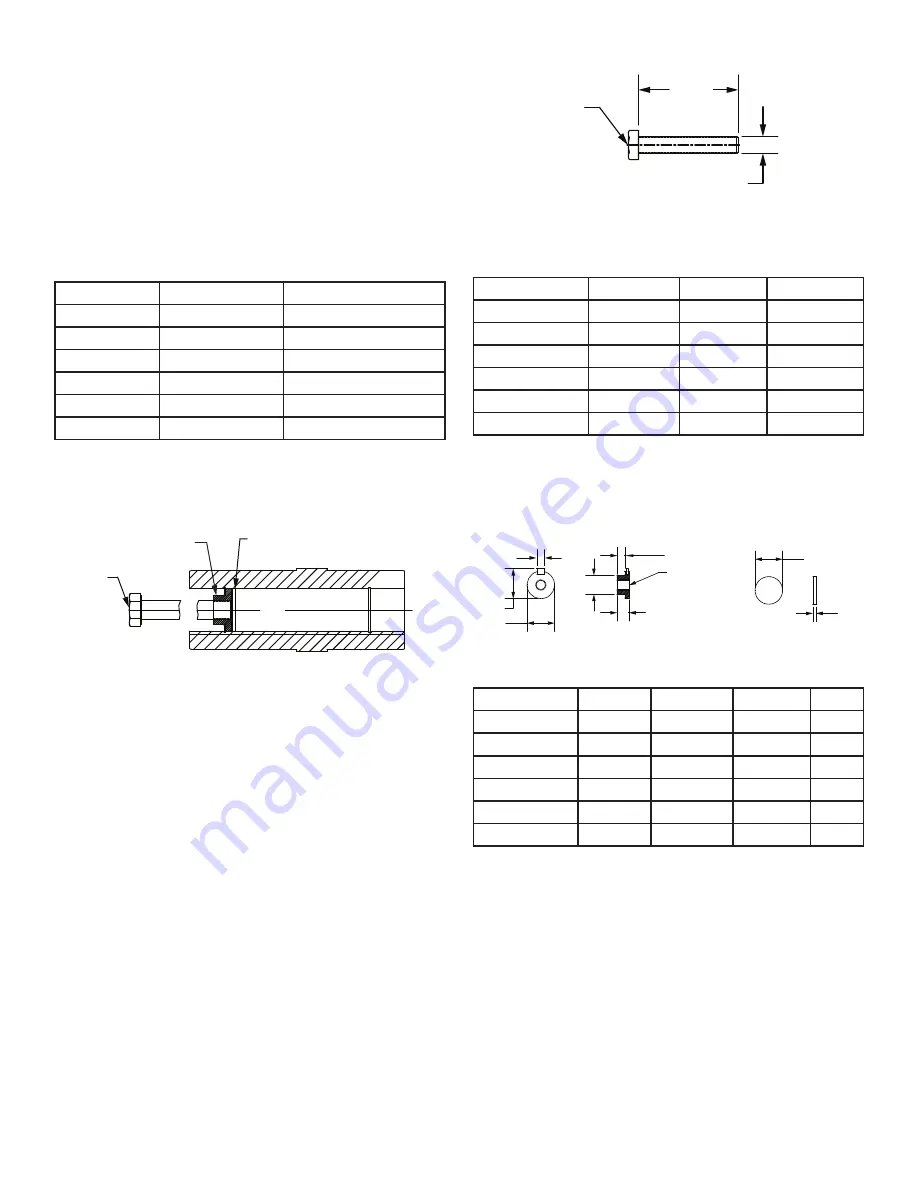

Table 3–Removal Bolt Dimensions

Unit Size

M1

VB1

S

MSM/RHB 38

3/8-16

6.00

0.31

MSM/RHB 48

5/8-18

7.00

0.5

MSM/RHB 68

3/4-10

8.00

0.63

MSM/RHB 88

7/8-14

9.50

0.81

MSM/RHB 108

7/8-14

12.50

0.81

MSM/RHB 128

7/8-14

14.00

0.81

Note: The retaining bolt supplied with the gear unit cannot be used for the

purpose of disassembly and must be replaced by the bolt in Table 3. The round

keyed nut and disk should be made from 1045 steel and the removal bolt should

be a minimum of SAE Grade 5.

Table 4–Removal Rounded Key Nut and Disk Dimensions

Unit Size

Y Max

UY Max

ØUE

GF

MSM/RHB 38

0.250

1.367

1.245

0.12

MSM/RHB 48

0.312

1.52

1.370

0.12

MSM/RHB 68

0.375

1.669

1.495

0.25

MSM/RHB 88

0.500

2.22

1.995

0.25

MSM/RHB 108

0.625

2.65

2.370

0.31

MSM/RHB 128

0.625

3.03

2.745

0.31

7. Turn reducer upright or on its side. Use caution not to damage

either type of seals and install drive shaft through the adapter

housing into the reducer. Line up the keyway in the drive shaft

with the keyway in the reducer hub bore. Slide or gently tap

key into reducer through the input shaft side of the output

hub.

8. Install the retaining ring (411) into the snap ring groove. Install

keeper plate (402) flush against retaining ring.

9. Install spring washer (406) and retaining bolt (405) making

sure the drive shaft is fully seated into the reducer. Tighten

the retaining bolt to the tightening torque specified in Table 2.

Install dust cap (401).

Table 2–Tightening Torques for Retaining Bolt

Unit Size

Bolt Thread Size

Torque

MSM/RHB 38

3/8-16

248 in-lb

MSM/RHB 48

3/8-16

248 in-lb

MSM/RHB 68

5/8-11

611 in-lb

MSM/RHB 88

3/4-10

1221 in-lb

MSM/RHB 108

3/4-10

1221 in-lb

MSM/RHB 128

3/4-10

1221 in-lb

DRIVE SHAFT REMOVAL

To remove the drive shaft from the reducer, the following steps

are required. Reference Figure 2 for disassembly arrangement.

1. Remove the dust cap (401), the driveshaft retaining bolt

(405) and lock washer (406), the keeper plate (401) and the

retaining ring (411).

2. For ease of disassembly, it is recommended that the following

tools be made and used as described: (A) round keyed nut,

dimensions in Table 3, (B) removal bolt, dimensions in Table

4.

3. The round keyed nut (A) is inserted into the free space

between the retaining ring in the gear unit’s hollow shaft and

the end of the machine’s drive shaft.

4. The removal bolt (B) is screwed into the nut (A) which

presses a disk (C) against the screw conveyor drive shaft.

The resulting force pushes the gearbox off of the drive shaft.

5. The driveshaft can now be easily removed from the reducer

by pulling the driveshaft straight out.

Figure 2 - Screw Conveyor Diassembly

B

A

C

ROUND KEYED NUT

UY

Y

ØUE

FG

ØFH

FV

M1-TAP

DISK

ØUE

GF

REMOVAL BOLT

M1

VB1

S