Operating instructions

64426 A 03/35

page 11 - 14

5.4.2

Changing the scale setting (adjustment

for customer settings)

The purpose of setting the scale on the rotary knob is to ensure that the fineness

of the ground coffee matches the fineness setting shown on the scale. The

machine is supplied complete with a factory setting and is ready for operation.

Alter the scale setting:

if the fineness of the coffee after grinding does not match the scale and is

therefore not as required.

if a setting for a particular grinding fineness is needed.

IMPORTANT

Only the maintenance staff should be allowed to adjust the scale settings!

Procedure

1. Place a bag under the delivery tube for the

ground coffee.

2. Switch the machine on.

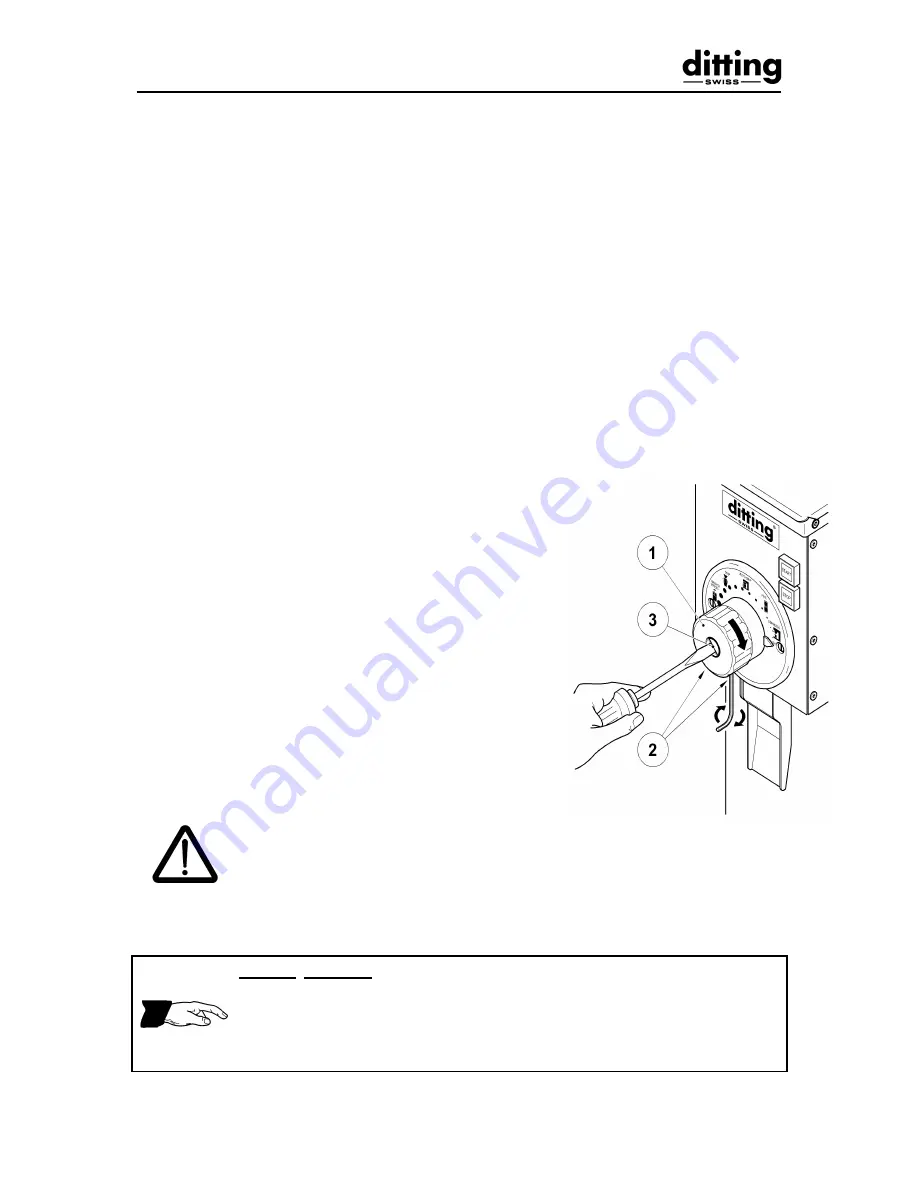

3. Turn the rotary knob (1) in a clockwise

direction as far as the catch point.

4. Use the hexagonal Allen key (approx. 3

turns) to release the studs (2).

5. Turn the centre screw head (3)

- for greater grinding fineness:

clockwise

- for coarser grinding:

anti-clockwise.

CAUTION

If you hear a slight sound (grinding discs in contact with each other), this

means that the gap between the grinding discs is too small and must be

increased! (Correct by turning anti-clockwise!)

6. Tighten the studs (2) once more.

Checking the setting:

When turning the adjusting knob from scale position Turkish to French Press

there must on no account be a sound of metal parts rubbing together.

There must be

no sound

of grinding discs rubbing together at scale position

Turkish = excessive wear of grinding discs. If there is a sound, grinding must

be set more coarsely

(see 5.5).