17

Maintenance

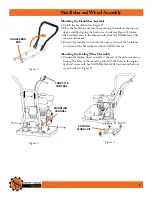

Replacing the V-Belts

1. Loosen 4 engine mount bolts on the plate compactor just enough

to move the engine slightly, but do not remove the bolts entirely

(see Figure 9).

2. Loosen the jam nuts and bolts (see Figure 10).

3. Push the engine toward the front of the plate and slip the v-belts

off of the pulleys (see Figure 11).

4. Install new belts. It is best to replace both belts even if only one

shows wear.

5. Move the engine back and test the belt tension.

5. Tighten the jam nuts against the bracket and tighten the engine

bolts.

6. Replace the belt guard.

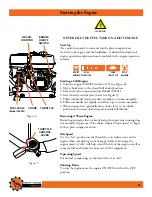

Exciter Lubrication

The exciter housing is pre-filled with automatic transmission fluid

(Dextron III or equivalent) by the manufacturer. The fluid should

be changed every 200 hours of operation.

1. Let the exciter cool before attempting to change the fluid.

2. Remove the belt guard and v-belts (see Figures 8, 9 & 11).

3. Remove bolts that secure the deck to the housing (see Figure 12).

4. Lift the deck and engine up and detach from the housing.

5. Remove the drain plug from the top of the exciter housing. Tilt

upside down so fluid drains (see Figure 13).

6. Return plate to upright position.

7. Fill exciter with 2.70 fluid ounces/80ml (2.0 fluid ounces/60ml

for the Model 104950) of automatic transmission fluid, Dextron

III or equivalent, (see Figure 14).

8. Apply pipe sealant to drain plug and reinstall.

9. Reattach the deck and engine to the plate housing. Reattach the

v-belts and belt cover.

Figure 11

EXCITER

PULLEY

CLUTCH

PULLEY

V-BELTS

Figure 12

Figure 13

4

PLACES

4

PLACES

DRAIN

PLUG

Figure 14