16

Maintenance

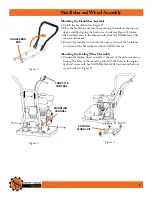

Checking the V-Belts

V-Belts must be in good condition and tensioned properly to

ensure maximum performance of the plate compactor.

1. Remove the 4 hex bolts that secure the belt guard to access

the v-belts (see Figure 8).

2. Check the condition of the v-belts. If there is signs of

cracking, fraying or glazing, replace the belts as soon as

possible.

3. Check the belt tension by pressing on the center of the belt

length. The normal deflection on each side should be 3/8”

(9mm) - 1/2” (13mm) while applying moderate pressure

with thumb or finger.

Tensioning the V-Belts

1. Loosen 4 engine mount bolts, 2 on each end of the engine

block, just enough to move the engine slightly, but do not

remove the bolts entirely (see Figure 9).

2. Loosen the jam nuts leaving enough space between the nut

and the bracket (see Figure 10).

3. Push the engine toward the back of the plate by turning the

adjustment bolts to remove any slack in the v-belts.

4. When the v-belts are tensioned correctly, there should be 3/8”

(9mm) to 1/2” (13mm) of movement when the belt is pressed

firmly in the center of the belt length. If the adjustment bolts

can not be adjusted enough to increase the belt tension, then

the belts should be replaced.

5. Tighten the jam nuts against the bracket and tighten the

engine bolts.

6. Replace the belt guard.

Note:

When adjusting the belts, make sure that the clutch

pulley and the exciter pulley are in alignment.

JAM

NUTS

ADJUSTMENT

BOLTS

Figure 8

Figure 9

Figure 10