23

Casefeed Window Cuff

The Casefeed Window Cuff (above photo) is now adjustable.

This will allow for faster and more reliable case feeding of

longer and shorter rifle cases (i.e. .300 AAC Blackout,

7.62x39). The window now has six positions that the Cuff can

be adjusted to. Starting from the left, the third position from the

left will give you the standard opening width of the previous

unit. This adjustment will work for all pistol and most all of

your standard rifle cartridges. With the Window Cuff adjusted

to the full left position it will allow for faster case feeding of

larger rifle calibers. With the window adjusted to the full right

position it will allow for case feeding of shorter bottleneck rifle

cases (i.e. .300 AAC Blackout, 7.62x39) utilizing standard rifle

Casefeed Plates. The Cuff can be adjusted by loosening the

black knurled nut, it is incorporates a 3/16” hex. Slide the Cuff

into position, making sure that the small leg in locked into the

adjustment notch for the desired opening size, and retighten

the nut to no more than 10 to 12 inch-pounds to lock it into

position.

Case Deflector Block

The Casefeed Bowl utilizes an adjustable Case Deflector

Block (above photo). The deflector has two positions for

operation, fully lowered (see photos next column) for pistol and

fully raised for rifle cartridges. The block can be adjusted by

loosening the two #8 screws with a 3/32” hex wrench. Slide

the block to the desired position based on pistol or rifle

cartridge and tighten the two screws to no more than 5 to 7

inch-pounds to lock the Case Deflector Block into position.

Troubleshooting the Casefeeder

Casefeeding

A. Casefeeder is on but will not rotate.

1. Brass caught under casefeed plate.

2. Casefeed is too full.

3. Bad micro-switch.

B. Cases are falling down tube upside down jamming in the

top tube, etc.

1. Using the wrong casefeed plate for that caliber.

2. Casefeeder is too full.

3. The machine is not secured to a sturdy enough bench.

C. Casefeed tube (13761 or 14392) appears too short.

1. Casefeed is not pushed down all the way on the

casefeed mounting post (13831).

D. Cases hanging up at micro-switch or micro-switch

inoperative.

1. Check the angle of the switch lever and adjust as

necessary.

a. Too sharp an angle will cause cases to hang up.

b. Too shallow an angle will cause incomplete shutoff.

E. Cases jamming at the casefeed arm (13716).

1. Wrong size or loose body bushing for caliber being

loaded.

2. Operating machine too fast.

3. Short stroking the machine.

4. Dented or squashed cases.

NOTE: If the power cord ever needs replacing, use only a

qualified electrician to install the new power cord or return it

to the factory.

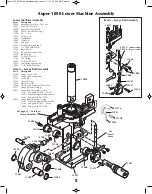

How to set the adjustable Casefeed Window Cuff and Case Deflector Block

Case Deflector Block Fully Lowered

Case Deflector Block Fully Raised

Super 1050 2018 New Casefeeder.qxp_Layout 1 1/31/18 6:47 AM Page 23