18

Place a bullet on the belled case

mouth and lower the toolhead. Then,

raise the toolhead just enough to inspect

the bullet without indexing the

shellplate. If the bullet is not seated deep

enough, screw the seating die down 1/2

turn at a time. As a guide, one full turn

moves the die down about 70 thou-

sandths of an inch, about the thickness of

a nickel. Again, cycle the machine and

inspect the seating depth. Repeat these

steps as necessary until the correct over-

all length is achieved. Use a dial caliper

or equivalent to measure the overall

length of the cartridge. Check the overall

length of the round against the informa-

tion in your reloading manual.

Once you have obtained the proper

OAL, replace the cartridge into Station 7

and lower the toolhead. Using a 1"

wrench to turn the lock ring and a 7/8"

wrench to hold the die body, snug the

lock ring.

Note: If you ever load a cartridge that

you are unhappy with, you can use a

Dillon bullet puller to reclaim your com-

ponents.

Station 8 - Installation and adjustment

of the Crimp Die

Screw the crimp die into Station 8.

Screw it down until it is flush with the

bottom of the toolhead. This is a good

starting point for the crimp adjustment.

Place a cartridge with a properly

seated bullet into Station 8.

Lower the toolhead and continue to

screw the die down until it touches the

cartridge.

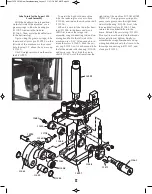

Fig. 58

Raise the toolhead and screw the die

down 1/8 of a turn, lower the toolhead.

Raise the toolhead halfway and in-

spect the cartridge. If the bell is still pres-

ent, or the desired amount of crimp has

not been achieved, give the die a 1/8

turn down and try again. Continue mak-

ing small adjustments to your crimp die

until the desired amount of crimp has

been achieved.

Once the adjustment is complete,

place the case back into Station 8 and

lower the toolhead. Using a 1" wrench

to turn the lock ring and a 7/8" wrench

to hold the die body, snug the lock

ring.

Note: When adjusting the crimp die it

is important to know what to look for.

Check that the crimp: Looks OK, allows

your firearm to function consistently and

the bullet feels tight in the case.

The drawing of case #3 (above) is a

depiction of a case that has been over

crimped by adjusting the crimp die down

(clockwise) too far. Note the defined line

below the mouth of the case and the

bulge below the line. This is not a proper

crimp. This line is the direct result of the

cartridge being over crimped. A line like

this will only appear if the crimp die is

adjusted down too far. Warning: Over

crimping .45ACP, .38 Super, 9mm,

etc., can actually cause the bullet to

be loose in the case.

Adjustments for calibers 9mm, .38 Sp.,

.45 ACP and for hot loads that have

been fired many times

Configuration 1

To begin, place a military case (sized,

decapped and unswaged) into Station 3.

Screw the back-up rod (#12749*)

down two turns into the toolhead

(#20420). Pull the handle.

Using a wrench turn the back-up rod

(#12749*) down until it hits the inside

bottom of the case. Note: Do not force

the expander as this will damage the

case and the shellplate. Now secure the

lock ring (#14062). Raise the handle.

Screw the eyebolt (#13245) all the

way into the swager. Grease the clevis

pin (#13522) heavily.

Put the swager into position. Push the

clevis pin through the connecting rod

and eyebolt and secure with the hitch

pin (#13840). Replace the swage cover

(#13064).

With the military case still in Station

3, pull the operating handle down with

your left hand. Now turn the swager

upward with your right hand until it

meets resistance. With your left hand

raise the operating handle about 10

inches. With your right hand turn the

swager up a 1/4 turn. Cycle the handle

down.

Raise the handle just enough to re-

move the case and inspect the primer

pocket to see the amount of swaging

being done. The swager should leave a

radiused entrance on the primer pocket.

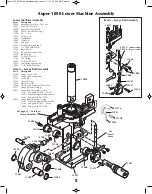

Fig. 59

Turn the swager in, using 1/4 turn in-

crements until you achieve the proper

swage. Secure the jam nut (#13682).

Note: Do not over swage. This condi-

tion will cause damage to the shellplate

(#12600*).

When your swager is properly ad-

justed you will feel resistance during the

final 1/2" to 1" of the downward stroke of

the handle.

Adjustments for rifle calibers

Configuration 2

To begin, place a military case (sized,

decapped and unswaged) into Station 3.

Remove the back-up rod (#12749*)

from the back-up die (#12184).

With the operating handle in the down

position, screw the back-up die into Sta-

tion 3 until the die comes into contact

with the shellplate. Now back the die out

one full turn and secure it in place with

the lock ring (#14067).

Leave the handle in the down posi-

tion. With a wrench, screw the back-up

rod into the back-up die. Turn the back-

up rod down until it touches the inside

Fig. 58 - Cutaway crimp die shows the

area being crimped while the case is being

fully supported by the die body.

Fig. 59 - Note the difference between the

swaged primer pocket (left) and the

unswaged primer pocket (right).

3

2

1

Super 1050 2018 New Casefeeder.qxp_Layout 1 1/31/18 6:47 AM Page 18