OPERATOR’S MANUAL

PM300E and PM332E Planter Monitors

11001-1423-200710

42 / TROUBLESHOOTING

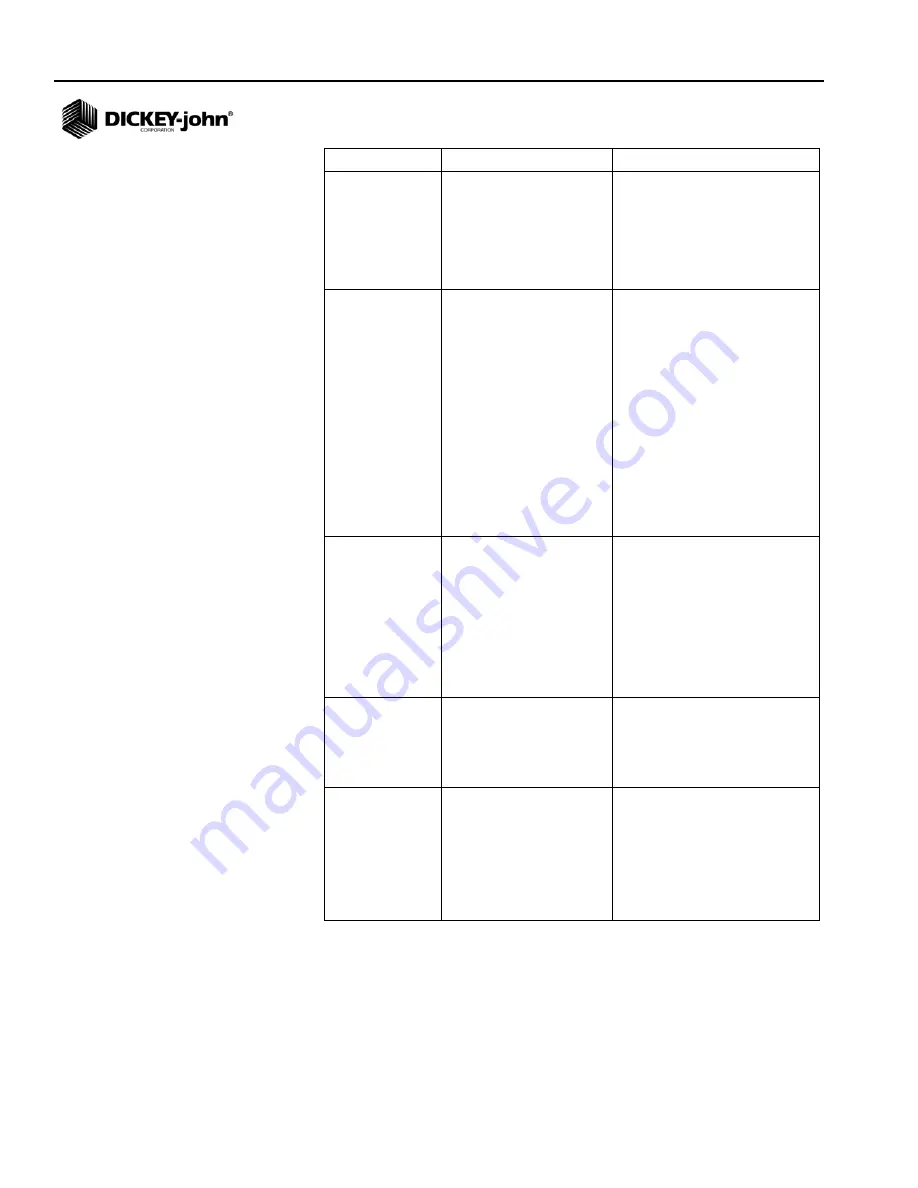

Alarm

Probable Cause

Corrective Action

Monitor will not

power on.

1. Blow console fuse.

2. Poor battery connection

3. Low battery voltage

4. Defective console

1. Check fuse (located near battery

connection). If needed, replace

replace with 5.0 amp fuse maximum.

If fuse blow again, check all

harnesses for pinches or breaks that

can cause power short to ground.

2. Be sure connections are clean

and tight.

Row failure or hi/

low alarm when

row is planting

properly.

1. Seed sensor coated with

dirt.

2. Faulty sensor or harness.

3. Defective console.

1. Clean sensor using a dry bottle

brush.

2. Drop seed down the seed tube or

place a dry bottle brush down the

seed tube to trigger sensor. Observe

if troubleshooting sensor LED

mounted to the tube blinks. If sensor

does not blink, replace the sensor. If

the sensor LED blinks, check

harness for damage or pinched

wires. If the sensor does not have

an LED, swap harness connection

with adjacent sensor to determine if

sensor is damaged.

3. Console is damaged. Contact

dealer or DICKEY-john Europe

(+33-141-192-180).

Hopper alarm

does not sound

when hopper is

empty.

1. Hopper sensor coated with

dirt.

2. Faulty sensor or harness

shorted to ground.

3. Defective console.

1. Clean sensor using a dry bottle

brush.

2. Swap harness connection with

another sensor to determine if

sensor or harness is damaged. Use

service screen if another sensor is

not available. Replace sensor or

repair harness.

3. Console is damaged. Contact

dealer or DICKEY-john Europe

(+33-141-192-180).

Hopper alarm

sounds when

hopper is full.

1. Faulty sensor or harness

open.

2. Defective console.

1. Swap harness connection with

another sensor to determine if

sensor or harness is damaged. Use

service screen if another sensor is

not available. Replace sensor or

repair harness.

System voltage

alarm.

1. Low battery voltage.

2. Poor battery connection.

3. Damaged harness.

1. Console voltage must be at least

10V. If low, recharge or replace

battery.

2. Be sure connections are clean

and tight. Inspect harness for

damage.

3. Check all harnesses for pinches or

breaks that can cause power or 8V

sensor power short to ground.

Содержание PM300E

Страница 4: ...OPERATOR S MANUAL PM300E and PM332E Planter Monitors 11001 1423 200710 2 SAFETY NOTICES...

Страница 8: ...OPERATOR S MANUAL PM300E and PM332E Planter Monitors 11001 1423 200710 6 INTRODUCTION...

Страница 10: ...OPERATOR S MANUAL PM300E and PM332E Planter Monitors 11001 1423 200710 8 MAJOR FEATURES...

Страница 14: ...OPERATOR S MANUAL PM300E and PM332E Planter Monitors 11001 1423 200710 12 INSTALLATION...

Страница 30: ...OPERATOR S MANUAL PM300E and PM332E Planter Monitors 11001 1423 200710 28 AUXILIARY MODES...

Страница 43: ...OPERATOR S MANUAL PM300E and PM332E Planter Monitors 11001 1423 200710 TROUBLESHOOTING 41 TROUBLESHOOTING...

Страница 46: ...OPERATOR S MANUAL PM300E and PM332E Planter Monitors 11001 1423 200710 44 TROUBLESHOOTING...

Страница 48: ...OPERATOR S MANUAL PM300E and PM332E Planter Monitors 11001 1423 200710 46 CONNECTOR PINOUTS...