AIRCRAFT

DA 40 Series AMM

Temporary Revision

NLG Inspection & Maintenance

Details Steps/Work Items

Key Items

10.

Examine the elastomer pack center tube:

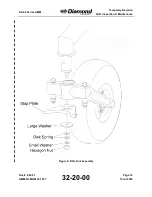

Remove the elastomer pack.

Remove the elastomer elements.

Examine the elastomer pack center tube:

If the center tube shows signs of

deformation: Replace the center tube (refer

to Section 32-20).

If the center tube shows signs of wear:

Replace the center tube if a radial wear limit

(depth measured) of 0.8 mm is exceeded.

Remove the elastomer elements in the event

that they are worn or cracks are found.

Adjustment and installation of the elastomer

pack.

Refer to Section 32-20.

11.

Examine the top hat profile in the bottom of the

fuselage for delamination and disbonding. Look

specially in the area of the bearings for the

nose-gear assembly.

12.

Remove the load from the nose-gear and examine

it. Look specially for more than the usual play.

13.

Examine the control surfaces. Look specially for:

Correct attachment of the hinges.

Correct attachment of the mass balance to the

structure.

14.

Examine the leading edge of the wing for damage.

15.

Examine the area of the spar attachments to the

wing shells. Look specially for cracks.

16.

Examine the leading edge of the horizontal and

vertical stabilizers for damage.

17.

Examine the engine mount.

Doc # 6.02.01

AMM-TR-MÄM 40-1037

05-50-00

Page 11

13 Jul 2020