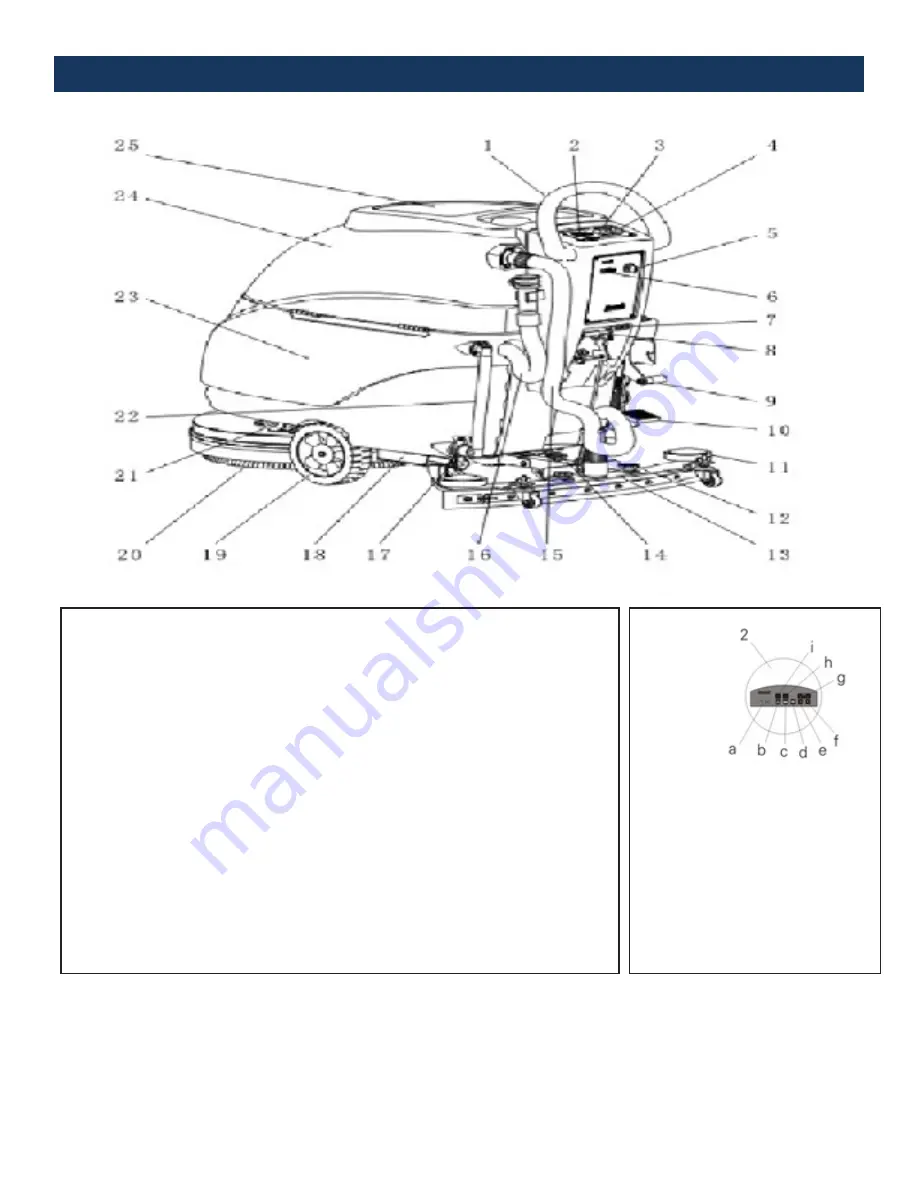

DIAGRAMS OF THE MACHINE

1. Handlebar

2. Control Panel

3.

Suction Motor Button (b)

4.

Brush Motor Button (c)

5. Power Switch

6. Timer

7. Socket for Charger

8.

Squeegee Height Adjusting Handle

9. Manual Pressurized Handle

10. Brush Pedal

11. Guard Wheel

12.

Fixed Handle of Squeegee

13. Squeegee

14. Regulating Handle of Squeegee

15. Water Suction Pipe

16. Water Drain Out Pipe

17. Water Valve

18. Metal Frame

19. Wheel

20. Brush

21. Clean Water Filtration

22. Water Level Indicator

23. Solution Tank

24. Dirty Water Tank

25. Dirty Water Tank Cover

a. Battery Indicator

b. Suction Motor Button

c. Brush Motor Button

d. Brush Install and Release Button

e. Rate Regulation (slow) Button

f. Rate Regulation (fast) Button

g. Rate Indication

h. Indication of Operation of Brush

Motor

i. Indication of Operation of Suction

Motor