17

GB

11.

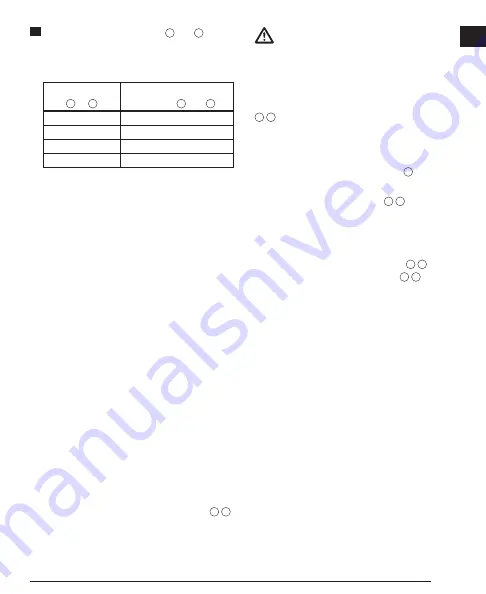

Measure the distance between

a

and

f

. If the

measurement is greater than the values shown

below, the laser must be serviced at an authorized

service center.

Distance from

a

to

b

Allowable Distance

Between

a

and

f

4.0 m

3.5 mm

5.0 m

4.4 mm

6.0 m

5.3 mm

7.0 m

6.2 mm

Using the Laser

Leveling the Laser

As long as the laser is properly calibrated, the laser is

self-leveling. Each laser is calibrated at the factory to

find level as long as it is positioned on a flat surface

within average ± 4° of level. No manual adjustments

are required.

If the laser has been tilted so much that it cannot

self-level (> 4°), the laser beam will flash. There are

two flashing sequences associated with the out of level

condition.

•

Between 4° and 10° the beams flash with a constant

blink cycle

•

At angles greater than 10° the beams flash with a

three blink cycle.

When the beams flash THE LASER IS NOT LEVEL

(OR PLUMB) AND SHOULD NOT BE USED FOR

DETERMINING OR MARKING LEVEL OR PLUMB.

Try repositioning the laser on a more level surface.

Using the Pivot Bracket

The laser has a magnetic pivot bracket (Figure

H

1

)

permanently attached to the unit.

WARNING:

Position the laser and/or wall mount

on a stable surface. Serious personal injury

or damage to the laser may result if the laser

falls.

•

The bracket has a fine adjustment knob

(Figure

H

2

) to help you line up the laser beams. Place the

unit on a flat level surface and turn the knob to the

right to move the beams to the right, or turn the knob

to the left to move the beams to the left.

• The bracket has a keyhole slot (Figure

I

) so it can

be hung from a nail or screw on any kind of surface.

• The bracket has magnets (Figure

J

1

) which allow

the unit to be mounted to most upright surfaces

made of steel or iron. Common examples of suitable

surfaces include steel framing studs, steel door

frames, and structural steel beams. Before attaching

the pivot bracket against a stud (Figure

J

2

), place

the Metal Enhancement Plate (Figure

J

3

) on the

opposite side of the stud.

Maintenance

• To maintain the accuracy of your work, check the

laser often to make sure it is properly calibrated.

See Field Calibration Check.

• Calibration checks and other maintenance repairs

may be performed by D

E

WALT service centers.

• When not in use, store the laser in the kit box

provided. Do not store your laser at temperatures

below -5˚F (-20˚C ) or above 140˚F (60˚C).

• Do not store your laser in the kit box if the laser is

wet. The laser should be dried first with a soft dry

cloth prior to storage.

Cleaning

Exterior plastic parts may be cleaned with a damp

cloth. Although these parts are solvent resistant,

NEVER use solvents. Use a soft, dry cloth to remove

moisture from the tool before storage.

Содержание DCE089G18

Страница 1: ...DCE089G18 3x360 12V 18VLineLaser GB NL GR I FIN D DK ES NO F SE PT TR www 2helpU com ...

Страница 2: ...Figures 2 A B ...

Страница 3: ...3 3 1 2 6 4 7 5 C ...

Страница 4: ...Figures 4 a b a c a b a b 33 10m _ c b 1 2 3 D ...

Страница 5: ...5 a b b a 33 10m _ b c b a c c a c 1 2 3 E ...

Страница 6: ...Figures 6 g h e f d c d c a b c g b a 2 h d 8 2 5m _ 1 2 3 F ...

Страница 7: ...7 90 a a a f b c a f c b c e e 14 4m _ 14 4m _ 14 4m _ b 1 2 3 G ...

Страница 8: ...Figures 8 3 H 1 I J 2 2 1 ...

Страница 9: ...9 5 8 11 1 4 20 K L 1 6 5 2 4 3 ...

Страница 10: ...Figures 10 N M ...

Страница 53: ...53 I Garanzia Visitare il sito web www 2helpU com per informazioni recenti sulla garanzia ...

Страница 150: ...Notes ...

Страница 151: ......

Страница 152: ... 2020 DeWALT Industrial Tool Co DeWALT Europe D 65510 Idstein Germany 65509 N856410 October 2020 ...