-

6

-

CAUTION:

The air cap can be immersed in solvent for cleaning. If orifices are clogged, use a broom

straw or toothpick to remove obstruction. Never use a steel wire or hard instrument. This will

damage air cap and result in a distorted spray pattern.

NOTE:

Do not immerse any plastic parts in solvent for long time.

CAUTION:

Lubrication

Do not lubricate to any portions where not instructed

Lubricate one drop of Gun Lube SSL-10 daily to the following portions.

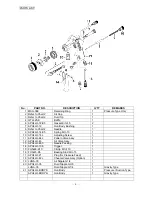

Lubricate regularly, Trigger Bearing Stud (16), Air Valve Stem (12) where it enters the valve body and

the Needle (8) where it enters the Packing Nut (13).

When installing Air Cap (2), make sure no foreign materials adhered on Retaining Ring (1) and thread

of Baffle (4) and then oil one drop of Gun Lube SSL-10.

Apply non-silicone grease lightly on Needle Spring (9) and Air Valve Spring.

Do not apply to much grease as it may clog the air passage.

Lubricate daily to the following portions. For lubrication, SSL-10 Gun Lube is recommended.

A) Trigger Bearing Stud

B) Needle

Packing

C) Thread of Pattern Valve

Thread of Adjusting Screw

D) Retaining

Ring

E) Air Valve Stem

REPLACEMENT OF PARTS

CAUTION:

Be careful not to touch the point of Needle (8) as it is sharp.

When removing Fluid Tip (3), Adjust Screw (10) and Needle Spring (9) should also be removed and

Needle (8) should be withdrew or retreated. Turn the Pattern Valve (11) fully counter-clockwise

Tools should be 1/2” offset wrench, box wrench or DeVilbiss wrench APOLLO-34, do NOT use open

wrench or adjustable wrench.

Recommended torque of fluid tip is 20N.m.

To replace Fluid Inlet Nipple (20) and Air Inlet Nipple (19), apply LOCKTIGHT 242 and tighten.

Recommended torque 16 - 20N

・

m.