-

5

-

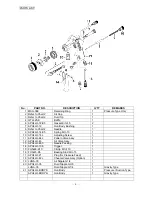

Chart 2 Air Cap, Fluid Tip and Needle Combination

Air Cap

Lapped Set (Tip & Needle)

Remarks

Part Number

Part Number

Orifice Size

(mm)

Fluid Tip

Stamp

Fluid Feed

APO-4046-DFX 1.1

DFX

APO-4046-DFW 1.6

DFW

AV-1239-805

APO-4046-GD 0.7

GD

Pressure

APO-4046-DFX 1.1

DFX

APO-4046-DFW 1.6

DFW

AV-1239-80

7

APO-4046-GD 0.7

GD

Pressure

AV-1239-805MT

APO-4046-FF

APO-4046-FX

APO-4046-G

1.4

1.1

0.7

AV-1915-FF

AV-1915-FX

AV-1915-G

Pressure

GTI-407-110

(

with retaining ring

)

GTI-213-14

Fluid Tip

GTI-413-K

Needle (1.4 mm)

GTI-213-14

Gravity

Suction

INSTALLATION/OPERATION

NOTE

: The air supplied to spray gun must be cleaned air which any water, oil and solid material

removed. To set up the Mist Separator and Air Transformer near the gun is recommended.

As LVMP gun consumes less air, it is not necessary to use thicker hose compare to HVLP gun.

CAUTION:

Adjust Needle Packing (13) before start using new gun. Tighten the Packing Nut (13)

gradually and then to adjust the needle moving smoothly, untighten a little where the Needle (8) is not

well pulled back

The Air Cap Pressure is set at 0.2MPa when Gun Inlet Pressure is 0.25MPa. It is recommended

to check the Air Cap Pressure just in case with the Air Cap Test Kit which is available separately.

The recommended spray distance is 150

~

200mm. If the spray distance is too far, good result does

not appear. Also, in order to get uniform finishing, the spray gun should be hold vertically toward the

painting surface.

To adjust the fluid delivery, keep the needle full open, not tightening the Adjusting Screw (10), so that

the delivery can be adjusted at the material supply line. It leaves the abrasion of the Fluid Tip (3) and

the Needle (8) the minimum.

The paint should be filtered through 60

~

90 mesh filter before use.

MAINTENANCE

Daily lubrication and cleaning is necessary to maintain the best condition of the gun.

NOTE:

Clean the spray gun after used with clean solvent and empty the inside of the hose.

To clean the fluid passage, after removing extra paint, through the appropriate solvent and flush down

the residual paint. When blowing the paint inside the hose and the gun back to pressure tank by

pressuring, follow the following procedure:

Release the pressure in the tank and loosen the lid a little, then make one rotation to loosen the

Retaining Ring (1), which presses the gun cap. Press the point of the gun with cloth and pull the

Trigger (14). The atomizing air then flows back to the fluid hose and the paint in the hose is flushed

back to the tank.

CAUTION:

To clean the gun body, wipe exterior with solvent dampened cloth. Do not submerge the

gun body in solvent as any solids may get into the air passage and cause troubles.