TB-3006

Page 3 of 4

Under normal conditions the ionizer will attract dirt and dust

(especially on the emitter and fan guards). To maintain

optimum performance, cleaning must be done on a regular

basis. The emitter pins should be cleaned at least every 6

months. However, more frequent cleaning may be required

if used in environments with more contaminants.

Theory of Operation

By definition, materials that are insulators cannot have

static charges removed via grounding as they do not

conduct electricity. Ionizer emitters flood an area with

millions of positive and negative charged ions to neutralize

statically charged insulators.

Desco overhead ionizers employ a safe non-nuclear

Steady-State DC ionization source. Steady DC systems

consist of separate negative and positive ion emitters

connected by a pair of high-voltage cables to their

respective high-voltage power supplies. The ionizer’s

unique, closed loop monitoring circuitry monitors ion output

and automatically adjusts the unit to reach an equilibrium

at perfectly balanced ion flow. The ionizer is designed to

achieve balance under extreme conditions and is uniquely

able to maintain balance in almost any environment. Desco

ionizers meet the ANSI/ESD S20.20 less than ±50 volts

required limits offset voltage tested in accordance with

ANSI ESD S3.1. High Output Overhead Ionizers greatly

exceed the requirement providing ±15 volt auto balancing.

The unit’s circuitry also features a visual alarm, which alerts

the user of malfunction conditions caused by excessive

electrode contamination or the failure of either the

positive or negative power supply. When the High Output

Overhead Ionizer is ON and its output is balanced, the

blue LED indicator on the front of the unit will be steadily

lit. If a malfunction condition is detected the balance

circuit will cause the blue LED to flash until the problem is

corrected. See the maintenance section for recommended

maintenance procedures.

© 2013 DESCO INDUSTRIES INC.

Employee Owned

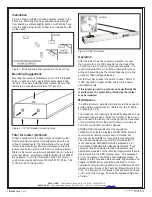

Figure 6. Cleaning the emitters and fan guards

Emitter pin cleaning is very simple and should be

done frequently. TURN THE IONIZER OFF. Blow off

contaminants on the emitter assemblies and fan guards with

clean dry air.

If the ionizer does not return to proper balance, then you

may need to clean each emitter point more thoroughly.

TURN THE UNIT OFF AND DISCONNECT THE POWER

CORD.

With a non-linting swab or small brush dipped in

isopropyl alcohol wipe each emitter needle thoroughly.

Brush off emitters to assure that stray filaments of cleaning

material are completely removed. A soft cloth and alcohol

may be used to clean each fan guard.

Emitter Needle Replacement

The tri-metallic emitters should not require replacement

unless broken or damaged. Contact Desco if replacement is

required.

Light Bulb Replacement

The High Output Overhead Ionizer features two fluorescent

light bulbs. They can be accessed and replaced by

removing the two covers located at the top of the ionizer.

The light bulbs should only be replaced by the same

compact fluorescent bulbs, 15 W max. NOTE: Never use

incandescent lamps in the High Output Overhead Ionizer.

Neutralization Efficiency (Discharge Times)

The comparative efficiency of overhead top ionizers is

determined by a standard test published by the ESD

Association Standard ANSI/ESD S3.1. The typical discharge

times measured using this standard for the ionizer are

shown in the following diagram. The performance of the

ionizer was measured with the unit positioned at varying

distances with the fan speed on high and without a filter.

DESCO IONIZER

Figure 7. Discharge times in seconds from ±1000 volts to

±100 volts on a 6" x 6" charged plate per ANSI/ESD S3.1

DESCO WEST

- 3651 Walnut Avenue, Chino, CA 91710 • (909) 627-8178

DESCO EAST

- One Colgate Way, Canton, MA 02021-1407 • (781) 821-8370 • Website: