Air ionization can neutralize the

static charge on insulated and

isolated objects by producing

separate charges in the molecules of

the gases of the surrounding air.

When an electrostatic charge is

present on objects in the work

environment, it will be neutralized

by attracting opposite polarity

charges from the ionized air. Note

that ionization systems should not be

used as a primary means of charge

control on conductors or people.

(Reference: IEC 61340-5-2:1

paragraph 5.2.9).

The Desco EMIT’s Critical

Environment overhead ionizers are

NIST calibrated and are available in

four models:

The 50606 and 50608 are 24" long

units with 2 fans, and the 50607 and

50609 are 48" long units with 4 fans.

All models have the same features

permitting the user to select the best

size for the application. Since our

introduction of the first overhead

ionizer in the market, we have

continued to enhance our offerings

with the most advanced features

available.

TB-6529

Page 2 of 9

Description

Ionizers are useful in preventing

electrostatic charge generation,

ElectroStatic Discharge,

ElectroStatic Attraction, as well as

preventing equipment latch-up and

safety related shock. ANSI/ESD

S20.20 Paragraph 6.2.3.1 Protected

Areas Requirement states:

"Ionization or other charge

mitigating techniques shall be used

at the workstation to neutralize

electrostatic fields on all process

essential insulators if the

electrostatic field is considered a

threat." Ionization is used to

neutralize charges on process

necessary insulators and isolated

semiconductors. Some examples of

process necessary insulators are: the

PC board itself, plastic test stands,

plastic housing where a PCB may be

mounted, as well as computer

monitor screens and regular cleaning

wipes. Examples of floating or

isolated conductors are: loaded PCB

mounted in a stand where the pins

are not contacting the dissipative

workstation. Ionization is not

effective on items that have large

capacitance, like people and carts;

however, ionizers should be

considered as a method for charge

neutralization in cases where

grounding cannot be achieved.

IONIZER SELECTION

ANSI/ESD S20.20 paragraph

6.1.1.2. ESD Control Program Plan

Guidance states: "The Plan should

include a listing of the specific type

of ESD protective materials and

equipment used in the Program."

When selecting an ionizer life cycle

costs should be considered

including: equipment cost;

installation cost; and operation and

maintenance cost.

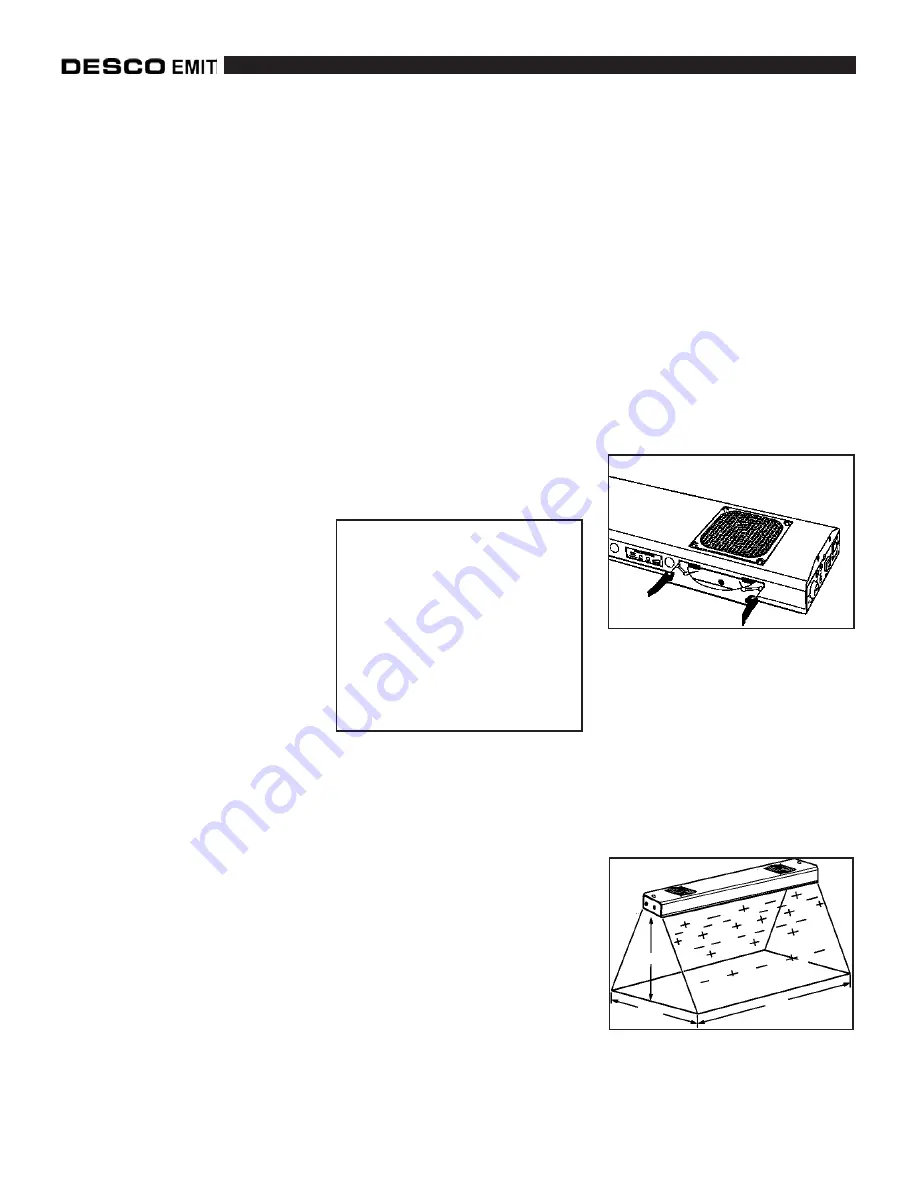

The C/E series offers many design

improvements, most notably, our

patent-pending “Emitter Cassette”

(see figure 1).

Figure 1. Removable emitter

cassette

While other manufacturers attempt

to simplify or automate the cleaning

of the emitter pins, what remains is

one major flaw in the process -

unless the ionizer is removed to

another area, the contamination ends

up on the workstation and on any

product that happens to be nearby.

Figure 2. Area of optimum charge

neutralization for 50606 and 50608

50606

C/E Ionizer 24", 120 Volt

50607

C/E Ionizer 48", 120 Volt

50608

C/E Ionizer 24", 220 Volt

50609

C/E Ionizer 48", 220 Volt

*U.S. Patent #6,137,670

24 IN.

24 IN.

30 IN.

OPTIMUM

PERFORMANCE ZONE

© 2007 DESCO INDUSTRIES INC.

Employee Owned