WARNING:

To use the capacity of the device optimally and to ensure its

failure-free functioning, please read carefully this operating

manual.

This equipment is not intended for use by persons (including

children) with a limited physical, sensual and psychical

abilities or by persons who are not experienced or familiar

with the equipment unless it is done under the supervision or

in accordance with the operating manual of the equipment

delivered by persons responsible for their safety. Pay

attention to children as they should not play with the

equipment.

If an undetachable power cable is damaged, it should be

replaced at the manufacturer or at the specialist repair works

or by a qualified person in order to avoid hazard.

INSTALLATION

Become familiar with the local regulations.

Place the furnace on a flat concrete ground.

Install the heat distributor with a conduit at the top of

the WA 33 B furnace.

Take all the furnace parts packed inside the

incineration chamber out.

Level the furnace. In order to check whether the

furnace is levelled, place the combustion dish (22) in

the bottom part of the incineration chamber and pour

out a small amount of fuel oil on it. The oil should be

spilled exactly in the middle of the plate.

Mount the air regulator on the pipe coming out of the

incineration chamber, in order to ensure a stable

draught during the use of the furnace.

In order to ensure optimal draught, install at east a 5-

metre long vertical chimney pipe resistant to high

temperature (not made of aluminium).

While installing the exhaust fume discharge system, it

is recommended to avoid the horizontal sections of the

chimney pipe. In order to ensure the free outflow of

gases, the angle of the possible pipe bend should not

be greater than maximum 45º.

Chimney outlet must be higher than the top of the roof.

WARNING:

The places at which the chimney pipe passes through the

ceiling, walls or the roof, must be insulated in order to avoid

the fire hazard. It is recommended to use the double-wall

insulated chimney pipe at all places where there is a

possibility of a contact by touch and outside the building in

order to ensure the permanent good run and prevent the

condensation. The air heater may not be connected to the

joint exhaust fume discharge system.

Check the tightness of all connections, if necessary,

tighten them with the insulation tape.

Make sure that the combustion dish is placed centrally

in the incineration chamber

Place the chamber disk (20) inside the combustion

chamber with the inset in the middle of the ring to the

top and mount the chamber pipe on it (17).

Check the mains voltage and connect the furnace to

power supply. Neither the fan nor the pump should be

switched on as the furnace is not switched on yet and

no heat has been produced.

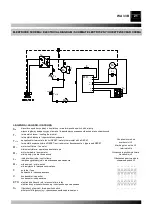

The device is equipped with a pump performance control

thermostat (T

V

) and an overheating thermostat (T

STB

).

WARNING:

Do not place any materials nearby the furnace, even the ones

that are not inflammable. Ensure permanent access of air

necessary for the proper incineration process.

Do not light the hot burner plate again.

Always wait until the burner plate is completely cooled off.

For the correct incineration process, ensure access of the

appropriate quantity of air

OPERATION OF THE FURNACE

The furnace may be operated with the use of various

types of oils (diesel oil, fuel oil, biodiesel oil, pure and

used engine oil, gear oil, hydraulic oil, plant oil etc.) You

must not apply transformer oils and nitro substances.

Two switches (49) and (67), a control lamp (68),

informing about the operation of the pump and the pump

motor fuse (72) are located on the control panel. The

switch (49) fulfils the function of the main power supply

switch. The switch (67) serves the purpose of changing

the heating efficiency and switching off the pump. In

position „I” the furnace operates with lower efficiency and

in position ”II” with greater efficiency.

The furnace has no protection from the extinguishment

of the flame at this moment; the pump will not stop

functioning and the oil may overflow. The overflow

protection will switch off the pump (the control lamp will

be switched off), but the fan (7) will still function. THE

FURNACE MUST COOL OFF, then the overflow

protection and the place under the burner plate must be

cleaned.

WARNING:

During the operation of the air heater, the temperature of

respective parts is high, therefore it is necessary to maintain all

the necessary precautions.

RECOMMENDATION:

Use switch (49) during problems with starting the

furnace. In the initial stage of starting the furnace,

leave switch (49) for 20-30 minutes in position ”0”,

and then continue the activities according to the

manual for starting the furnace.

Pump motor (52) drives the pump which is located

inside the tank and overflows the oil through the fuel

supply set (61) onto the combustion dish (22).

After the furnace is lighted, it should operate with a

smaller efficiency for about 20 minutes in order to

produce the appropriate temperature for operation

with higher efficiency.

WARNING:

Do not pull out the plug from the electrical socket, before the

motor cools off completely.

6

WA 33 B

Содержание Master WA 33 B

Страница 23: ...WA 33 B WA 33 B 23 ...