www.delta-controls.com

IOM-GR-A : AUGUST 2016

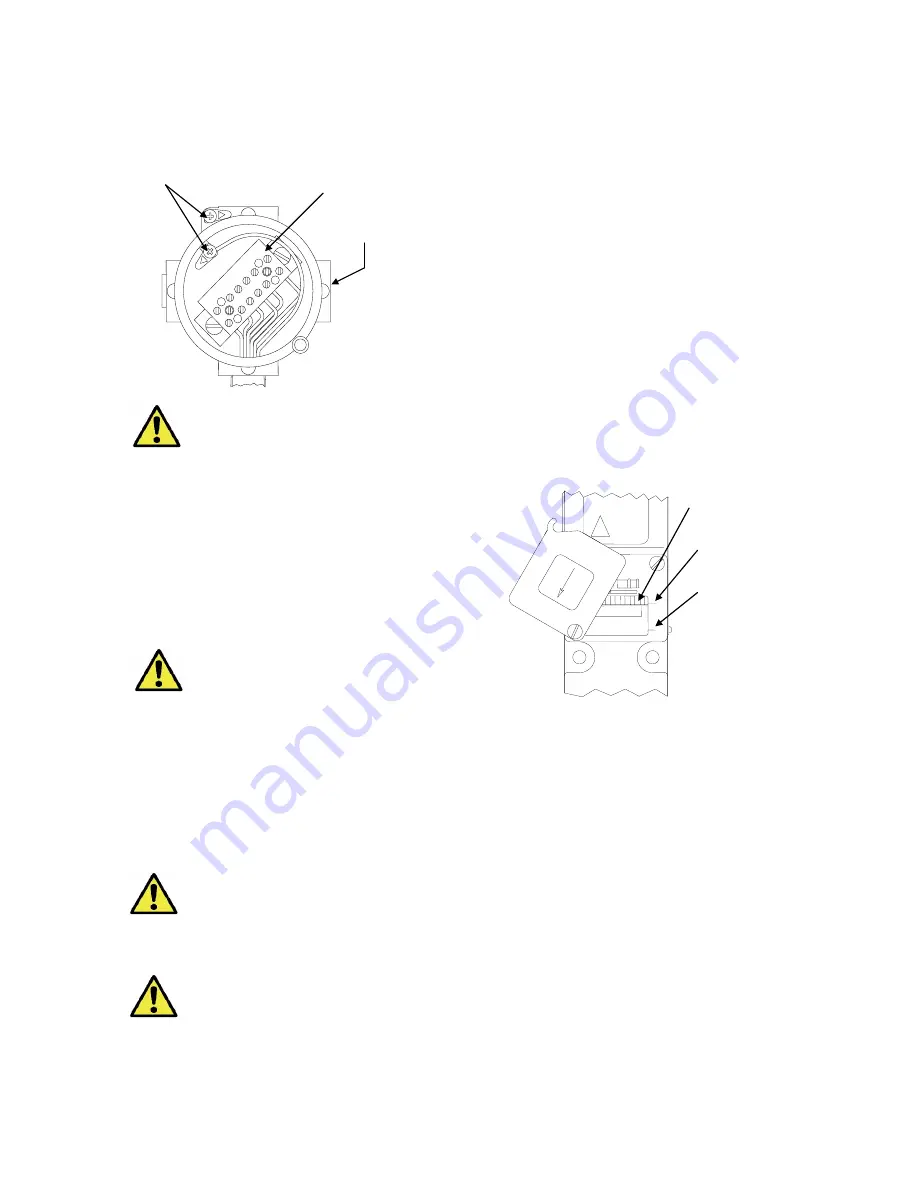

Wiring - when Junction Box is fitted

(See Fig. 4)

Some models may be provided with an integral

weatherproof or Ex junction box.

WIRE IN ACCORDANCE WITH LOCAL

AND NATIONAL CODES. USE CABLES

NO LARGER THAN 2.5 MM² (14 AWG)

Insert bare wires fully into the terminal block and

tighten securely. Keep wiring tails to a minimum.

End of line resistors

Some products may be supplied to order fitted with

end of line resistors. Resistors in use may generate

a heat source. The type, quantity, configuration,

fitment method and allowable electrical loads are

limited by the scope of the certification.

NEVER FIT END OF LINE RESISTORS OR

MODIFY WITHOUT REFERENCE TO

DELTA CONTROLS

Replacing

cover

on

Flameproof

enclosures

Before connecting to electrical power, screw on

cover hand tight making sure that mating surfaces of

the lid and enclosure are in contact. Use the locking

screws provided to prevent casual and unauthorised

removal of the cover.

DO

NOT

USE

GREASES

OR

LUBRICANTS NOT COMPATIBLE WITH

THE

ENVIROMENT,

PROCESS

OR

ALUMINIUM.

IT IS A SAFETY REQUIREMENT THAT AT

LEAST 5 FULL THREADS ARE ENGAGED

BETWEEN THE COVER / LID AND THE

ENCLOSURE WHEN THE UNIT IS IN

OPERATION. NEVER OPERATE THE

UNIT UNLESS THIS CONDITION IS MET.

OPERATION

Adjustments

Pressure and Temperature Switches are supplied

calibrated at the midpoint of their range and to a

falling pressure or temperature unless otherwise

specified.

Set point adjustments (All Models)

:

(See Fig. 5)

1. Isolate the instrument from process and power

(Adjustment may be carried out with the unit live)

2. Loosen both cover screws

3. Rotate cover anti-clockwise to allow access.

4. Using a screwdriver, rotate the range adjuster to

obtain the desire setting. Turn right to left to

increase the setting. An appropriate setting is

shown by pointer against reference scale.

5. Rotate cover clockwise to close and tighten

screws.

As a guide, one complete revolution of the adjuster

will alter the set point by approximately 15% of the

range.

Note:

For accurate setting of Pressure and

Differential Pressure models, a suitable pressure

gauge must be used in conjunction with the above

procedure. Do not attempt to set the switch outside

the scale limits. For Temperature models a suitable

calibrated temperature source should be used.

Though the unit may be set anywhere within its

range, for optimum performance, it is good practice

to have a set point value between 25% and 75% of

span.

Process configurations (Models GR3,

GR6 - other than range BC)

For normal pressure difference operation, the

connections are made to the High Pressure (HP)

and Low Pressure (LP) ports as appropriate. For

single-ended positive pressure operation, the HP

only is used and the LP is left open to atmosphere.

The single-ended negative pressure operation, the

LP only is used and the HP is left open to

atmosphere.

Use a breather / filter in the vacant port of single-

ended operation.

SCREW DRIVER

LOCATION SLOTS

LOWEST SET POINT

HIGHEST SET POINT

ADJUST RIGHT TO

LEFT TO INCREASE

SET POINT

Fig 3

ATEX

ATEX

Fig 5

ATEX

ATEX

NC

COM

NO

NC

COM

NO

EARTH SCREW

TERMINAL BLOCK

NORMAL R H

ELECTRICAL ENTRY

Fig 2

Fig 4