-

11

-

3. Assembly SOP

Preparation before assemble

1. Clean the room for work

2. Identify the area for material

3. Prepare the implement, equipment, material as bellow:

1) Working table

2) Screw-driver

3) Glove

4) Cleaning cloth

ESD protection

Item

Picture

Operation

Tools

Notes

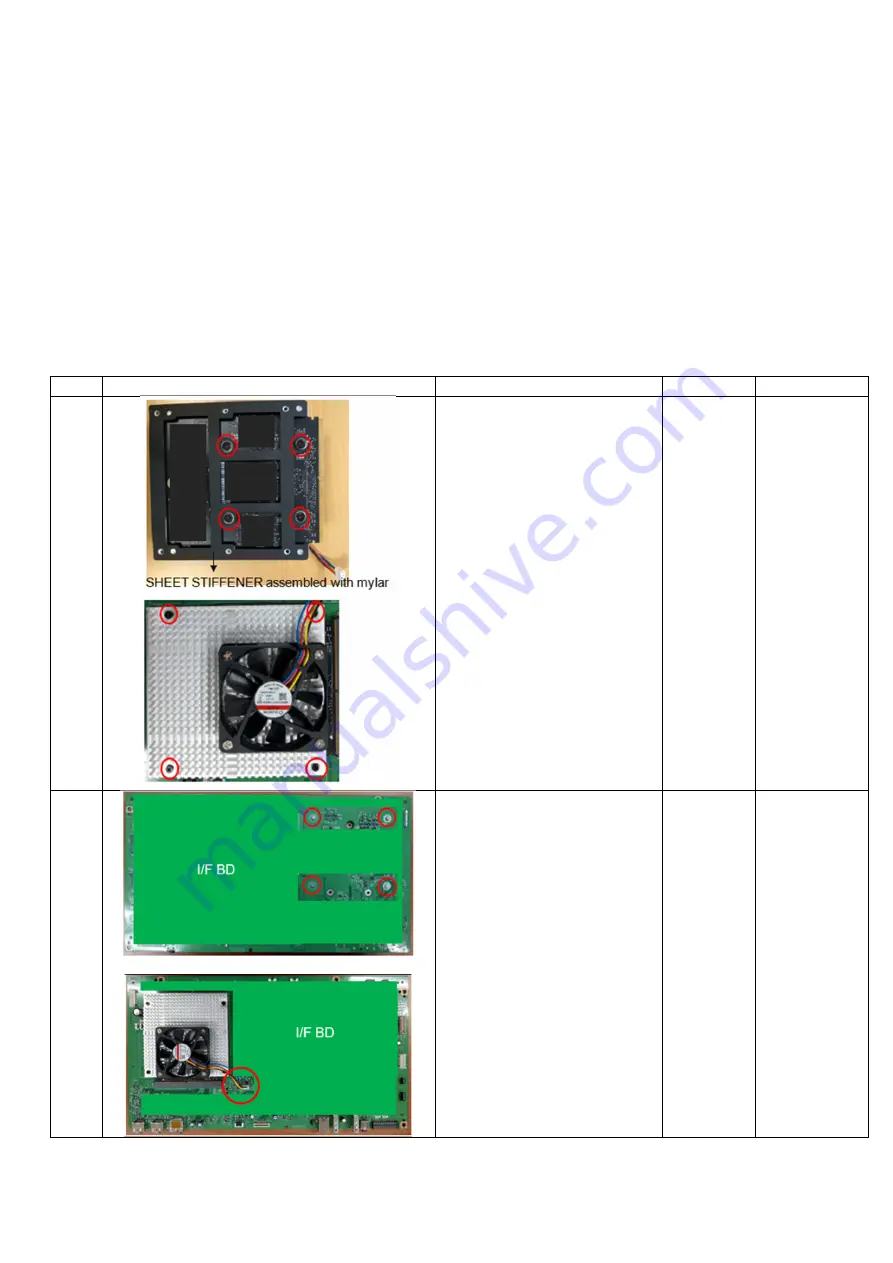

1

1. Assemble MYLAR with

SHEET STIFFENER

2. Assemble G-Sync

module, Heat Sink

Module and SHEET

STIFFENER, then, fix

them by captive screw*4

3. Lock 4 Heat Sink Screws

Screw

driver

(Screw

Torque-

Captive

Screw:

2-

2.5

kgf)

S

crew

Torque-

Heat Sink:

4-4.5 kgf)

2

1. Assemble G-SYNC

Module with I/F BD and

fix it by screw*4

2. Insert Fan Cable into I/F

BD

Screw

driver

(S

crew

Torque: 4-

4.5 kgf)