DATAPROCESS EUROPE S.p.A.

ST 230 USER MANUAL Pag.

44

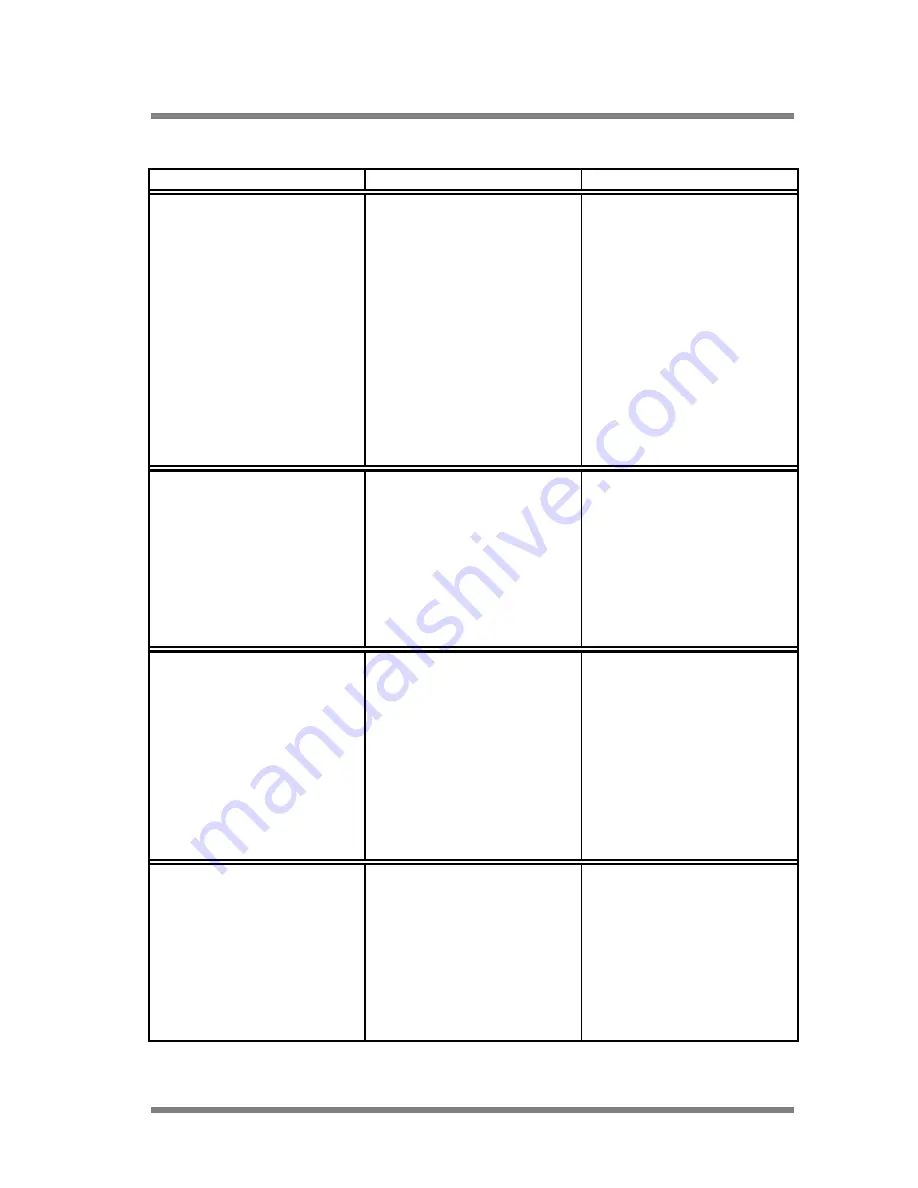

SYMPTOM

POSSIBLE CAUSE

ACTION

THE PAPER IS FED BUT NOT

PRINTED

.

Printhead lifted (printer with

rewinder).

Printhead connection (flat cable).

Faulty printhead

Improper inked ribbon or

incorrectly mounted

Internal trouble

Lower in printing position

Verify the correct insertion

of the flat cable into the con-

nector located at the back of the

printhead.

Replace it or contact Technical

Assistance.

Replace it with a recommended

type or reinstall it correctly.

Contact Technical Assistance.

IRREGULAR PAPER FEED

Dirty rubber roll, damaged or

worn

.

Paper path not correct.

Jammed labels.

Clean it with a solvent or

contact

Technical Assistance.

Verify the correct installation

of the labels roll.

Remove and clean all the

glue residue with a proper

solvent.

POOR PRINT QUALITY

(UNIFORMLY)

Improper paper and or ribbon

Wrong configuration (speed-

temperature).

Insufficient pressure of print-

head on the paper.

Used printhead

Replace with recommended type.

Configure again using correct

parameter value.

Verify the print by pressing on the

printhead and eventually contact

Technical Assistance.

Replace it or contact Technical

Assistance.

POOR PRINT QUALITY (ONLY ON

STRIPS PARALLEL TO THE

FEEDING DIRECTION)

Dirty printhead

Used printhead

Dirty rubber roll, used or

damaged.

Clean with proper solvent

Replace it or contact Technical

Assistance.

Clean with proper solvent or

contact Technical Assistance