7

H)

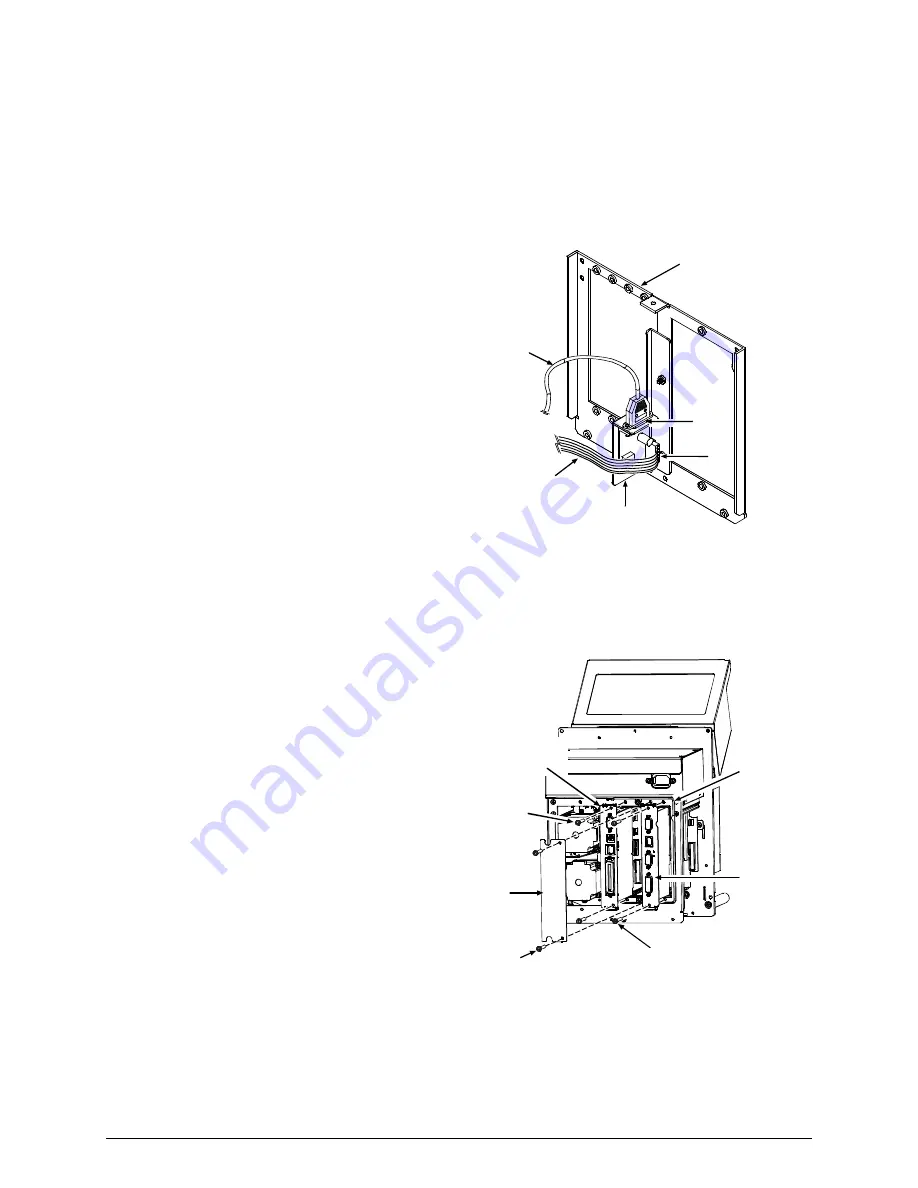

Connect and secure the

Interface Cable

to

J2

on the

Cutter CCA

, and connect the

Control Cable

to

J1

.

Interface

Cable

Cutter

CCA

Control

Cable

J2

J1

Rear Bracket

I)

Replace the

Card Cage

items:

Replace

the

Main Logic CCA

then secure

it using the two

Main Logic CCA Screws

;

Replace

the

Applicator Interface CCA

then secure it using the two

Applicator

Interface CCA Screws

; and,

Replace

the

Card Cage Cover

then

secure it using the two

Card Cage Cover

Screws

.

Card

Cage

Applicator

Interface

CCA

Main Logic

CCA Screws

(2 places)

Applicator Interface

CCA Screws

(2 places)

Card

Cage Cover

Card Cage

Cover Screws

(2 places)

Main Logic

CCA

Содержание A Class Mark II

Страница 1: ...92 2534 01 Rev A Cutter Option Installation Instructions ...

Страница 2: ......