11

Step 4: Configuring the Printer

While the Cutter option is a plug and play device, this step may be necessary if the printer’s default

configuration has been changed. Follow the steps below (or consult the

Operator’s Manual,

if necessary

)

to configure the printer:

A)

Press the

MENU Key

on the printer’s front panel.

B)

Using the

↓

Key

, scroll to

PRINTER OPTIONS

then press the

ENTER Key.

C)

Using

the

↓

Key

, scroll to

CUTTER

then press the

ENTER Key

.

D)

Using the

↓

Key

,

scroll to

AUTO

then press the

ENTER Key

.

E)

Press

the

ESC Key

then, at the

SAVE CHANGES?

prompt, select

YES

.

F)

Turn

the

Power Switch

‘Off’ and ‘On’ to reset the printer and complete the configuration.

;

Note:

The operation of the

Cutter can also be controlled by host software commands, so ensure that

your labeling program is properly configured for use, and for cutting labels to the desired size.

To test the Cutter’s operation, see “Testing the Cutter” (near the end of this document).

Maintaining the Cutter

To ensure trouble free operation, the Cutter should be cleaned after printing each roll of labels.

Additionally, if the cutting action becomes sluggish, immediate cleaning is recommended. Clean the

Cutter as follows:

CAUTION

Cutter Blades are SHARP: Keep body parts away from the cutting surfaces. Never use

metal objects on the cutting surfaces. Take proper precautions when using isopropyl

alcohol, a flammable liquid.

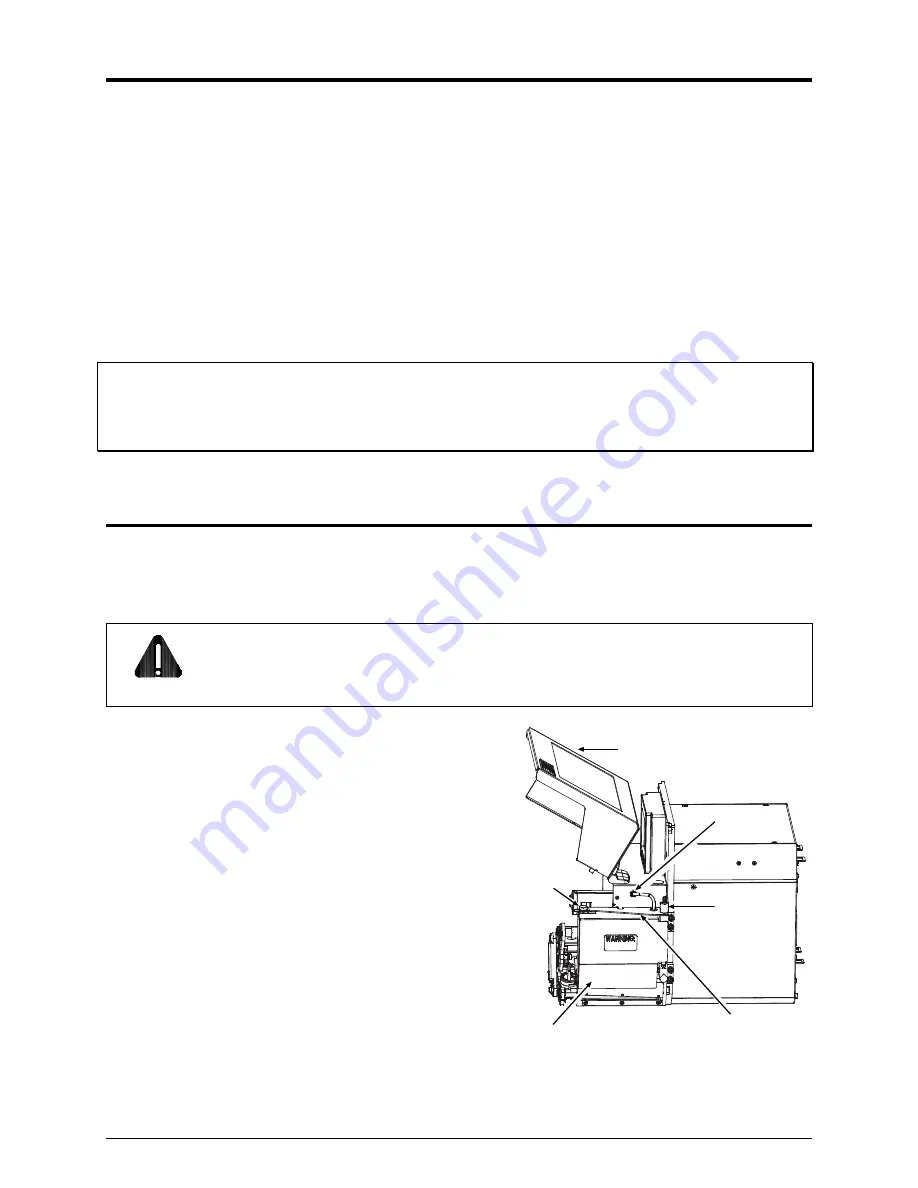

1)

Turn ‘Off’ the Power Switch and unplug the power

cord from the AC Receptacle. Raise the

Access

Cover

then remove the media from the printer.

2)

Unplug the

Cutter Cable

. Remove the

Thumbscrew

and the

Vertical Mounting Screw

,

and then

remove the

Cutter Assembly

from the

Mount

.

Thumbscrew

Cutter

Assembly

Access Cover

Mount

Vertical

Mounting

Screw

Cutter

Cable

Содержание A Class Mark II

Страница 1: ...92 2534 01 Rev A Cutter Option Installation Instructions ...

Страница 2: ......