B-2

Printer Specifications

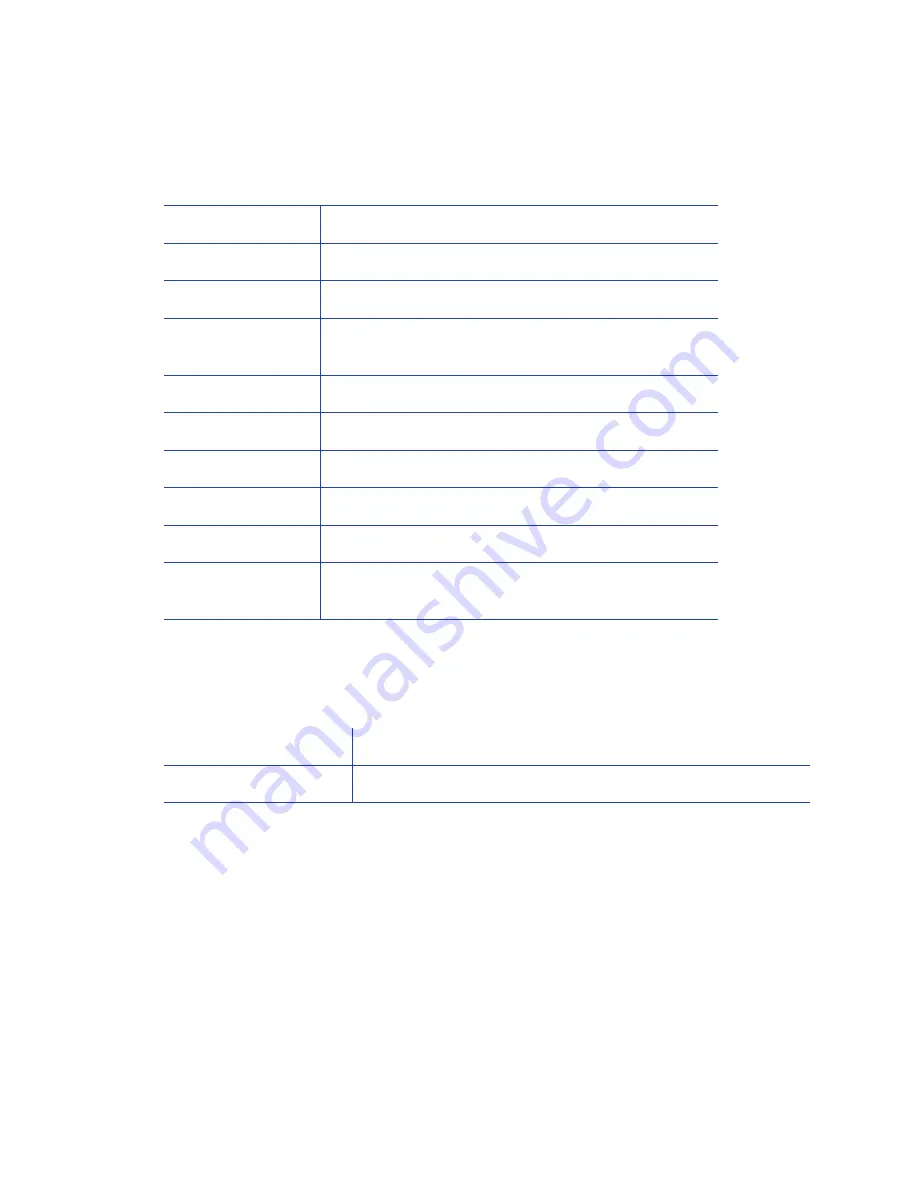

Operating Specifications

The CR500 printer operates under the following specifications.

Operating Environment

Use the following environment guidelines when operating the printer.

Recording method

Dye sublimation retransfer

Feed format

Automatic feed

Recording density

300 dpi

Reproduction

gradations

256 levels each yellow (Y), magenta (M), and cyan (C);

two for black (K)

Printing time

29 seconds (single-sided, excluding data transfer time)

Interface

Ethernet (100Base-Tx or 10Base-T)

Power supply (2)

100–120VAC or 220–240VAC (±10%)

Current dissipation

3.5A for 100V system and 1.6A for 200V system

Weight

47 lbs (21.3 kg)

Sound level

Less than 70dB(A) according to DIN45635, part 19

(EN27779)

Operating temperature

63°–83°F (17°–28°C)

Operating humidity

35%–60%, non-condensing

Содержание CR500

Страница 8: ...viii ...

Страница 10: ...x ...

Страница 14: ...xiv ...

Страница 20: ...6 Introduction ...

Страница 28: ...14 Plan the Installation ...

Страница 60: ...46 Install the Printer ...

Страница 106: ...B 4 Printer Specifications ...