Application guidelines

58

FRCC.PC.023.A7.22

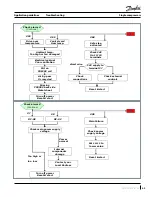

Single compressors

Installation

Mounting

Removing connections

shipping plugs

Maximum inclination from the vertical plane

while operating must not exceed 3 degrees.

VZH compressors come delivered with four

rubber mounting grommets and metal sleeve

liners that serve to isolate the compressor from

the base frame. These grommets must always

be used to mount the compressor in a single

application. The grommets must be compressed

until contact between the flat washer and

the steel mounting sleeve is established. The

grommets attenuate to a great extent the

transmission of compressor vibrations to the base

frame.

Before the suction and discharge plugs are

removed, the nitrogen holding charge must be

released via the suction schrader valve to avoid

an oil mist blowout. Remove the suction plug

first and the discharge plug afterwards. The plugs

shall be removed only just before connecting the

compressor to the installation in order to avoid

moisture from entering the compressor. When

the plugs are removed, it is essential to keep the

compressor in an upright position so as to avoid

oil spillage.

Each VZH scroll compressor is equipped with

two lift rings on the top shell. Always use

both these rings when lifting the compressor.

Use lifting equipment rated and certified for

the weight of the compressor. A spreader

bar rated for the weight of the compressor is

highly recommended to ensure a better load

distribution. The use of lifting hooks closed with a

clasp certified to lift the weight of the compressor

is also highly recommended. Always respect the

appropriate rules concerning lifting objects of the

type and weight of these compressors. Maintain

the compressor in an upright position during all

handling operations.

Never use only one lifting lug to lift the

compressor. The compressor is too heavy for

the single lug to handle, and the risk is that the

lug could separate from the compressor with

extensive damage and possible personal injury

as a result.

When the compressor is mounted as part of

an installation, never use the lift rings on the

compressor to lift the installation. The risk is that

the lugs could separate from the compressor

or that the compressor could separate from the

base frame with extensive damage and possible

personal injury as a result.

Never apply force to the terminal box with the

intention of moving the compressor, as the

force placed upon the terminal box can cause

extensive damage to both the box and the

components contained inside.

Compressor handling

0.59 inch

HM 8 bolt

Lock washer

Flat washer

Steel mounting

sleeve

Rubber grommet

Nut

HEAVY

do not lift

manually

The required bolt size for VZH170 compressors is

HM8-55 and must be tightened to a torque of 15

ft/lbs.

HM 8 bolt

Lock washer

Flat washer

Steel mounting sleeve

Rubber grommet

Nut

1.10 inch

Compressor

base plate

The required bolt size for the VZH088 & 117

compressors is HM8-40. This bolt must be

tightened to a torque of 11 ft/lbs.

Each compressor is shipped with printed

instructions for installation. These instructions

can also be downloaded from:

http://instructions.cc.danfoss.com