VLT® 4000 VT

■

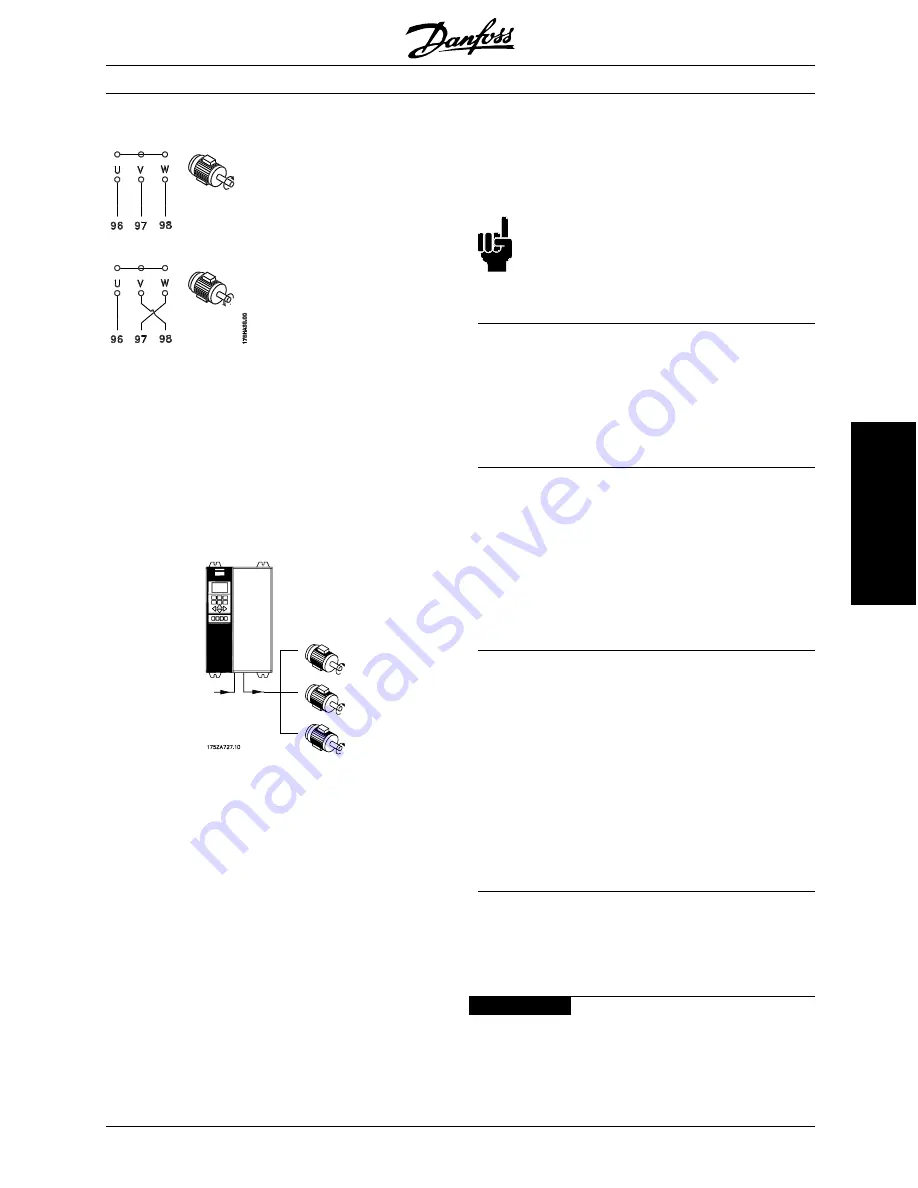

Direction of IEC motor rotation

The factory setting is for clockwise rotationwith the VLT

frequency transformer output connected as follows.

Terminal 96 connected to U-phase

Terminal 97 connected to V-phase

Terminal 98 connected to W-phase

The direction of rotation can be changed by switching

two phases in the motor cable.

■

Parallel coupling of motors

VLT 4000 VT is able to control several motors

connected in parallel. If the motors are to have

diffe-rent rpm values, the motors must have

different rated rpm values. Motor rpm is changed

simultaneously, which means that the ratio between

the rated rpm values is maintained across the range.

The total current consumption of the motors

is not to exceed the maximum rated output

current I

VLT,N

for the VLT AFD.

Problems may arise at the start and at low rpm values if

the motor sizes are widely different. This is because the

relatively high ohmic resistance in small motors calls for

a higher voltage at the start and at low rpm values.

In systems with motors connected in parallel, the

electronic thermal relay (ETR) of the VLT AFD cannot

be used as motor protection for the individual

motor. Consequently, additional motor protection

is required, such as thermistors in ground motor

(or individual thermal relays).

NOTE

Parameter 107

Automatic Motor Adaptation,

AMA

and

Automatic Energy Optimization, AEO

in parameter 101

Torque characteristics

cannot

be used motors are connected in parallel.

■

Motor cables

See

Technical data

for correct sizing of motor

cable cross-section and length.

Always comply with national and local regulations

on cable cross-sections.

■

Motor thermal protection

The electronic thermal relay in UL-approved AFD has

received UL-approval for single motor protection, as

long as parameter 117

Motor thermal protection

has

been set to ETR Trip and parameter 105

Motor current,

I

VLT,N

has been programmed for the rated motor current

(can be read from the motor nameplate).

■

Ground connection

Since the leakage currents to ground may be higher

than 3.5 mA, the AFD must always be grounded

in accordance with applicable national and local

regulations. In order to ensure good mechanical

connection of the ground cable, its cable cross-section

must be at least 8 AWG/10 mm

2

. For added

security, an RCD (Residual Current Device) may be

installed. This ensures that the AFD will cut out

if the leakage currents get too high.

■

Installation of 24 Volt external DC supply:

Torque: 0.5 - 0.6 Nm

Screw size: M3

No.

Function

35 (-), 36 (+)

24 V external DC supply

24 V external DC supply can be used as low-voltage

supply to the control card and any option cards

installed. This enables full operation of the LCP (incl.

MG.40.A4.22 - VLT is a registered Danfoss trademark

47

Installation