AK-PC

551

User

Guide RS8GY302 © Danfoss 2015-06

9

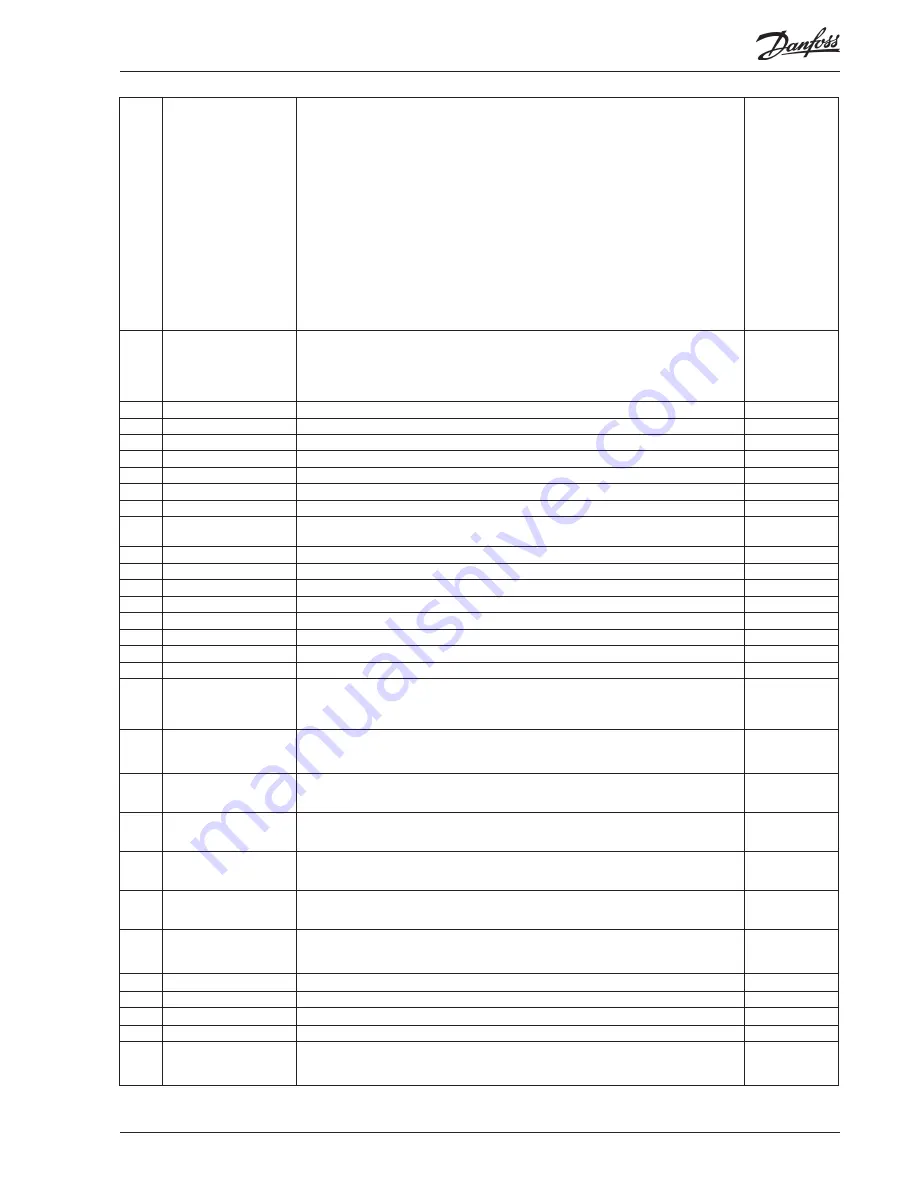

Control status

Read the status of the control circuit here e.g.:

• No comp. - No compressor capacity available

• Normal ctrl - Normal control

• Alarm Comp. - Cannot start compressor due to alarm condition

• ON timer - Cannot stop compressor due to ON timer restriction

• Start timer - Cannot start compressor due to Start timer restriction

• Normal ctrl - Normal control - no compressor staging

• Inj. On Delay - Waiting for injection on delay to expire

• Cascade

• 1st comp del - First compressor run timer

• Pump down - Last compressor running to pump down limit

• Sensor error - Emergency control due to sensor error

• Load shed - Load shedding function active

• Sd High - Capacity control in High Sd safety prevention mode

• Pc High - Capacity control in High Pc safety prevention mode

• Manual ctrl - Capacity control in manual mode

• Main switch OFF - OFF

Actuel zone

You will be able to see how the regulation is in relation to the reference here:

P0 error: No regulation

- Zone: The desired pressure is below the reference value

NZ: The pressure is in place in relation to the reference value

+ Zone: The desired pressure is above the reference value

Control temp.

The current value of the regulation sensor can be read here

Reference

The total regulation reference can be read here

Running capacity

Here the connected capacity can be read as a % of total capacity

Requested capacity

Here the preferred connected capacity can be read as a % of total capacity

No. of running comp.

The number of compressors in operation can be read here

PoA Pressure

The measured pressure for the PoA pressure transmitter can be read here

ToA Saturated temp.

The measured PoA pressure converted to temperature can be read here

MC PoA offset

The size of a reference displacement on Po required from the system unit

(suction pressure optimisation function) can be read here

Pc Pressure

The measured pressure for pressure transmitter Pc can be read here

Tc Saturated temp.

The measured Pc pressure converted to temperature can be read here

Day / Night status

The status of the day/night function can be read here

Load shed

The status of the load shed function can be read here

Injection ON A

The status of the injection ON signal sent to the evaporator controllers can be read here

MC Load Shedding

The status of the load shed signal received from the system device can be read here

MC Night Setback

The status of the night increase signal received from the system device can be read here

Control settings

Regulation settings

Control mode

Regulation type

The regulation is normally set to “Auto”, but it can be changed to “Off” or “Manual”.

When setting to “Manual”, a forced capacity setting can subsequently be entered in %.

MAN / OFF / AUTO

Fac: AUTO

Min: 0 %

Max: 100%

Setpoint

Enter the set point for the regulation (regulation reference = set point + different offsets) here

An offset can originate from a night increase signal or from an override function on the

system device.

Min: -80°C (-1.0 bar)

Max: 30°C (50 bar)

Fac: -15°C (3.5 bar)

Neutral zone

Set the neutral zone around the reference here. Also see the illustration on page 3.

Min: 0,1 K (0.1 bar)

Max: 20 K (5.0 bar)

Fac: 6 K (0.4 bar)

Night offset

If necessary, set the value by which the reference will be raised at night.

Keep the setting at 0 if regulating with Po optimisation from a system device.

Min: -25 K (-5.0 bar)

Max: 25 K (5.0 bar)

Fac: 0 K (0.0 bar)

Max Reference

Set the highest permissible regulation reference here

Min: -50°C (-1.0 bar)

Max: 80°C (50.0 bar)

Fac: 80°C (40.0 bar)

Min Reference

Set the lowest permissible regulation reference here

Min: -80°C (-1.0 bar)

Max: 25°C (40.0 bar)

Fac: -80°C (-1.0 bar)

PI control selection

Set how quickly the PI regulation must react here: 1 = slowly, 10 = very quickly.

(For “Custom” setting 0, the special settings options will open, i.e. Kp, Tn and time settings

around the neutral zone. These options are only for trained staff.)

Min: 0 (custom)

Max: 10

Fac: 5

Gain factor Kp

The amplification factor, Kp (can only be seen and set when the previous menu is set to “0”)

Integration time Tn

Integration time Tn (see above)

+ Zone rate of change Change coefficient for + zone (see above)

- Zone rate of change Change coefficient for - zone (see above)

First step runtime

At start-up, the cooling system must have time to cool down before PI regulation takes over

the regulation role and can cut in the next compressor.

Set the time before the next compressor may be started here.

Min: 0 s

Max: 300 s

Fac: 120 s