32

Wheel Differential

Wheel Differential

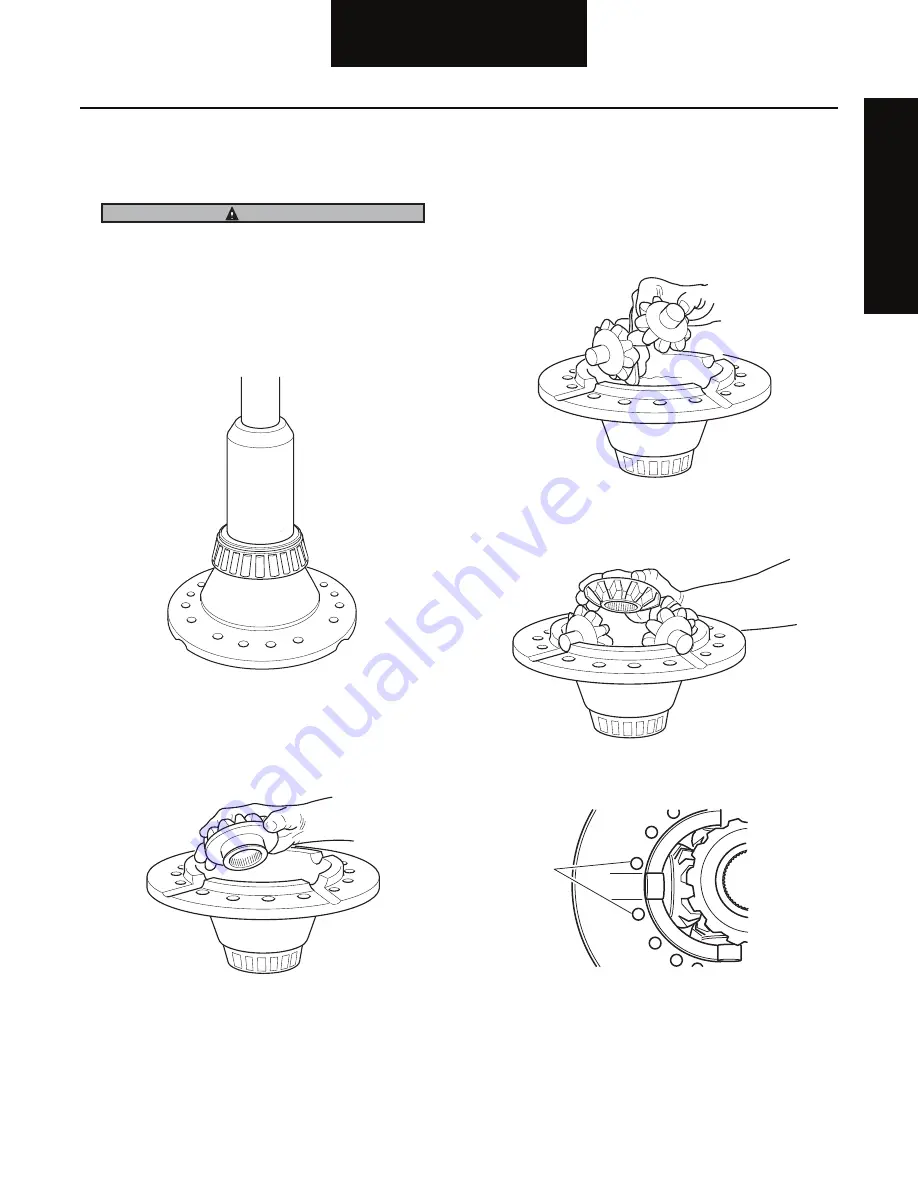

Wheel Differential Assembly - Forward Carrier Assembly

To prevent bearing damage, use suitable sleeve that only

contacts the inner race of the cone. A used bearing race

would be a suitable tool. This tool should have a slit cut if

the ID is the same as the flange OD.

1. Press the new bearing cone on the plain half and

flange half bearing boss using the proper press

sleeve or bearing installation tool.

2. Place the plain half side of the differential case on a

malleable surface.

4. Assemble the side pinions and thrust washers

onto the wheel differential spider. Apply a thin

coat of oil to the mating surfaces of the side

pinion and differential spider. Install the

wheel differential nest on top of the side gear

5. Install the flange half side gear and thrust washer.

Apply a thin coat of oil to the mating surfaces.

6. Install the ring gear. Align the capscrew holes.

IMPORTANT

1 - Match spacing of holes on each side of

spider slots

3. Install the side gear and thrust washer. Apply a thin

coat of oil to the mating surfaces of the side gear

thrust washer and plain half.

1