370 S 370 S L 370 PP 370 PP L

36

Vise Gib Adjustment

370 PP / S

check

as needed

Way Oiler

370 PP / S

2 pumps

check / add

DRO Magnetic Strip

370 PP

wipe / clean

DRO Reader Adjustment

370 PP

check / set if needed

Lube Types

Head Feed Cylinder.-DTE 24

Hydraulic Oil

Spindle Grease -Hi Temp.

Way Oiler-Light Weight Way Oil

Air Oiler - Tool Oil

Clean DRO Strip-Clean Dry Rag

TROUBLSHOOTING GUIDE

FERROUS & NON-FERROUS HEAD

PROBLEM

THINGS TO CHECK

SOLUTION

Blade chatters while cutting

Blade pitch, gullets are packed

Replace blade, regrind, clean gullets

Part moves while cutting

Check how parts are clamped, rear vise Reclamp or fixture as needed

Par has hanging burr

Part distorted while clamped, anti burr

vise

Adjust anti burr arm or outboard vise

Part has burr on exit of cut

Lack of support on short pieces

Add solid wear plate to support part

Rough or scored finish

Blade dull, incorrect blade, tooth

missing

Replace blade, Reclamp part

Blade Breaks

Backlash, dull blade, part moved in

vise

Replace blade, Reclamp part

Motor/Gear box noise

Low oil, excessive backlash

Add oil, adjust backlash

Head is jerky

Binding components, air in system

If oil is full, bleed head cylinder

Motor hums or runs slow

Check Power source fuses, hood

interlock

Replace fuses, close hood

Motor runs backwards

Leads on incoming power are incorrect Have qualified electrician make a

change

No power to the machine

Check power source fuses, hood

interlock

Replace fuses, close hood

Vises do not operate or are slow

Incoming air pressure, regulator

pressure

Increase air pressure, set higher

Head stops down feeding

Lack of air, flow control valve

adjustment

Increase air pressure, adjust valve

Head returns slow

Gib strip adjustment, air return valve

closed

Adjust gib, open-air return valve more

Tolerances slipping

Feeder too fast, blade, overfeeding

Slow feeder, adjust blade thickness

Unsquare cutting

Wrong, dull blade thickness

adjustment

Slow feeder, adjust blade thickness

Will not feed material (370PP)

Multiple stroke counter, vise position

reversed

Multiple stroke set at 0, switch forward

Motor runs hot

Incoming voltage too high

Power should be +/- 10%

Head crashes down

Low or no oil in head feed cylinder

leakage

Add oil to cylinder as outlined repair

leak

Machine stops (370PP)

Blade protection stops operation

Correct problem and reset calibration

unit

Machine will not restart

Security locked out, piece counter not

cleared

Turn key to on position, clear counter

Machine will not start

E-stop activated, out of stock

Reset E-stop, check feed vise clearance

* Parts may come off hot, this is normal with non-ferrous cutting.

Содержание Euromatic 370 PP

Страница 9: ...370 S 370 S L 370 PP 370 PP L 9 ...

Страница 10: ...370 S 370 S L 370 PP 370 PP L 10 Actual control panel layout may vari ...

Страница 32: ...370 S 370 S L 370 PP 370 PP L 32 ...

Страница 33: ...370 S 370 S L 370 PP 370 PP L 33 ...

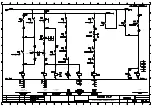

Страница 38: ...ALIMENTAZIONE 230V 60Hz 230V 60Hz POWER SUPPLY POWER SUPPLY ...

Страница 39: ...HL4 ILLUMINAZIONE LAMA POWER SUPPLY ...

Страница 40: ...LAMPEGGIATORE LAMA IN MOTO 24VAC MORSA 24VAC EMERGENCIES ...

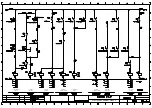

Страница 41: ...DISCESA TESTA EV DISCESA TESTA START MEMORIA PULSANTE CICLO SB4 START CICLO ELECTROMECHANICALCIRCUIT ...

Страница 44: ...9 11 2 4 5 10 3 6 7 8 1 CH1 LC4HR424ACJ KA5 RITORNO CARRO COUNTER ...

Страница 45: ...TERMINAL ...

Страница 49: ...10 2 2019 Euromatic 370 2 Head Cylinder Unit Ref 005 ...

Страница 51: ...10 2 2019 Euromatic 370 4 Bedplate Unit Ref 008 ...

Страница 53: ...10 2 2019 Euromatic 370 6 Head Unit Ref 002 ...

Страница 55: ...10 2 2019 Euromatic 370 8 Vise Unit Ref 004 ...

Страница 57: ...10 2 2019 Euromatic 370 10 Group Feeder P R ...

Страница 59: ...10 2 2019 Euromatic 370 12 Group Alimentador P P Ref 014b Alimentador Ref 014b ...