Installation and operation manual

9

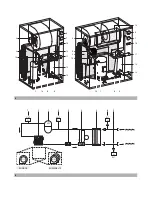

EUWAC5~10FZ

Packaged air-cooled water chillers

4PW14037-1D

Water leaks

Check the evaporator and the external water circuit on water

leaks.

Drain disposal

Put the service covers in place so that the unit is completely

closed, and start up the unit. After a few hours of operation,

check if the condensing water is evacuated properly through the

drain and that it does not flow over from the drain pan on the

floor.

It may happen that the drain pan outlet is obstructed or that the

condenser fans create a vacuum so that the condensing water

remains in the drain pan and flows over. In this case, the drain

disposal should be lowered. The level difference of 75 mm

indicated in the chapter “

” is a minimum.

3

If the unit does not start after a few minutes, consult the actual

operational information available in the list of direct parameters.

Also refer to the chapter

Switching the EUWAC unit off

To switch the EUWAC unit off, proceed as follows:

1

When the on/off digital input user parameter

h7

is set to

0

(=No)

and the unit is on, press the

I

key for approximately 5 seconds

to switch the unit off.

The

I

LED and the

T

LED are extinguished.

2

When the on/off digital input user parameter

h7

is set to

1

(=Yes), switch the unit off using the remote on/off switch or the

I

key.

The

I

LED and the

T

LED are extinguished.

Adjusting the cooling temperature setpoint

The EUWAC units enable definition and modification of the cooling

temperature setpoint. The default, limit and step values for the cool-

ing setpoint are:

■

Default value

12

.

0

°C

■

Limit values

7

.

0

to

25

.

0

°C

■

Step value

0

.

1

°C

To adjust the cooling temperature setpoint, proceed as follows:

1

Press the

R

key for approximately 5 seconds to enter the list of

direct parameters.

The direct parameter code

r1

defining the cooling temperature

setpoint appears on the display.

2

Press the

R

key.

The actual cooling temperature setpoint appears on the display.

3

Press the

A

or

Z

key to raise, respectively lower the

temperature setting.

4

Press the

R

key to return to parameter code

r1

.

5

To save the adjusted temperature setpoint, press the

E

key. To

cancel the modification wait approximately 40 seconds.

In the first case, the controller saves the changes, leaves the list

of direct parameters and returns to its normal operation,

displaying the inlet water temperature.

In the second case the display starts flashing. Approximately

40

seconds later, the controller leaves the list of direct

parameters without saving the modified parameter. The inlet

water temperature reappears on the display.

Consulting actual operational information

The actual operational information that can be consulted in the list of

direct parameters consists of:

■

r6

: outlet water temperature,

■

c9

: total running hours of the compressor,

■

cv

: total running hours of the pump.

To consult the actual operational information, proceed as follows:

1

Press the

R

key for approximately 5 seconds to enter the list of

direct parameters.

The direct parameter code

r1

defining the cooling temperature

setpoint appears on the display.

2

Depending on the information to be consulted, select parameter

code

r6

,

c9

or

cv

using the

A

and/or

Z

key.

3

Press the

R

key to consult the actual value of the selected

parameter.

4

Press the

R

key to return to the parameter codes.

5

To consult other actual operational information, repeat from

instruction 2 onwards.

6

To return to normal operation, press the

E

key or wait

approximately 40 seconds.

In the first case, the controller immediately leaves the list of

direct parameters and returns to normal operation displaying the

inlet water temperature.

In the second case, the display will start flashing. Approximately

40 seconds later, the controller leaves the list of direct

parameters. The inlet water temperature reappears on the

display.

Resetting alarms

When an alarm is detected, the following happens:

■

the buzzer is activated (if enabled by means of user

parameter

p4

),

■

the alarm relay is energized,

■

the display starts flashing, alternately showing the alarm code

and the inlet water temperature.

The following alarm codes may appear on the screen:

■

a1

: indicates an anti-freeze alarm,

■

e1

: indicates that the NTC probe used to measure the inlet

water temperature is defective,

■

e2

: indicates that the NTC probe used to measure the outlet

water temperature is defective,

■

ee

,

ep

: indicates that the EEPROM on the controller PCB inside

the unit is defective,

NOTE

In case of remote on/off control (

h7

=

1

), it is recom-

mended to install an on/off switch near the unit in

series with the remote switch. The unit can then be

switched off from either place.

NOTE

By pressing any button while the display is flashing

and cancelling of all changes is in progress, the can-

celling process is stopped, the display stops flashing

and the user can continue to change the settings.

NOTE

To reset the timers

c9

and

cv

, refer to chapter