EKHBRD011~Y1

Indoor unit for air to water heat pump system

4PW54465-1C

Installation manual

12

3

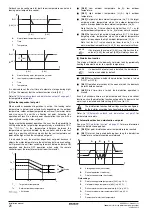

Using the table and instructions below, determine if the total

water volume in the installation is below the maximum allowed

water volume.

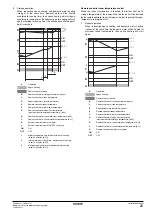

Calculating the pre-pressure of the expansion vessel

The pre-pressure (Pg) to be set depends on the maximum

installation height difference (H) and is calculated as below:

Pg=(H/10+0.3) bar

Checking the maximum allowed water volume

To determine the maximum allowed water volume in the entire circuit,

proceed as follows:

1

Determine for the calculated pre-pressure (Pg) the

corresponding maximum water volume using the graph below.

2

Check that the total water volume in the entire water circuit is

lower than this value.

If this is not the case, the expansion vessel inside the indoor unit is

too small for the installation.

Example 1

The indoor unit is installed 5 m below the highest point in the water

circuit. The total water volume in the water circuit is 100 l.

In this example, no action or adjustment is required.

Example 2

The indoor unit is installed at the highest point in the water circuit.

The total water volume in the water circuit is 380 l.

Result:

■

Since 380 l is higher than 180 l or 270 l, the pre-pressure must

be decreased (see table above).

■

The required pre-pressure is:

Pg=(H/10+0.3) bar=(0/10+0.3) bar=0.3 bar

■

The corresponding maximum water volume can be read from

the graph: approximately 380 l for leaving water of 65°C and

approximately 250 l for leaving water of 80°C.

■

In case of 65°C leaving water, since the total water volume

(380 l) is not higher than the maximum water volume (380 l), the

expansion vessel suffices for the installation.

In case of 80°C leaving water, because the total water volume

(380 l) is higher than the maximum water volume (250 l) of the

expansion vessel, an additional expansion vessel must be

installed.

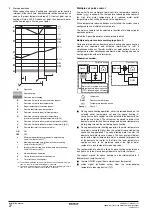

Setting the pre-pressure of the expansion vessel

When it is required to change the default pre-pressure of the

expansion vessel (1 bar), keep in mind the following guidelines:

■

Use only dry nitrogen to set the expansion vessel pre-pressure.

■

Inappropriate setting of the expansion vessel pre-pressure will

lead to malfunction of the system. Therefore, the pre-pressure

should only be adjusted by a licensed installer.

To be able setting the pre-pressure of the expansion vessel, the

switch box needs to be removed from the unit. How this must be done

is explained in the chapter

Connecting the water circuit

Water connections must be made. The location of the water inlet

connection and the water outlet connection on the indoor unit is

shown in the chapter

If air, moisture or dust gets in the water circuit, problems may occur.

Therefore, always take into account the following when connecting

the water circuit:

■

Use clean pipes only.

■

Hold the pipe end downwards when removing burrs.

■

Cover the pipe end when inserting it through a wall so that no

dust and dirt enter.

■

Use a good thread sealant for the sealing of the connections.

■

When using non-brass metallic piping, make sure to insulate

both materials from each other to prevent galvanic corrosion.

■

Because brass is a soft material, use appropriate tooling for

connecting the water circuit. Inappropriate tooling will cause

damage to the pipes.

Installation

height

difference

(a)

(a) Installation height difference: height difference (m) between the highest

point of the water circuit and the indoor unit. If the indoor unit is located at

the highest point of the installation, the installation height is considered 0 m.

Water volume

65°C

≤

270 l

80°C

≤

180 l

65°C >270 l

80°C >180 l

≤

7 m

No pre-pressure adjustment

required.

Actions required:

• pre-pressure must be

decreased, calculate

according to

the pre-pressure of the

expansion vessel"

• check if the water volume

is lower than maximum

allowed water volume

(use graph below)

>7 m

Actions required:

• pre-pressure must be

increased, calculate

according to

the pre-pressure of the

expansion vessel"

• check if the water volume

is lower than maximum

allowed water volume

(use graph below)

Expansion vessel of the unit

too small for the installation.

= pre-pressure

= maximum water volume

= increase pre-pressure vessel volume

= decrease pre-pressure vessel volume

0.3

0.5

1

0.0

1.5

2

2.5

100

50

0

20

150

200

250

300

350

400

450

maximum water volume [l]

pre-pressure [bar]

80

80

°

C

65

65

°

C

80

°

C

65

°

C

Be careful not to deform the unit piping by using excessive

force when connecting the piping. Deformation of the

piping can cause the unit to malfunction.

■

The unit is only to be used in a closed water system.

Application in an open water circuit can lead to

excessive corrosion of the water piping.

■

Never use Zn-coated parts in the water circuit.

Excessive corrosion of these parts may occur as

copper piping is used in the unit's internal water

circuit.

NOTE

When using a 3-way valve or a 2-way valve in the

water circuit, the maximum changeover time of the

valve shall be less than 60 seconds.

Содержание EKHBRD-AY1

Страница 43: ...V1 Y1 NOTES 5 5...

Страница 44: ...4PW54465 1C Copyright Daikin...