Installation manual

33

EKHBRD011~Y1

Indoor unit for air to water heat pump system

4PW54465-1C

M

AINTENANCE

AND

SERVICE

In order to ensure optimal availability of the unit, a number of checks

and inspections on the unit and the field wiring have to be carried out

at regular intervals.

This maintenance should be carried out by your local Daikin

technician.

To execute the maintenance

activities as mentioned below, it

is only required to remove the

front decoration panel.

To take away the front decoration

panel, remove the 2 bottom

screws and then unhitch the

panel.

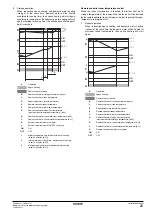

Maintenance activities

The described checks must be executed at least once a year by

qualified personnel.

1

Water pressure relief valve

Check for correct operation of the pressure relief valve by

turning the red knob on the valve counter-clockwise:

■

If you do not hear a clacking sound, contact your local dealer.

■

In case the water keeps running out of the unit, close both

the water inlet and outlet shut-off valves first and then contact

your local dealer.

2

Pressure relief valve hose

Check that the pressure relief valve hose is positioned

appropriately to drain the water.

3

Indoor unit switch box

Carry out a thorough visual inspection of the switch box and look

for obvious defects such as loose connections or defective

wiring.

4

Water pressure

Check if the water pressure is above 1 bar.

If necessary add water.

5

Water filter

Clean the water filter.

T

ROUBLESHOOTING

This section provides useful information for diagnosing and

correcting certain troubles which may occur in the unit.

This troubleshooting and related corrective actions may only be

carried out by your local Daikin technician.

General guidelines

Before starting the troubleshooting procedure, carry out a thorough

visual inspection of the unit and look for obvious defects such as

loose connections or defective wiring.

When a safety device was activated, stop the unit and find out why

the safety device was activated before resetting it. Under no

circumstances safety devices may be bridged or changed to a value

other than the factory setting. If the cause of the problem can not be

found, call your local dealer

.

If the pressure relief valve is not working correctly and is to be

replaced, always reconnect the flexible hose attached to the pressure

relief valve, to avoid water dripping out of the unit!

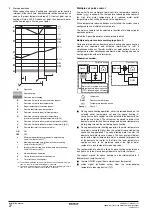

Opening the unit

■

To facilitate access to the air

purge valve, thermal cut-out,

3-way valve, thermistors,

field wiring duct, ..., the top

decoration panel of the unit

can be removed by

removing the 2 screws at the

rear and then unhitch the

panel.

■

In combination with

removing the top decoration

panel, the front decoration

panel can also be removed

to allow servicing the

manometer, pressure relief

valve, ... To remove the front

decoration panel, remove

the 2 bottom screws and

then unhitch the panel.

WARNING: ELECTRIC SHOCK

■

Before carrying out any maintenance or repair activity,

always switch off the circuit breaker on the supply

panel, remove the fuses or open the protection

devices of the unit.

■

Make sure that before starting any maintenance or

repair activity, also the power supply to the outdoor

unit is switched off.

■

Do not touch live parts for 10 minutes after the power

supply is turned off because of high voltage risk.

■

Additionally, measure the points as shown in

with a tester and confirm that the voltage of the

capacitor in the main circuit is no more than 50 V DC.

■

The heater of the compressor may operate even in

stop mode.

■

Please note that some sections of the electric

component box are hot.

■

Make sure you do not touch a conductive section.

■

Do not rinse the indoor unit. This may cause electric

shocks or fire.

Play it safe!

Touch a metal part by hand (such as the stop valve) in

order to eliminate static electricity and to protect the PCB

before performing service.

2x

When carrying out an inspection on the switch box of the

unit, always make sure that the main switch of the unit is

switched off.

2x

4x

2x

Содержание EKHBRD-AY1

Страница 43: ...V1 Y1 NOTES 5 5...

Страница 44: ...4PW54465 1C Copyright Daikin...