SERVICING

23

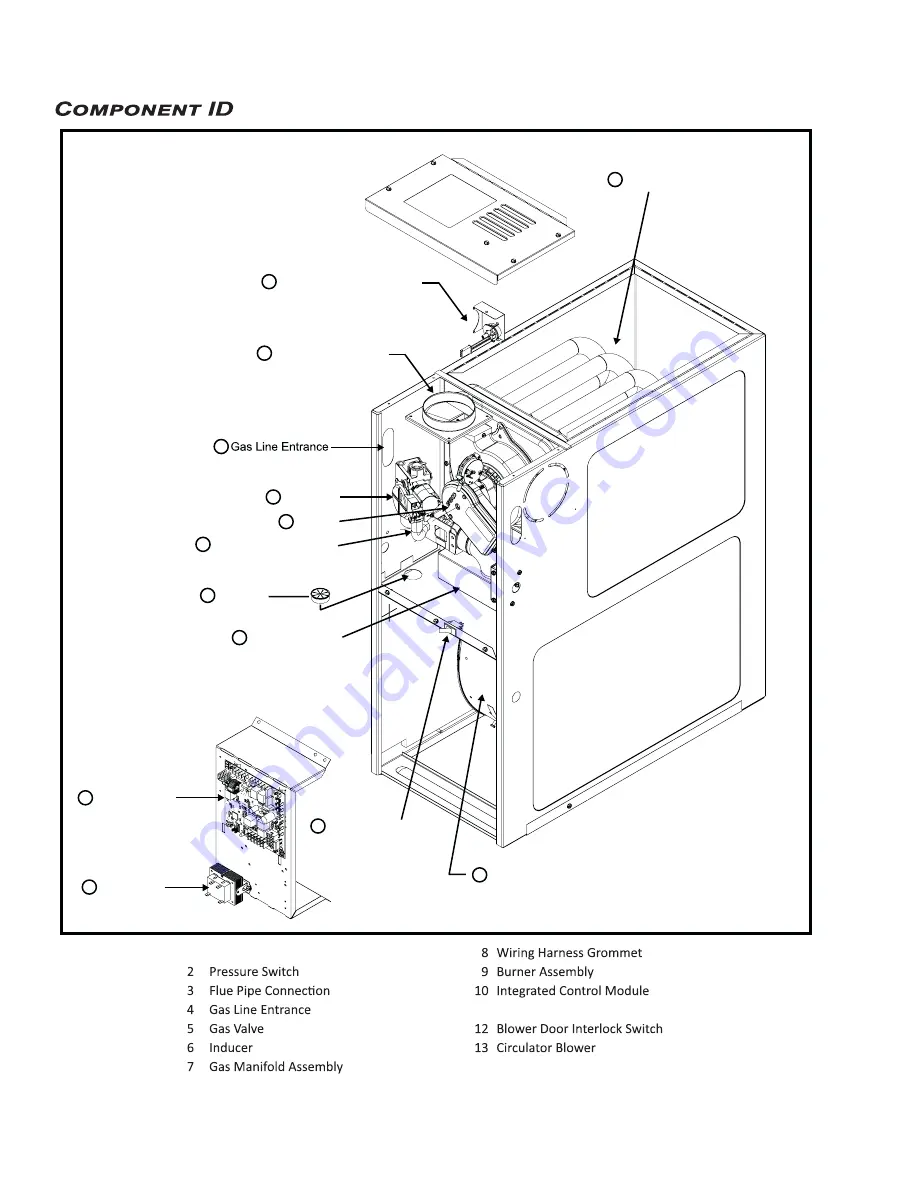

1 Tubular Heat Exchanger

11 T ransformer

T

ubular Heat Exchanger

Pressure Sensor A

ssembly

Flue Pipe Connection

Gas Valve

Inducer

Gas Manifold A

ssembly

Gromme

t

Burner A

ssembly

Integrated

Control Module

Tr

ansformer

Blower Door

Interlock Switch

Circulator Blower

1

2

3

4

5

6

7

8

9

10

11

12

13

Содержание DM80SE

Страница 15: ...TROUBLESHOOTING 15 DM80SE U...

Страница 16: ...TROUBLESHOOTING 16 DM80SE U...