- 8 -

All installation and management activities

must be carried out by qualified personnel.

Refer to the specific wiring diagram and

electrical component manual are attached

with the product before electrical

installation. Site contractor shall do

termination at site for wiring connection

between components that located at

different AHU sections and delivered

separately.

IMPORTANT

MAKE SURE ALL THE ELECTRIC

POWER

DISCONNECT

AND

SECURE

FROM

SWITCH

ON

BEFORE

DOING

WIRING

CONNECTION

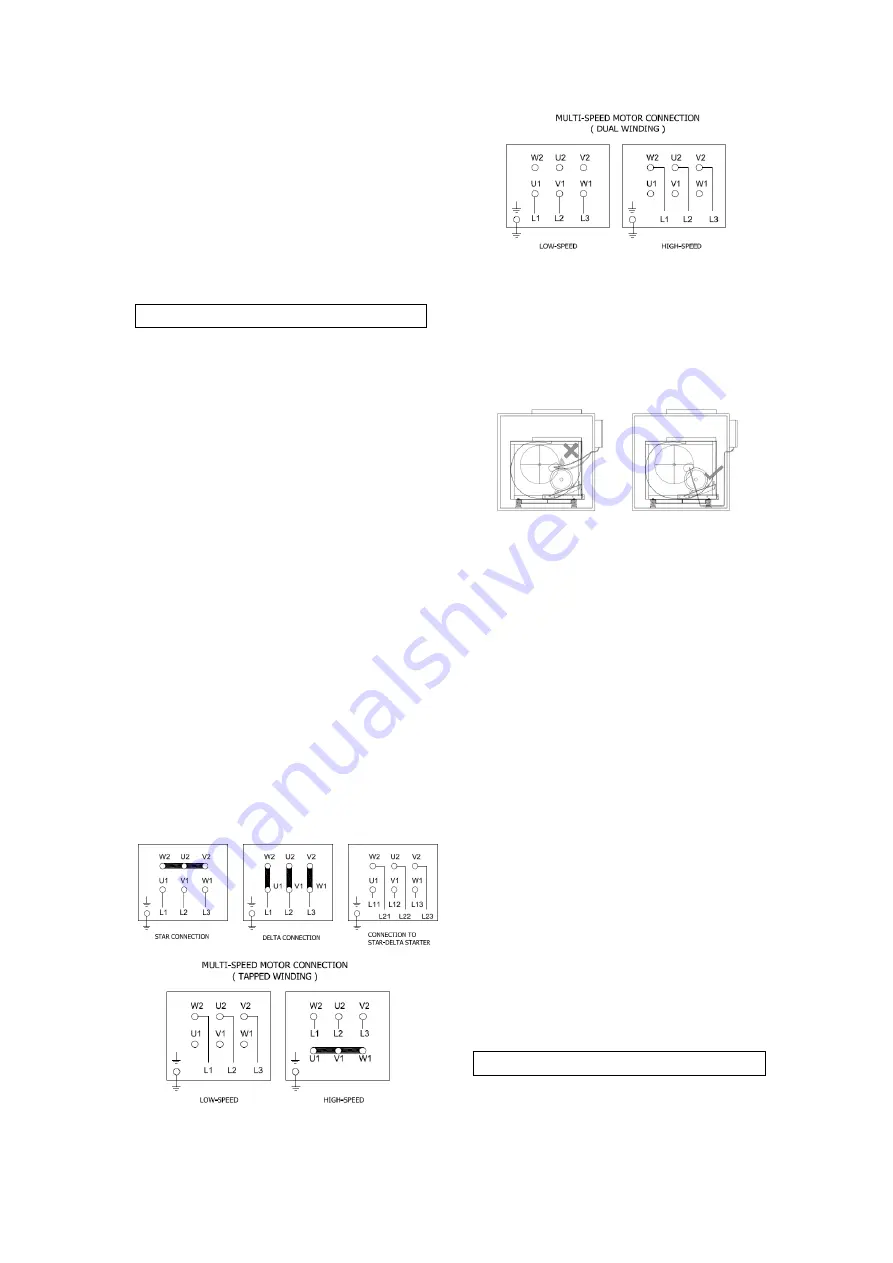

5.7.1 Motor Connection

The electric supply to the motor must

correspond to the rated voltage stated in

motor nameplate and be in conformance

with the National and Local Electric Code

and Regulations. Motor supplied able to

operate within 10% tolerance from the

nameplate voltage. Motor connection

details are contained in the cover of the

motor terminal box. (See Figure 22). The

fan section metal frame must be grounded.

Suitable electrical protection isolator

should be installed to protect the motor

and other electrical equipment.

Flexible conduit must be used when wiring

up fan motors to allow the fan motor to

move freely on its anti-vibration mounts.

Cables passing through panels must be

made with gland or grommet.

For inverter control, refer to the VFD

manual for wire size and requirements.

Figure 22 – 3 phases motor connection diagram

5.7.2 Motor Cabling

Motor wiring must go downward from

motor

terminal

box

to

prevent

condensation water flowing into motor

and lead to a failure. (See Figure 23)

Figure 23

–

Motor Cabling

5.8 Drive Belt & Sheave

Improper sheave alignment and belt

tension can cause excessive vibration,

premature failure of belts and bearings.

See Figure 24 for correct motor sheave

and fan sheave alignment.

Tensioning of the drive belt is achieved by

moving the motor in relation to the fan

(See Figure 25). When inserting new belts,

do not force belts over grooves, Loosen

the adjusting screw at motor base until

belt can slide smoothly over the grooves.

When all belts are in position, proceed to

adjust belt tension using the adjusting

screw and nuts on the motor base.

Use recognized belt tension gauge to

check the belt tension by apply a force

large enough at the center of the belt to

deflect the belt by 16mm per meter (See

Figure 26). The deflection force for any

belt should be within the minimum and

maximum force shown in table 1. Readjust

the tension to maximum value when it

drops to min. value. The deflection force

of factory setting is based on “Initial

Fitting”, re-tensioning as “Retension” after

the unit has run for 24 hours.

WARNING

OVER TENSION TOWARD DRIVE

BELT WILL CAUSE PREMATURE

FAILURE OF BELT AND BEARING

DAMAGE.