16

MODEL

SHEAVE

DIAMETER

(in)

DEFLECTION

(in)

BELT

DRIVE

Used

New

15 Ton B, BA Standard 4.3 to 5.5

5.5

+

.5

8.2

+

.5

1/4 ± 1/16

20 Ton B, BA Standard 4.3 to 5.5

5.5

+

.5

8.2

+

.5

1/4 ± 1/16

25 Ton B, BA Standard 5.1 to 6.1

5.5

+

.5

8.2

+

.5

1/4 ± 1/16

DEFLECTION

FORCE (lbs)

TYPE

RECOMMENDED POUNDS OF FORCE PER BELT

When new V-belts are installed on a drive the initial tension will

drop rapidly during the first few hours. Check tension frequently

during the first 24 hours of operation. Subsequent retensioning

should fall between the minimum and maximum force. To de-

termine the deflection distance from the normal position, use a

straightedge or stretch a cord from sheave to sheave to use as a

reference line. On multiple belt drives, an adjacent undeflected

belt can be used as a reference.

MOTOR SHEAVE ADJUSTMENTS

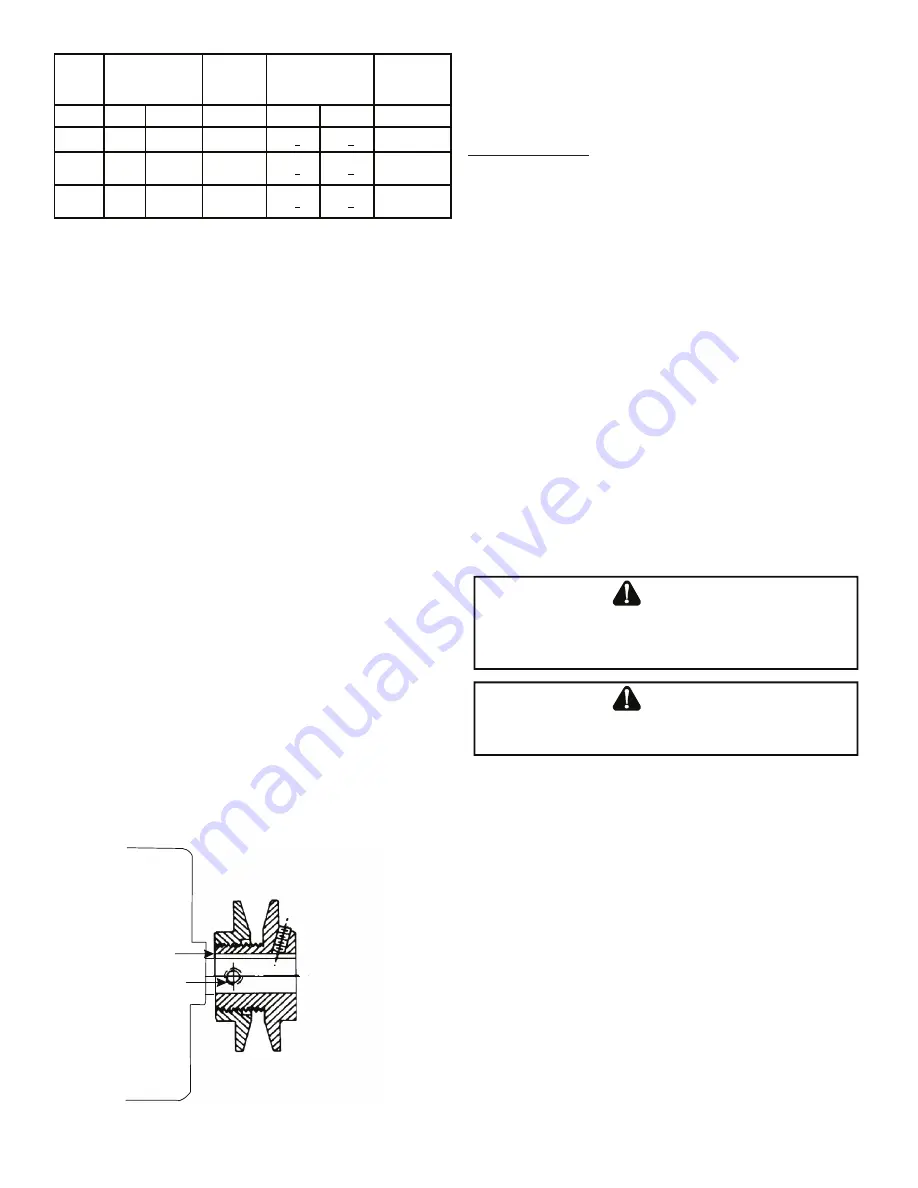

Vl, Vm & 2vp Variable Pitch Key Type Motor Sheaves

The driving and driven motor sheaves should be in alignment with

each other and the shafts parallel.

Vl & Vm Sheaves Adjustment

1. Loosen set screw “B” using a 5/32” Allen key.

2. Making half or full turns from closed position, adjust sheave

pitch diameter for desired speed. DO NOT OPEN MORE

THAN SIX FULL TURNS.

3. Tighten set screw “B” securely over flat.

4. Carefully put on belts and adjust belt tension. DO NOT

FORCE BELTS OVER GROOVES.

5. Ensure all keys are in place and the set screws tight before

starting drive. Recheck set screws and belt tension after

24 hours service.

NOTE:

Future adjustments should be made by loosening the belt

tension and increasing or decreasing the pitch diameter of the

sheave by half or full turns as required. Readjust belt tension before

starting drive.

C

B

VL & VM

NOTE:

Do not operate sheave with flange projecting beyond the

hub end.

GAS SYSTEM CHECK

Pre-Operation Checks

1. Close the manual gas valve external to the unit.

2. Turn off the electrical power supply to the unit.

3. Set the room thermostat to its lowest possible setting.

4. Remove the heat exchanger door on the side of the unit

by removing screws.

5. This unit is equipped with an ignition device which

automatically lights the main burner. DO NOT try to light

burner by any other method.

6. Move the gas control valve switch to the OFF position. Do

not force.

7. Wait five minutes to clear out any gas.

8. Smell for gas, including near the ground. This is important

because some types of gas are heavier than air. If you have

waited five minutes and you do smell gas, immediately

follow the warnings on page 3 of this manual. If having

waited for five minutes and no gas smell is noted, move

the gas control valve switch to the ON position.

9. Replace the heat exchanger door on the side of the unit.

10. Open the manual gas valve external to the unit.

11. Turn on the electrical power supply to the unit.

12. Set the thermostat to desired setting.

Gas Supply Pressures & Regulator Adjustments

S

HOULD

OVERHEATING

OCCUR

OR

THE

GAS

SUPPLY

FAIL

TO

SHUT

OFF

,

TURN

OFF

THE

MANUAL

GAS

SHUTOFF

VALVE

EXTERNAL

TO

THE

UNIT

BEFORE

TURNING

OFF

THE

ELECTRICAL

SUPPLY

.

WARNING

T

O

AVOID

PROPERTY

DAMAGE

,

PERSONAL

INJURY

OR

DEATH

,

DO

NOT

FIRE

GAS

UNIT

WITH

FLUE

BOX

COVER

REMOVED

.

WARNING

NOTE:

Except during brief periods when gas pressures are being

measured by qualified service personnel, the furnace access panel

must always be secured in place when the furnace is in operation.

An inspection port in the access panel is provided to monitor the

flame.

The first step in checking out the gas-fired furnace is to test the

gas supply piping to the unit for tightness and purge the system

of air using methods outlined in the latest edition of the National

Fuel Gas Code ANSI Z223.1. Verify that the disconnect switch is

in the “OFF” position. A soapy water solution should be used to

check for gas leaks. Since the unit is subject to considerable jarring

during shipment, it is extremely important that all gas connections

and joints be tested for tightness. Gas piping downstream from

the unit inlet should be checked for leaks during the subsequent

sequence check.

The supply gas pressure should be adjusted to 7.0” w.c. on natural

gas and 11.0” on LP gas with the gas burners operating. If there is

more than one unit on a common gas line, the pressures should

be checked with all units under full fire. A supply pressure tap is

Содержание DBG Series

Страница 29: ...29 APPENDIX D WIRING DIAGRAMS...

Страница 39: ...39 THIS PAGE INTENTIONALLY LEFT BLANK...